How to Make Soap Come Out of a Pressure Washer

Learn practical, field-tested steps to deliver soap from your pressure washer with the right detergent, injector, and technique. Includes setup, dilution tips, troubleshooting, and safety guidance from Pressure Wash Lab.

To make soap exit your pressure washer, attach a detergent injector or soap nozzle, connect a compatible detergent reservoir, and run at low pressure with a wide spray. Use a light dilution, verify the soap is designed for pressure washers, and keep the wand moving to prevent streaks and buildup.

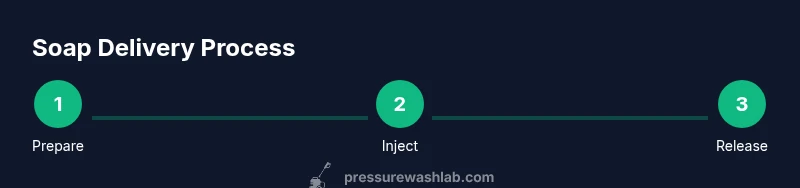

How soap delivery works in a pressure washer

Soap delivery in a pressure washer hinges on a simple principle: the machine injects or siphons detergent from a reservoir into the high-velocity water stream. When you enable a detergent system, the soap is drawn into the spray stream downstream of the pump. The result is a foamy, even coat that helps lift dirt before you rinse. According to Pressure Wash Lab, using a purpose-built detergent and a proper injector minimizes air pockets, reduces clogs, and ensures consistent distribution across the surface. This is especially important when tackling tough stains on driveways or siding, where inconsistent application can waste soap and leave streaks. Understanding how your system handles dilution, nozzle type, and flow rate helps you optimize coverage while protecting seals and hoses from unnecessary exposure to harsh cleaners. As you gain experience, you’ll learn to switch between soap and rinse modes with minimal downtime, preserving both your time and your equipment.

Detergents and compatibility

Not all soaps are created equal for pressure washers. Use detergents specifically formulated for pressure washing, and avoid household cleaners that can generate excessive suds, corrode seals, or leave residues that require extra rinsing. Detergents designed for pressure washers often include surfactants that improve wetting, chemistry tailored to outdoor soils, and viscosity that prevents immediate dripping from the nozzle. Always check the label for dilution ranges and compatibility with your machine’s pump type and nozzle. Pressure Wash Lab notes that using a too-thick or incompatible chemical can clog the injector, reduce flow, and shorten the pump’s life. When in doubt, run a small test on an inconspicuous area and observe how the foam, cling, and rinsing behave. Remember that different surfaces—wood, concrete, painted metal—may require different detergents or dilution ratios to avoid damage.

Equipment you need for soap output

A reliable detergent setup usually includes a dedicated detergent reservoir, a compatible injector or soap nozzle, a wand, and a low-pressure setting. If your machine lacks a built-in soap system, you can attach an external injector kit or use a foaming nozzle designed for detergents. Detergent containers should be formulated for pressure washers and labeled for the appropriate dilution. A clean funnel and a measuring cup help with accurate mixing. Keep spare hoses and seals on hand, as detergents can accelerate wear on certain gaskets if used improperly. Proper storage of soap and equipment reduces the risk of accidental mixing with incompatible cleaners and makes cleaning up quick after the job is complete.

Step-by-step setup for soap output

Set up the detergent reservoir and injector in a clean, dry area. Ensure the pressure washer is off, water supply is secured, and the machine is on level ground. Prime the system by running water through the injector to remove air, then fill the reservoir with the recommended detergent dilution. Attach the injector or soap nozzle to the spray wand and verify tight connections. Test on a spare surface with the nozzle on a wide spray to confirm the soap is drawing and dispensing. If you don’t see foam, pause and re-check the connections, and confirm the detergent label’s dilution range. Finally, move the wand slowly and methodically across the surface to ensure even coverage without overspray.

Techniques for even soaping and avoiding streaks

To achieve even coverage, start with a pre-wet on the surface, then apply soap in a steady, overlapping pattern. Use a wide spray for initial application, gradually narrowing to target areas as needed. Keep the wand moving to prevent pooling that can darken or warp finishes. If streaks appear, readjust the nozzle to a slightly wider angle or increase dilution slightly; better coverage often comes from consistent motion rather than forceful spraying. Rinse briefly after soap application to remove excess suds and reveal the cleaning progress.

Troubleshooting common problems with soap delivery

If soap isn’t dispensing, check that the reservoir is filled, the injector is properly seated, and there are no kinks in the supply hose. Air pockets in the line can prevent suction; re-prime the system by flushing water through the injector until full. If the detergent foams excessively or clogs the line, confirm you’re using a product designed for your model and that the dilution isn’t too thick for the injector. For stubborn residues or moldy surfaces, switch to a higher-dilution, lower-foam formula and re-test on a small area. Finally, inspect seals and o-rings for wear that could allow air ingress or leaks, which disrupt the soap flow.

Tools & Materials

- Pressure washer with detergent injector compatibility(Ensure your model supports a detergent system or external injector kit)

- Detergent formulated for pressure washers(Avoid household cleaners and high-foaming products unless specified)

- Detergent reservoir or siphon hose(Use a reservoir that fits your injector and remains stable during motion)

- Soap nozzle or detergent injector(Choose a nozzle with a wide spray angle for even coverage)

- Measuring cup or dilution bottle(Helpful for accurate dilution and repeatable results)

- Protective eyewear and gloves(Prevent chemical splash and skin exposure)

Steps

Estimated time: Total time: 20-30 minutes

- 1

Prepare the workspace and equipment

Place the washer on a stable surface, connect the water supply, and verify the area is clear. This prevents slips and ensures the machine will prime correctly. A clean area also reduces contamination of detergents and makes cleanup easier.

Tip: If possible, perform a quick dry run with water only to confirm there are no leaks. - 2

Attach detergent reservoir and injector

Mount the reservoir securely and connect the injector hose to the wand. Tighten fittings to avoid leaks. Proper attachment prevents air ingress, which can stop soap from drawing.

Tip: Use thread sealant only on metal fittings if recommended by the manufacturer. - 3

Dilute and load detergent

Follow the detergent label for dilution and pour into the reservoir. A consistent dilution ensures foam quality and cleaning effectiveness without leaving residues.

Tip: Label the bottle with the mix ratio for quick reference on future jobs. - 4

Prime the system and test spray

Run water through the injector to remove air, then test on a non-sensitive surface. If you don’t see any soap, recheck connections or adjust the injector settings.

Tip: Test on concrete or an inconspicuous area before broader application. - 5

Apply soap with correct nozzle

Switch to a low-pressure setting and use a wide spray angle to apply soap evenly. Maintain a steady pace and overlap strokes to avoid gaps.

Tip: Avoid saturating delicate surfaces; short, controlled passes work best. - 6

Rinse and assess

After cleaning with soap, switch back to rinse mode and remove all soap remnants. Inspect the surface for remaining stains and reapply if necessary.

Tip: Always finish with a thorough rinse to prevent soap residue and streaks. - 7

Shut down and store properly

Turn off the machine, depressurize the system, and disconnect hoses. Clean the reservoir and nozzle to prevent chemical buildup that can impair future use.

Tip: Store detergents upright and away from heat sources.

Quick Answers

Can I use any soap in a pressure washer?

Not all soaps are suitable for pressure washers. Use detergents labeled for pressure washers to avoid damage to seals and pumps. Check the product guidelines and perform a small test on an inconspicuous area.

Not all soaps are suitable for pressure washers. Use detergents labeled for pressure washers and test on a small area first.

What dilution should I use for soap output?

Follow the detergent label for the recommended dilution. Start with a light mix and adjust based on cleanliness and surface type. Overly thick mixtures can clog the injector and leave residues.

Follow the detergent label for dilution and start light, adjusting as needed.

Do I need a detergent injector?

An injector or soap nozzle dramatically improves soap delivery and coverage. If your model lacks it, you can use a compatible external kit, but results may vary.

An injector or soap nozzle greatly helps with coverage; if unavailable, a compatible external kit can work.

Can I run soap without a dedicated nozzle?

You can, but it often leads to uneven coverage or foaming. A dedicated nozzle or injector helps control flow and spray pattern for consistent results.

Without a dedicated nozzle, coverage may be uneven; a proper injector improves results.

What safety precautions should I take?

Wear eye protection and gloves, avoid electrical hazards, and never mix chemicals. Keep children and pets away while spraying, and follow manufacturer safety guidelines for your machine.

Wear eye protection, keep kids away, and follow all safety guidelines when using detergents.

Watch Video

Key Takeaways

- Use a detergent system designed for pressure washers.

- Dilute soap correctly and apply evenly with a wide spray.

- Prime, test, and rinse to avoid streaks and residue.

- Safety first: eye protection, gloves, and proper storage.