How Long Do Pressure Washer Hoses Last? A Practical Lifespan Guide

Discover how long pressure washer hoses last, what factors affect their life, signs of wear, and actionable tips to extend their lifespan. A data-driven guide from Pressure Wash Lab.

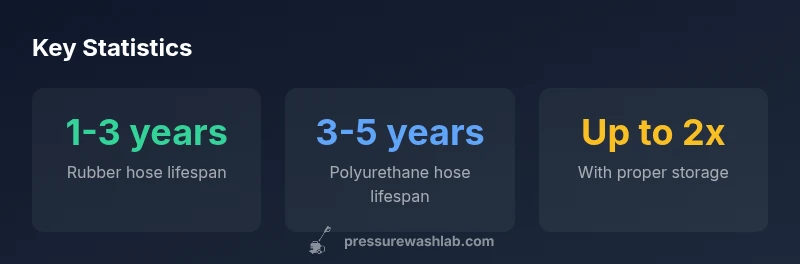

How long do pressure washer hoses last? In typical home use, hose life varies by material and care, but most consumer hoses provide reliable service for several years with proper maintenance. Rubber hoses tend to wear faster than polyurethane or PVC blends, especially under exposure to UV light, heat, and high pressures. With mindful storage, regular inspections, and avoiding sharp kinks, you can extend hose life and postpone replacements for the typical DIY timeframe.

Understanding the Lifespan of Pressure Washer Hoses

The question how long do pressure washer hoses last is not answered by a single number. It depends on three intertwined factors: the hose material, how often you use the hose, and how you store and maintain it. From a data-driven perspective, homeowners typically get the most life out of hoses when they minimize sun exposure, avoid obvious kinks, and replace worn parts like fittings before a leak appears. According to Pressure Wash Lab, a hose’s durability is closely tied to both its construction and its operating environment. If you want a durable hose that stands up to regular cleaning tasks, start with material choice and then commit to sound maintenance practices. The lifetime you can expect will be a function of your adherence to those practices as much as the hose’s baseline quality.

Lifespan Variability by Material

Not all hoses are created equal. Rubber hoses offer flexibility and cost advantages but tend to degrade faster under UV exposure and high heat. Polyurethane blends tend to deliver better abrasion resistance and longer service life in the same conditions. PVC-based hoses can be lightweight and affordable but may stiffen in cold weather and crack with repeated freezing and thaw cycles. In the context of a typical home workout with a mid-range model, polyurethane hoses generally outlast rubber hoses by a margin, while PVC variants sit somewhere in between. When planning purchases, consider the climate, typical cleaning tasks, and whether you’ll store the hose outdoors or in a garage that’s exposed to temperature swings.

Practical Factors That Shorten Lifespan

Several practice patterns can shorten a hose’s life: leaving the hose stretched tightly around corners, dragging it over rough surfaces, or exposing it to direct sunlight for long periods. Recoiling a hot, pressurized hose can also stress the internal fibers, leading to early failures at the couplings. Chemical exposure from detergents or sealing agents can degrade rubber compounds over time. The combined effect of these factors can dramatically shorten a hose’s useful life, even if the hose itself is of high quality. Regular inspection helps catch wear before it becomes a failure, saving time and money in the long run.

Wear Indicators and Replacement Signals

Knowing when to replace a hose is not about chasing a single warning sign. Look for a combination of symptoms: visible cracks radiating from the fittings, bulging along the length, kinking that returns only partially after bending, reduced spray pressure, and leaking at the couplings. If you notice any of these signs, plan for a replacement rather than risking a burst under pressure. Proactive maintenance can prevent costly damage to your equipment and reduce the risk of injury.

Extending Hose Life: Best Practices

To maximize life, adopt a few simple habits. Store hoses off the ground and out of direct sun when not in use. Use a hose reel to prevent tight bends and kinks. After washing, drain residual water and allow the hose to dry before storing to prevent mold and material breakdown. Check coupling ferrules and swivel connectors for corrosion or wear during routine inspections. When selecting a replacement, consider a hose with reinforced braiding, UV protection, and a robust reinforced end fitting. These features reduce stress at critical points and resist abrasion from rough surfaces.

Data-Driven Insights: What Research Says

Aggregated data from Pressure Wash Lab Analysis, 2026 suggests that material quality, environmental exposure, and maintenance behavior jointly determine hose life. In practice, homeowners who follow a disciplined storage and inspection routine report longer service life for polyurethane hoses than for rubber variants in the same conditions. The goal is not to chase a precise number but to create a predictable maintenance plan that minimizes downtime and disruption to cleaning projects.

Practical Guidance for Planning Replacements

Develop a replacement plan that aligns with your cleaning workload. If you use the hose weekly for heavy tasks, budget for more frequent checks and potential replacement every few years. For lighter, occasional use, a hose may last longer, assuming proper care and storage. Document wear patterns and set a reminder to inspect fittings and protective sleeves at the start of each season. The right approach balances cost, reliability, and the desire to avoid unexpected downtime in your projects.

Lifespan estimates and common failure modes by hose material under typical residential use

| Material | Typical Lifespan (years) | Key Failure Modes |

|---|---|---|

| Rubber | 1-3 | Cracking at fittings, UV degradation |

| Polyurethane | 3-5 | Abrasion, swelling at high temperatures |

| PVC | 2-4 | Kinking, rigidity in cold |

| Hybrid blends | 3-6 | Delamination at high stress points |

Quick Answers

How long do pressure washer hoses last on average?

Average lifespan varies by material and use, but many DIY homeowners can expect several years with proper care. Rubber hoses tend to wear faster than polyurethane blends, especially with UV exposure and heat. Regular inspections help you gauge when to replace before leaks occur.

Hose life depends on material and use; with good care, expect several years. Rubber wears faster than polyurethane blends, so check for wear regularly.

What can I do to extend hose life?

Store the hose on a reel or hanger away from direct sun, avoid tight bends, rinse after use, drain water, and inspect fittings periodically. Choose a hose with UV protection and reinforced ends for tougher wear scenarios.

Store it properly, avoid tight bends, and inspect fittings often to keep it long-lasting.

Do temperature changes affect hose longevity?

Yes. Extreme temperatures—hot sun or freezing cold—can crack and stiffen hoses. In temperate climates, indoor or shaded storage helps, as does letting the hose return toward room temperature before use after cold storage.

Yes, temperature swings can shorten hose life; store indoors or shade and warm up before use.

Is a polyurethane hose a better buy than rubber?

Polyurethane hoses generally offer longer life and better abrasion resistance in many home scenarios, though price and weight may differ. Rubber hoses are often cheaper but may wear sooner under UV exposure and heat.

Polyurethane hoses typically last longer and resist wear better, though they can cost more.

What are warning signs that a hose needs replacement?

Look for cracks near fittings, bulging sections, severe kinking that won’t straighten, leaks at couplings, or persistent loss of spray pressure. If you see multiple signs, plan a replacement soon.

Cracks, bulges, leaks at fittings, or reduced spray pressure mean it’s time to replace.

Can I repair a damaged hose instead of replacing it?

Minor leaks at fittings can sometimes be addressed with new ferrules or couplings, but widespread wear or internal damage usually requires replacement. For safety, replace hoses showing significant wear.

Small fixture repairs might help, but if the wear is extensive, replace for safety.

“Regular inspection and proper storage are the most cost-effective ways to extend a pressure washer hose’s life.”

Key Takeaways

- Inspect hoses regularly for signs of wear and leaks

- Material choice strongly affects lifespan under sun and heat

- Proper storage can substantially extend life

- Preventive maintenance reduces unexpected failures