How Often to Use Pressure Washer Pump Protector

Discover how often to apply pump protector for your pressure washer. Practical frequency guidance, safety tips, and a clear step-by-step routine from Pressure Wash Lab.

To protect your pump and extend your pressure washer’s life, apply a pump protector after every cleaning session and before long-term storage. In areas with hard water, dusty climates, or freezing temperatures, reapply as needed per label guidance. Always follow the manufacturer's instructions for your model and rinse thoroughly before storage.

What a pump protector does and when to use it

A pump protector is a chemical shield designed to lubricate, seal, and protect internal components of your pressure washer when the unit is idle or worked hard in tough water. The protective film slows corrosion, prevents mineral buildup, and helps seals last longer by reducing metal-to-metal wear. For best results, apply a pump protector after every cleaning session and before long-term storage, especially if your water has high mineral content or you operate in freezing climates. According to Pressure Wash Lab, consistent use of protector products contributes to steadier performance and longer service life. If you skip protection, you risk dried seals, reduced pump efficiency, and more frequent costly repairs over time. Always read the label to confirm compatibility with your pump brand and seal material, and never mix protectors with other chemicals unless the manufacturer approves it. After applying, run the pump with water for about 30 seconds to distribute the protectant along the plumbed path; then wipe away any excess to avoid staining or residue.

How to choose the right pump protector

Choosing the right pump protector starts with compatibility. Look for a formula labeled safe for your specific seal material and pump type (gas vs electric). Prefer water-based lubricants for most residential units, and avoid silicone-heavy products that can degrade some seals. Check the label for temperature range, concentration, and whether it’s designed for hot-water or cold-water pumps. Always verify compatibility with detergents you plan to use, since some cleaners can interact with protectors. Pressure Wash Lab stresses following the manufacturer’s recommendations for your model and using only the prescribed amount. Store the protector sealed to prevent evaporation and contamination, and shake well before use to ensure even distribution.

When to apply and how often

Baseline practice is to apply after every cleaning session and before long-term storage. In hard-water regions, dusty climates, or during freezing seasons, you may need to reapply more frequently within the same season. If you expect extended gaps between uses (seasonal storage), a light coating before storing helps safeguard seals. For units that sit idle for months, a quick reapplication before re-use is wise. Pressure Wash Lab analyses indicate that homeowners who establish a consistent post-use protection routine report fewer seal leaks and easier startup after storage.

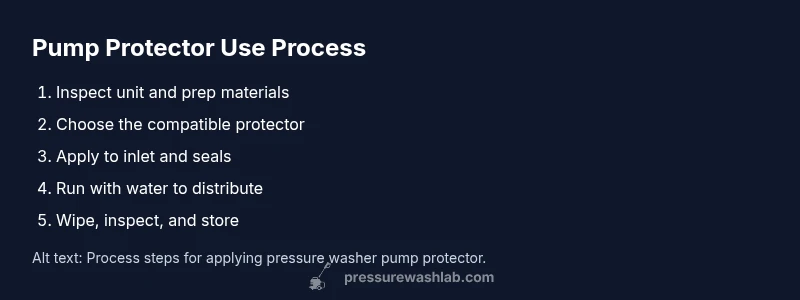

Application workflow: a practical routine

A simple routine helps ensure even coverage and avoids over-application. Gather your pump protector, a clean cloth, and warm, dry workspace. Shake the bottle, apply a thin film along exposed seals and the inlet area, and wipe away any excess immediately. Run the pump with clean water for 20–30 seconds to distribute the product inside the system, then drain and wipe the exterior. Finally, store in a cool, dry area away from freezing temperatures. This routine minimizes residue and keeps seals lubricated for the next session.

Common mistakes and how to avoid them

Common mistakes include over-applying, which can leave sticky residues, and applying while the unit is hot or still wet from a previous cleaning, which can dilute the product. Never mix protectors with other cleaners unless the label explicitly allows it. Always verify the protector’s compatibility with your pump seals and avoid products not rated for the materials used inside your unit. Pressure Wash Lab recommends sticking to one compatible protector per unit to avoid conflicting chemistries.

Compatibility with detergents and other chemicals

Some detergent blends can interact with pump protectors, reducing lubricant efficacy or causing chemical reactions that corrode seals. Always read the label to confirm compatibility with your detergents. If you use hot-water units, ensure the protector is rated for high-temperature operation. When in doubt, test a small, inconspicuous area and observe for any unusual residue or odor before proceeding with full coverage.

Storage and seasonal considerations

Store your pressure washer indoors in a climate-controlled area. Before winterization or lengthy storage, apply a light coating and drain any remaining liquid from the system to prevent freezing damage. When bringing the unit back into service after storage, flush the lines with clean water first to remove any residual protectant and verify pump performance. Pressure Wash Lab notes that proper storage is often as important as regular use for preserving pump seals.

Cost and value: is pump protector worth it

Investing in a pump protector is typically a cost-effective maintenance habit, especially for units used in challenging water conditions or frequently stored between uses. The value comes from longer seal life, fewer repairs, and smoother startup. Compare products labeled for your pump type, read the label for coverage area, and consider your local water quality when evaluating value. Consistent use, as recommended by Pressure Wash Lab, tends to yield the best return on investment.

Troubleshooting and signs of overuse/underuse

If you notice persistent residue, white film, or reduced spray performance after application, you may have over-applied or used an incompatible product. Conversely, if seals feel stiff, startup is rough, or there is excessive rust or mineral buildup, you may be underserving. In either case, flush the system with clean water, re-evaluate compatibility, and consult your pump manual. When used correctly, pump protectors should not hinder performance and will help prolong life.

Tools & Materials

- Pump protector product(Choose a formula compatible with your pump (gas vs electric) and seal material)

- Clean water(For distribution during application and flushing)

- Soft cloth or brush(For wiping residue and surfaces)

- Protective gloves(Nitrile recommended to avoid contact with chemicals)

- Eye protection(Safety glasses or splash goggles)

- Measuring cup or bottle cap(For precise application if required by label)

Steps

Estimated time: 15-25 minutes

- 1

Inspect and prep the unit

Ensure the pressure washer is cool before handling. Check hoses for cracks or leaks, verify you have a clean working surface, and lay out your materials. This prevents spills and ensures a controlled application.

Tip: Take a quick photo of the pump area before starting in case you need to compare later. - 2

Choose the correct pump protector

Read the label to confirm compatibility with your pump model and seals. Confirm temperature rating and that it’s suitable for your water type (hot/cold). This reduces the risk of seal damage or ineffective protection.

Tip: Avoid products with silicone if your seals are silicone-sensitive. - 3

Apply protector to inlet and seals

Apply a thin, even film to exposed seals, inlet fittings, and any exposed metal surfaces. Do not over-saturate; excess can cause residue and attract dirt.

Tip: Wear gloves to keep skin protected and to prevent transfer of oil to other surfaces. - 4

Distribute with a water flush

Run the pump with clean water for 20–30 seconds to distribute the protector throughout the plumbing paths. This helps avoid dry spots and ensures even coverage.

Tip: Keep the spray nozzle pointed away from you and bystanders. - 5

Wipe and inspect

Wipe away any visible excess from exterior surfaces. Check for any signs of pooling or stickiness and remove it. Inspect for leaks before returning to service.

Tip: If you see pooling, re-wipe and re-distribute the product more evenly. - 6

Store properly

Turn off the unit, allow it to cool, and store in a dry, climate-controlled area away from freezing. Label the storage date for future reference and plan the next maintenance interval.

Tip: Do a quick pre-use check next time you power up to confirm protective film remains intact.

Quick Answers

How often should I use a pump protector with my pressure washer?

Most users should apply after each use and before storage; frequency may vary by water quality and climate. Always follow the product label for your specific unit.

Apply after each use and before storage, and adjust based on water quality and climate.

Can pump protector harm my equipment?

When you choose a protector compatible with your pump and follow the label, it should be safe. Using an incompatible formula can cause seal degradation or buildup.

Use a compatible protector and follow the label to stay safe.

Should I flush water through the system before applying?

Flushing with clean water helps distribute the protector and remove residues that could react with the chemical. It’s recommended when possible.

Flush with clean water before applying if you can.

Is pump protector the same as oil for gears?

Protector formulations serve hydraulic seals and lubrication within the pump, while gear oils are for different components. Always use the product labeled for your pump type.

They’re different; check the label for your unit.

What signs suggest I need to reapply more often?

Hard water buildup, frequent use in cold climates, or following long-term storage indicate you may need more frequent reapplication.

Watch for mineral buildup and tougher starts.

How should I store my pressure washer after applying pump protector?

Store indoors in a dry area away from freezing. Run water to distribute before first use after storage and flush lines prior to reactivation.

Keep it dry, cool, and ready for use.

Watch Video

Key Takeaways

- Apply pump protector after each use and before storage.

- Choose a compatible product for your pump model and seals.

- Distribute the protector with a brief water flush to ensure coverage.

- Store properly to extend pump life and performance.