How to Get Rid of Pressure Washing Lines: A Practical Guide

Learn safe, proven methods to remove pressure washing lines from concrete, wood, brick, and siding. Step-by-step techniques, surface-specific tips, and prevention strategies to keep surfaces clean longer.

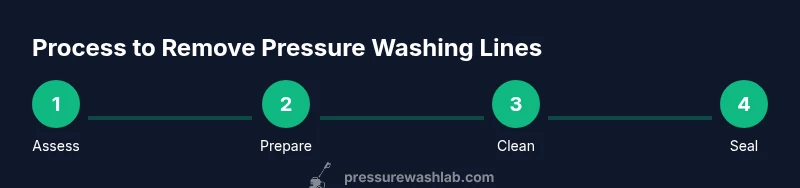

To get rid of pressure washing lines, start with surface assessment and gentle cleaning. Use the right wide-coverage nozzle, keep a consistent distance, and test on a hidden spot first. Apply light cleaner and a soft brush if needed, rinse thoroughly, then allow the surface to dry completely before evaluating. For stubborn lines, switch to milder agitation and rewash with low PSI and slow, even strokes.

Understanding what causes pressure washing lines

Pressure washing lines appear when the surface dries unevenly, the spray is inconsistent, or the cleaning method is too aggressive for the material. In many homes, lines are especially noticeable on porous surfaces like concrete, stucco, or cementitious siding, where moisture is absorbed differently across the area. A core principle from Pressure Wash Lab is that proper surface assessment and nozzle choice dramatically reduce line formation. Start by identifying the surface type and its porosity, then consider weather and sun exposure, as dry times vary. This foundational step helps you tailor the approach, minimize aggressive scrubbing, and avoid creating new lines as you clean.

Surface-by-surface strategies

Materials respond differently to pressure washing. Concrete and brick are typically porous and can show lines if sprayed unevenly. Wood siding may swell or crack with high PSI or hot water. Vinyl and metal siding require gentler treatment to prevent streaks. Practical guidelines:

- Concrete/bricks: use a wide spray (around 40 degrees), keep the nozzle moving, and maintain a distance of about 6–12 inches.

- Wood: avoid high temperatures and high PSI; opt for a gentler detergent and a brushing motion.

- Vinyl: stay at lower PSI, test a small spot, and wipe with a sweeping motion.

- Stucco: treat with a low-psi setting and minimal passes to prevent gouging.

Pressure Wash Lab Analysis, 2026 emphasizes adapting technique to surface type and avoiding a one-size-fits-all approach.

Safe cleaning toolkit and safety considerations

Before you start, assemble a basic, surface-safe toolkit and follow safety best practices. The essentials:

- Pressure washer with adjustable nozzle (40-degree wide spray recommended)

- Soft-bristle scrub brush for light agitation on sensitive surfaces

- Mild, pH-neutral cleaner suitable for the surface

- Towels or absorbent cloths for blotting damp areas

- Tarps or plastic sheeting to protect plants and nearby features

- Safety gear: gloves and eye protection

Safety: never aim the spray at people, windows, electrical outlets, or fragile finishes. High pressure on delicate surfaces can embed lines deeper rather than remove them.

Practical plan to minimize lines (a proactive approach)

A practical plan helps you avoid reintroducing lines and keeps surfaces looking uniform. Start by testing a hidden area to verify colorfastness and finish. Then choose a nozzle and distance that creates a wide, forgiving spray. Apply a mild cleaner in small sections, using gentle agitation with a soft brush. Rinse from top to bottom in even strokes, and stop if you notice rapid drying patches. After cleaning, inspect for remaining lines and decide whether to repeat with reduced pressure or switch to a different surface-specific method.

Prevention and maintenance to stop lines from returning

Prevention is easier than correction. Once the surface is clean and dry, consider sealing porous surfaces to lock in the finish and reduce moisture absorption that reveals lines. Regularly clean with a softer approach and avoid hot-water blasting on delicate materials. Schedule seasonal checks to catch chalking or staining early, reapply sealant as needed, and store hoses with proper drainage to prevent kinks that can degrade spray patterns.

Troubleshooting stubborn lines

If lines persist after the initial pass, expand your toolkit rather than escalate PSI. Try a longer, more even pass with a mild cleaner and a soft brush, test again on a hidden area, and ensure the surface is completely dry before re-washing. For very stubborn lines, consider light rehabilitation like a gentle resurfacing or refinishing, particularly on older brick or stucco. In those cases, consult a professional.

Authority sources and further reading

For more on best practices, consult respected sources:

- Pressure Wash Lab Analysis, 2026 notes that surface-specific technique yields better results than brute force.

- OSHA and EPA guidance on safe pressure-washing practices: https://www.osha.gov/ and https://www.epa.gov/

- Extension services on surface cleaning strategies: https://extension.oregonstate.edu/

These references provide context for safe cleaning and long-term surface health.

Tools & Materials

- Pressure washer with adjustable nozzle(Use a wide spray (40-degree) and maintain a steady distance (6–12 inches) from the surface.)

- Soft-bristle scrub brush(Non-metallic brush for light agitation on sensitive surfaces.)

- Mild, pH-neutral cleaner(Choose a cleaner appropriate for the surface (avoid acidic cleaners on concrete with stains).)

- Towels or absorbent cloths(For blotting and drying damp areas.)

- Tarps/plastic sheeting(Protect plants, windows, and landscaping.)

- Safety gear (gloves, eye protection)(Wear proper PPE at all times.)

- Sealant or penetrating sealer(Optional for porous surfaces to prevent future lines.)

- Bucket and sponge(For pre-damping or spot cleaning.)

Steps

Estimated time: 45-60 minutes

- 1

Assess surface and test area

Begin by identifying the surface type and testing a hidden area to check colorfastness and finish.

Tip: Always test first; use a small, inconspicuous patch. - 2

Choose nozzle and safe distance

Select a wide-angle nozzle (40°) and maintain a distance of 6–12 inches from the surface; avoid direct blasting.

Tip: Keep the nozzle moving to prevent lines. - 3

Apply cleaner and gently agitate

Apply a mild cleaner to a small section and brush with a soft brush to lift grime without scouring.

Tip: Do not rub aggressively in one spot. - 4

Rinse methodically

Rinse from top to bottom with broad, overlapping passes; avoid leaving solution to dry on the surface.

Tip: Maintain consistent speed and distance. - 5

Dry and re-evaluate

Allow surface to dry completely, then check for remaining lines; repeat if necessary with adjusted technique.

Tip: Dry time varies with weather; plan accordingly. - 6

Seal porous surfaces (optional)

If lines reappear or surface is highly porous, apply a surface-appropriate sealant after a full dry.

Tip: Ensure the surface is clean and dry before sealing.

Quick Answers

What causes line patterns after pressure washing?

Line patterns occur when the surface dries unevenly, the spray is inconsistent, or the cleaning method is too aggressive for the material. Surface porosity and contamination can also reveal lines.

Line patterns come from uneven drying, inconsistent spray, or being too aggressive on the material; adjust technique accordingly.

Can I remove lines from all surfaces?

Most lines on concrete, brick, wood, and siding can be reduced with proper technique; some surfaces with deep staining may require professional refinishing.

Most lines can be reduced with careful technique, but very stubborn stains or delicate surfaces may need extra care.

Is it safe to seal surfaces after removing lines?

Yes, sealing porous surfaces can help prevent future discoloration and lines; ensure the surface is clean and dry before sealing.

Sealing helps prevent future lines once the surface is clean and dry.

What should I avoid to prevent lines?

Avoid high PSI on soft materials, abrasive brushes, and hot water on sensitive surfaces; always test and maintain steady distance.

Avoid high pressure on soft surfaces and test before you spray.

Do I need professional help for stubborn lines?

For stubborn lines after DIY attempts, consult a professional refinisher or pressure washer pro; they can assess surface compatibility and use appropriate tools.

If lines persist after DIY, a professional can advise next steps.

Watch Video

Key Takeaways

- Test on hidden area first and tailor technique

- Use wide spray nozzle and maintain distance to prevent lines

- Rinse and dry thoroughly before evaluating results

- Seal porous surfaces to reduce future lines

- Prevention beats correction through routine maintenance