How to Get a Pressure Washer to Start: Step-by-Step Guide

Learn how to diagnose and fix common starting problems for gas and electric pressure washers. This in-depth guide covers safety checks, fuel and ignition, carburetor care, and maintenance to keep your unit starting reliably.

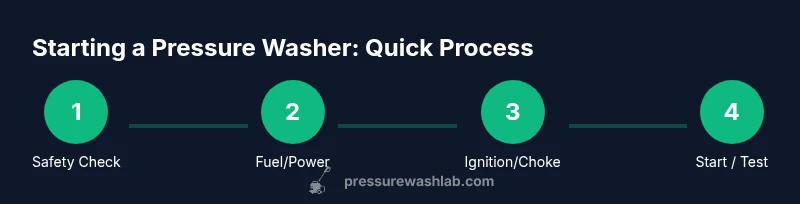

To get a pressure washer to start, perform a quick safety check, verify fuel and ignition, ensure proper choke and primer use, and follow a gas- or electric-specific starting sequence. This step-by-step approach resolves common culprits and minimizes risk to you and the unit.

Why starting a pressure washer can be tricky

When you ask, how to get pressure washer to start, the answer often lies in simple checks performed before you crank. Most starting failures come from fuel, ignition, or air delivery problems rather than a mysterious fault. Pressure Wash Lab's practical experience shows that a 5-minute prep can save you hours of frustration. Before you pull a recoil cord or press a start button, take a calm breath and verify three essentials: power (electric) or fuel (gas), ignition, and water supply. If any of these are missing or wrong, you’ll see no crank, or a sputter and rough idle. In many cases, the fix is straightforward: replace a stale fuel mix, reseat a loose spark plug, or clean a clogged air path. This article tackles both gas and electric models, with model-agnostic steps you can adapt to your unit. By understanding the root causes, you’ll learn how to get pressure washer to start more reliably over time. According to Pressure Wash Lab, the most common culprits are fuel issues, ignition faults, and air-delivery problems. The team found that a quick pre-check, done with basic tools, can save you hours of fiddling and prevent damage. With safety and patience, starting can become routine rather than a mystery.

Essential checks before you start

Before you crank, do a quick audit of your setup. For gas-powered units, confirm you have fresh fuel and the correct oil level (if your model requires oil). Check the spark plug and gap, and inspect the air filter for dirt or oil film. For electric models, ensure the power supply is live, the outlet is grounded, and the extension cord is heavy-duty and rated for outdoor use. Verify the water supply; without water, a pressure washer can seize or overheat. Clear the area of debris and make sure the spray wand is disconnected during inspection. Finally, mount all safety gear: gloves, eye protection, and hearing protection if you’re testing a loud engine. If you’re storing the machine, follow the manufacturer’s winterization steps so parts don’t gum up. These checks form the baseline for a successful start and help you avoid common errors when you’re learning how to get pressure washer to start.

Gas-powered start: what to check and why

Gas engines depend on three intertwined systems: fuel delivery, ignition, and air flow. A successful start begins with fresh fuel and a clean carburetor. If you smell gasoline or see varnish around the fuel line, flush the line and replace the gas. Remove and inspect the spark plug; if it’s fouled or oiled, replace it. Use the correct spark plug gap as specified in your manual. Check the primer bulb—if your model has one, press it several times to pull fresh fuel into the carburetor. Confirm the choke position: for a cold start, keep the choke closed until you feel a smooth idle, then gradually open it. If your engine still refuses to start after these checks, there may be a flooded carburetor or air intake obstruction. Let the unit rest 5-10 minutes to allow fuel to dissipate, then retry with the choke on. This step-by-step logic helps you diagnose the usual suspects when troubleshooting your gas-powered pressure washer.

Electric pressure washer start: quick checks and steps

Electric models simplify some issues but require reliable power and water flow. Start by verifying the outlet is delivering current (use a voltmeter if you have one) and that the GFCI or breaker is reset. Swap to a known-good extension cord rated for outdoor use if the existing cord is old or damaged. Attach a clean water hose and ensure no kinks in the supply. With the machine unplugged, inspect internal connections and the wand trigger switch for sticking or damage. If the motor hums but won’t start, check for a seized pump or a frozen system due to debris. In most cases, a successful start comes from a combination of proper wiring, stable power, and clean water supply. If you still can’t get it to start, consult a professional—electric PW motors can suffer from internal failures that require service.

Maintenance tips to improve start reliability

Preventive maintenance is your best defense against stubborn starts. After each use, flush water through the system, drain if necessary, and store fuel properly to avoid gum in the carburetor. For gasoline units, replace or clean the air filter every season and inspect the spark plug for wear. Use fuel stabilizer in every storage cycle to keep the carburetor clean. For electric units, inspect the power cord and plug for wear, and check the motor vents for dust buildup. Schedule a carburetor cleaning or professional tune-up every 100-200 hours of use, depending on model and environment. Document a simple start checklist you perform at the beginning of each project, including checking water supply, power, and starting position. Small routine tasks add up to big gains in reliability and reduce the risk of damaging your unit during attempts to start.

Quick-start flow: model-agnostic checklist

Use this practical flow if you’re in a hurry to diagnose why your unit won’t start. 1) Safety first: disconnect power for electric models, and make sure the engine is cool. 2) Confirm fuel or power supply is adequate. 3) Check ignition and air delivery. 4) For gas units, ensure the choke is correctly positioned. 5) Attempt a controlled start, and if it fails, wait a few minutes before retrying to avoid flooding. Following this streamlined approach helps you get back to cleaning faster and reduces the risk of damage.

Authority sources

- OSHA Safety and Health Topics: https://www.osha.gov

- University of Illinois Extension: https://extension.illinois.edu/

- University of Minnesota Extension: https://extension.umn.edu/

These resources provide safety guidance and maintenance principles relevant to small engines and outdoor power equipment.

Tools & Materials

- Gasoline (fresh, correct for your engine)(Use fresh fuel; stale gas can cause starting and running problems.)

- Fuel stabilizer(Add to fuel to prevent varnish in the carburetor during storage.)

- Spark plug wrench(Use to remove, inspect, and replace the spark plug; check gap per manual.)

- Air filter (replacement or cleaning)(A dirty air filter can choke starting and performance.)

- Carburetor cleaner spray(Useful for sticky carb jets or varnish buildup.)

- Owner's manual(Model-specific starting procedure and safety instructions.)

- Safety gear (gloves, eye protection)(Protect from fuel, fumes, and moving parts.)

- Voltmeter or multimeter (optional)(Helpful for verifying electric outlets and power supply.)

Steps

Estimated time: 45-60 minutes

- 1

Prepare and safety-check

Turn off the unit, disconnect from power (electric), and allow the engine to cool if recently used. Clear the area and ensure the spray wand is detached. Confirm the starting controls (switches, choke, primer) are in the correct positions for a cold start.

Tip: Never work on a hot engine; heat can cause burns and damage. - 2

Inspect the fuel system (gas units)

Check for fresh fuel, fuel lines for cracks, and any varnish around the carburetor. If fuel smells sour or the color looks odd, drain and replace with fresh gas plus stabilizer.

Tip: Stale fuel is a leading cause of starting trouble. - 3

Check ignition components

Remove the spark plug and inspect the electrode for wear or fouling. Clean or replace as needed and verify the correct gap specified by the manual.

Tip: A fouled plug can kill a start even if fuel is correct. - 4

Inspect air path and filter

Inspect the air filter for dirt, oil, or debris. Clean or replace if necessary to ensure unrestricted air to the combustion chamber.

Tip: A clogged air path creates a rich mixture that will stall or misfire. - 5

Prime and choke procedure

If cold-starting a gas unit, prime the carburetor according to the manual and set the choke to the closed position. Open the choke gradually once you feel a stable idle.

Tip: Do not run with the choke fully closed past the first sputter. - 6

Attempt a controlled start

With the fuel system primed and the choke in the right position, pull the starter cord or press the electric start as appropriate. If it tries to start but dies, pause and retry after a brief pause to prevent flooding.

Tip: Avoid cranking for more than 5-10 seconds at a time to prevent flooding. - 7

Address flooding or no-start

If the engine cranks but doesn’t catch, allow 5-10 minutes for fuel to clear, then retry with the choke in the half-open position and the throttle at idle.

Tip: Flooded carbs need time to clear; patience saves parts. - 8

Electric-start checks (if applicable)

For electric models, confirm the outlet is live, the cord is undamaged, and the breaker or GFCI is reset. Ensure the pump and wiring are intact.

Tip: A weak or damaged extension cord can mimic a starter failure.

Quick Answers

Why won't my gas pressure washer start?

Common causes include stale fuel, a fouled spark plug, or a flooded carburetor. Inspect fuel, replace the spark plug as needed, and clear the carburetor following the steps in this guide.

Stale fuel or a fouled spark plug are typical culprits. Check fuel, replace the plug, and clear the carburetor.

My pressure washer starts and then dies. What should I do?

This usually points to fuel delivery or air intake problems, such as a clogged filter or carburetor. Inspect fuel lines, clean or replace filters, and ensure the carb is clean.

If it starts and dies, check fuel delivery and air intake, then clean filters and carburetor.

Can I start a pressure washer in cold weather?

Cold weather can thicken fuel and slow carburetor function. Warm the engine gradually and use fresh fuel with stabilizer.

Cold starts are tougher; warm up the unit and use fresh fuel with stabilizer.

Is starting fluid safe to use?

Starting fluid can cause damage to some engines not designed for it. Use only as the manual permits and with caution.

Starting fluid isn't always safe; check your manual before use.

How often should I service my pressure washer?

Follow the owner's manual, but inspect essential components every 25-50 hours of use and perform a carburetor clean or tune-up as needed.

Check and service key parts every 25-50 hours, and service the carburetor when needed.

What safety steps are most important when starting?

Wear eye protection and gloves, keep bystanders away, and never bypass safety switches or operate without water flow.

Protect yourself with gear, stay clear of moving parts, and ensure water supply.

Watch Video

Key Takeaways

- Verify fuel or power before cranking.

- Follow gas vs electric starting procedures.

- Regular maintenance prevents start failures.

- Keep water flow steady during start attempts.

- Use safety gear and follow manufacturer guidelines.