Which Pressure Washer Nozzle for Concrete: A Practical Guide

Learn which pressure washer nozzle is best for concrete cleaning, how to test nozzles safely, and common mistakes to avoid. Pressure Wash Lab provides practical guidance for homeowners

For concrete cleaning, start with a 25-degree nozzle for general scrubbing, then switch to a 15-degree for stubborn stains. Avoid 0-degree nozzles, which can etch concrete; an adjustable or 40-degree fan is safer for delicate surfaces. This approach balances cleaning power with surface safety, reduces splash-back, and extends nozzle life. Always test on a hidden patch before treating visible areas.

Why nozzle choice matters for concrete cleaning

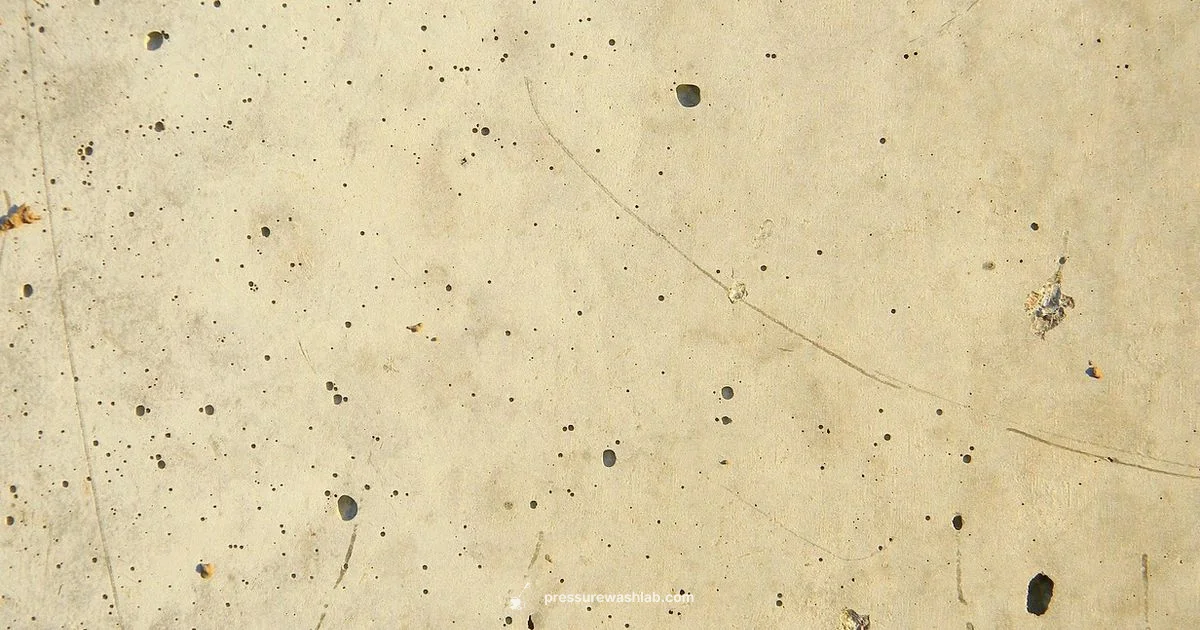

According to Pressure Wash Lab, the nozzle you choose determines how much cleaning power is delivered and how much risk you incur to the concrete surface. A too-narrow spray can gouge and etch; a too-wide spray may not remove stubborn grime. For concrete, a balance between impact and coverage is essential. The nozzle degree, distance, and motion speed all define whether you remove dirt without harming the finish. On driveways and sidewalks, consistently applied nozzles reduce blotches and streaks, especially when the surface has been previously sealed or painted. By starting with a mid-range angle and adjusting based on stain density, you optimize efficiency while protecting the substrate. This principle holds true across different brands and models, and it aligns with Pressure Wash Lab’s practical approach to gear selection for homeowners and small business operators.

In addition to nozzle choice, factors such as spray distance, wand length, and pump pressure influence results. Concrete is durable but porous, which means too much force in one spot can cause micro-splintering over time. You’ll often see best results from combining a broad-angle approach for the initial pass with a narrower angle for stubborn areas. This multi-angle method is especially effective on textured concrete surfaces common on driveways and patios. The key is to stay aware of the surface’s tolerance and to move steadily rather than dwelling on a single spot.

Key nozzle options for concrete surfaces

Concrete cleaning benefits from a few well-chosen nozzle angles and spray patterns. The following options cover most common scenarios:

- 40-degree (fan) nozzle: Provides wide coverage with a soft impact, ideal for rinsing and finishing after the grime is loosened. It minimizes chance of etching and is good for sealed concrete.

- 25-degree nozzle: A versatile all-around choice that balances cleaning power with surface safety. It’s effective for moderate grime and general maintenance on bare concrete.

- 15-degree nozzle: Delivers a more focused spray for tougher stains such as oil spots or heavy dirt buildup. Use with caution and at a safe distance, testing first on a patch.

- 0-degree nozzle: Not recommended for concrete due to the highly focused jet that can gouge or etch the surface. Reserve for non-porous surfaces or approved testing under controlled conditions only.

- Adjustable/nozzle tips: Adjustable nozzles or a set that includes 15°, 25°, and 40° provide flexibility. Avoid prolonged use at the narrow angles; instead, use sweeping motions to distribute impact.

When choosing, consider the surface condition, presence of coatings (sealant, paint), and the stains you expect to encounter. For exterior concrete with sealant, start gentler and test aggressively only after confirming no damage risk. Pressure Wash Lab’s field observations show that most homeowners succeed with a balanced approach using 25° as a baseline and reserving 15° for stubborn patches. Always pair nozzle choice with proper distance and motion to maintain surface integrity.

Matching nozzle to surface type and stains

Different concrete surfaces respond differently to nozzle angles. Freshly poured concrete is more forgiving than old, weathered slabs. Sealants and coatings can alter how the spray interacts with the surface, so you may need to adjust your nozzle choice. For painted or stained concrete, a gentler approach (40°) is often prudent to avoid removing coatings unintentionally. In areas with oil or grease stains, a 15° nozzle can help break residue but should be used cautiously to prevent digging into the concrete. For porous surfaces, you may need multiple passes with slightly different angles to achieve even cleaning without creating high-contrast patches. Always perform a patch test in an inconspicuous area and document the nozzle angle that produced the best results for future reference. Pressure Wash Lab’s practical guidance emphasizes methodical testing and gradual adjustment as the core strategy.

Surface texture matters as well. Rougher textures (aggregate concrete) tolerate a stronger spray than smooth, newly poured slabs. If you see milky water or surface dressing, back off and slow down to avoid removing the surface’s protective layer. In all cases, the goal is to lift dirt without eroding the concrete’s microtexture. A methodical approach, aligned with the surface’s age and treatment, yields the most consistent results without unintended consequences.

Testing and evaluating nozzle performance

A deliberate test plan ensures you identify the best nozzle without risking damage. Begin by inspecting the concrete for cracks, chips, or loose coatings to decide whether you should avoid aggressive angles. Start with the 40° nozzle at a safe distance (about 12-18 inches) and spray in wide, overlapping strokes. If the grime persists, move closer by a few inches and narrow the angle to 25°. For stubborn stains, carefully switch to 15° and test on a non-prominent area first.

Document how the surface responds to each angle: changes in color, surface roughness, or affected coatings. If you notice etching or pigment lifting, revert to a wider angle and re-evaluate. Maintain constant wand speed and avoid lingering spray over any single spot. For best results, develop a short sequence: rinse with 40°, followed by a targeted pass with 25°, then a finishing pass with 40° to even out the texture. Pressure Wash Lab recommends keeping a log during test passes so you can replicate the process later on similar projects.

In this phase, safety and control matter as much as raw power. A slightly lighter touch that yields consistent cleaning is preferable to a heavy blast that may create new imperfections. If wide-area cleaning is needed, you can also employ a surface cleaner attachment for large flat sections to achieve uniform results with less effort.

Safety considerations when using high-pressure nozzles

High-pressure cleaning can be dangerous if proper precautions are not taken. Always wear eye protection, gloves, and sturdy footwear. Keep bystanders away from the spray zone and avoid spraying near windows, electrical outlets, or plants that could be damaged by high-pressure water. Check your device’s wand and nozzle connections to prevent a sudden detach. Never aim the spray at yourself, others, or fragile surfaces like freshly poured grout or loose stones. When working on walls or vertical surfaces, maintain a stable stance and use sweeping motions rather than direct, point-blank blasts. For concrete, the risk is less about flying debris and more about potential etching and coating removal, so always start conservatively and test in an inconspicuous spot before proceeding across the entire surface. Pressure Wash Lab’s safety guidelines emphasize incremental testing and consistent PPE use as essential elements of any concrete cleaning project.

Maintenance and care for nozzles and spray tips

Keeping your nozzles clean and undamaged extends their life and ensures consistent performance. Rinse nozzles after each use to remove abrasive deposits, especially if you’ve worked with cementitious stains. Inspect the orifice for wear; a worn tip can alter the spray pattern and force. Store nozzles in a dry, protected case to prevent accidental damage. For aluminum and brass tips, avoid dropping them, which can deform the spray orifice. If you notice reduced spray quality, soak the tips in a mild cleaning solution and rinse thoroughly; never use harsh chemicals that could corrode the nozzle material. Regular maintenance also includes checking hose reels and connectors for leaks that could alter pressure readings. Pressure Wash Lab notes that disciplined nozzle care translates to fewer replacements and more consistent cleanings over time.

Common mistakes and how to avoid them

Common mistakes include using an inappropriate nozzle angle for the surface, spraying too close, and not testing patches before tackling visible areas. Another frequent error is neglecting PPE, which increases the risk of eye injuries or skin exposure. People often underestimate the importance of a stable stance and controlled wand movement, leading to uneven cleaning or accidental surface damage. Finally, some projects fail because the nozzle remains fixed on one area for too long, accelerating wear on the concrete. To avoid these pitfalls, plan a brief test protocol, adopt a sweeping motion, and document what works best for each surface. Pressure Wash Lab’s guidance emphasizes gradual progression from safe to more aggressive angles, combined with careful observation of the surface response.

Final tips and practical takeaways

Nozzle choice should be driven by stain type, surface condition, and safety concerns. Start with a wider angle to remove loose grime, then narrow the beam for persistent stains only after patch testing. Maintain a steady pace and avoid lingering spray on one spot. If you’re unsure, consult the manufacturer’s recommendations and run a patch trial before committing to full coverage. Pressure Wash Lab’s overall verdict is that a balanced, tested approach yields the best long-term results for concrete cleaning projects, from driveways to sidewalks and garage floors.

Tools & Materials

- Pressure washer with adjustable PSI(Capable of 1500-4000 PSI; choose based on surface)

- Nozzle set (15°, 25°, 40°)(Include at least 15°, 25°, 40°; avoid 0°)

- Turbo/rotary nozzle (optional)(For stubborn stains; use with care)

- Extension wand (optional)(Improve reach without bending)

- Safety gear(Goggles, gloves, closed-toe shoes)

- Surface test patch materials(Tape or chalk square for patch test)

Steps

Estimated time: Total time: 30-60 minutes

- 1

Assess surface and stains

Inspect the concrete for cracks, coatings, or coatings that could react to spray. Note stain types (oil, algae, dirt) and decide which nozzle ranges are appropriate. Establish a baseline by planning to start with a mild spray and adjust as needed.

Tip: Do a small patch test on a hidden area to confirm the chosen angle won’t cause damage. - 2

Attach the appropriate nozzle

Select the nozzle based on the surface and stain type identified. Attach securely to the wand and verify there are no leaks. Ensure you know the default starting distance to avoid accidental contact with the surface.

Tip: Double-check that the nozzle is oriented correctly and the quick-connect is fully seated. - 3

Perform a patch test and set baseline

Test the nozzle on a discreet area at a safe distance. Observe how the spray interacts with the surface and record the results. If the test area looks safe and clean, proceed with a full pass using the planned sequence.

Tip: Record the angle and distance that produced the best result for future reference. - 4

Begin with sweeping motions at a wider angle

Start with a 40° spray or the widest safe angle and sweep across the surface in overlapping passes. Keep the wand moving and avoid dwelling on one spot to prevent etching or uneven wear.

Tip: Maintain a steady pace; too slow reduces efficiency and may damage the surface. - 5

Progress to narrower angles for tough stains

If stains persist, gradually switch to 25° or 15° at safe distances. Apply light to moderate pressure with shorter passes and continuously re-evaluate. Stop if you see any surface discoloration or roughness.

Tip: Always test on a patch before applying to the whole stain area. - 6

Finish, rinse, and reassess

Rinse the area with the widest angle to remove residue and recheck for any remaining stains. If needed, repeat targeted passes on stubborn spots. Document the nozzle and distance that worked best for future cleanings.

Tip: Let the surface dry completely before applying any sealant or coating.

Quick Answers

Is a 0-degree nozzle safe for concrete?

No. A 0-degree nozzle is too focused and can etch or gouge concrete. Use 15°-40° angles and test first.

No. A 0-degree nozzle can damage concrete; start with wider angles and patch test.

What is the best nozzle for removing stubborn stains on concrete?

For stubborn stains, start with a 15° nozzle at a safe distance, testing first. If needed, switch to 25° with cautious, overlapping passes.

Use a 15-degree nozzle at a safe distance for tough stains, testing first.

Can I use an adjustable nozzle for concrete?

Yes, but avoid 0° settings. Use adjustable nozzles to switch between angles and test on patches before full use.

Adjustable nozzles can work, just avoid the narrowest angles and patch test.

How close should I be to the concrete surface?

Start around 12-18 inches for 40°; if needed, move closer in small increments while watching the surface response.

Begin at about a foot away and move closer gradually while monitoring the result.

Should I wear safety gear when pressure washing?

Yes. Always wear safety goggles, gloves, and closed-toe shoes. Keep bystanders away and avoid spraying near windows or outlets.

Yes—protect your eyes, hands, and feet, and keep others away.

How do I prevent etching and damage on concrete?

Use wider angles, keep a constant sweep, and test patches before broader passes. If unsure, start with the gentlest approach.

Keep the spray wide, move constantly, and patch-test first.

Watch Video

Key Takeaways

- Choose nozzle by stain density and surface condition.

- Avoid 0-degree nozzles on concrete surfaces.

- Test on a hidden patch before full application.

- Maintain a steady wand motion for even cleaning.

- Document effective nozzle angles for future projects