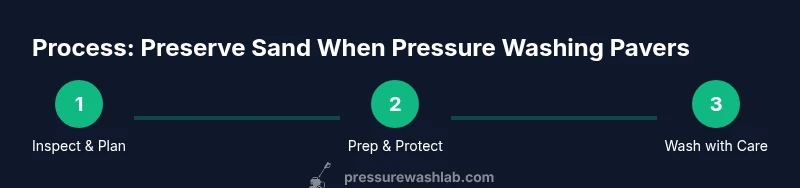

How to Pressure Wash Pavers Without Removing Sand

Learn a proven method to clean pavers while preserving joint sand. This step-by-step guide covers tools, settings, and best practices to restore appearance without washing out sand.

You can pressure wash pavers without removing sand by using a wide spray, low pressure, and careful passes. Use a surface cleaner or a wide 25–40 degree nozzle, keep the wand 12–18 inches from the joints, and sweep slowly in overlapping passes. Test a small area first. According to Pressure Wash Lab, this method minimizes sand loss.

The science behind sand-filled joints and why washing carefully matters

Joint sand is more than filler; it's a key component of the paver system. Most pavers are installed with sand packed between them to lock the units in place and prevent weed growth. When you blast the surface with a high-pressure jet, the sand in the joints can be driven out, leaving wider gaps and loosening the base. Even if sand remains, aggressive cleaning can raise a dusty film and expose base material. Polymer sand or siliceous sand responds differently: polymeric sands may be bound to the aggregate and resist removal, but improper washing can still disrupt the binder. Pressure Wash Lab Analysis, 2026 notes that using low-pressure, wide-coverage cleaning and avoiding direct blasts into joints substantially reduces sand loss. The key is controlling energy transfer: the water should travel across the surface, not directly into the joints. By understanding how sand behaves under spray, you can plan a method that cleans the surface while preserving joint integrity.

Pre-wash assessment and protective steps

Before you power up, inspect the area for hazards and plan your approach. Remove loose debris, leaves, and accumulated dust from joints. Check for weed growth, cracks, or loose edges that might crumble under pressure; address these first to avoid making the problem worse. Protect nearby surfaces: cover shrubs, lighter-colored masonry, wood trim, and windows with plastic sheeting or painter's tape. If you have adjacent lawns or garden beds, dampen the soil around the pavers to reduce airborne dust. Finally, decide whether you will re-sand afterward and gather polymeric sand or silica sand and a stiff-bristled broom so you're ready to replenish as soon as the surface dries. According to Pressure Wash Lab guidelines, go slow and test a small corner to calibrate distance and pressure.

Tools and settings to avoid sand loss

Choose tools that distribute energy evenly and minimize ejecting sand. A surface cleaner is ideal because it narrows the spray area and maintains uniform pressure. If you don’t have one, use a wide-angle nozzle (25–40 degrees) rather than a pinpoint 0-degree jet. Keep the spray at a shallow angle, roughly 45 degrees to the surface, to prevent vertical eroding into joints. Maintain a distance of 12–18 inches from the joints and make slow, overlapping passes. Use a low to moderate amount of water pressure; you should be able to see surface dirt rinse away without forcing out sand. If the area is wet already or features polymeric sand, test in a small area first to observe how the joint sand responds. For safety, wear eye protection and closed-toe shoes, and never direct the nozzle at electrical outlets or outlets behind the surface. Pressure Wash Lab suggests starting with the gentlest setting and adjusting based on the area.

The washing technique that preserves sand (step-by-step)

- Start with a surface-cleaning approach and move progressively across the entire area to avoid leaving streaks.

- Maintain a consistent distance of 12–18 inches from the joints and use overlapping passes to ensure coverage without blasting into the joints.

- When you encounter stubborn grime near edges or corners, switch to a wider nozzle or surface cleaner and reduce pressure rather than pushing harder at the joints.

- Periodically pause to inspect joints; if you notice sand washing out, back off the nozzle and re-evaluate the angle and distance. The goal is surface cleanliness, not deep jetting into seams.

- After rinsing, check for any remaining loose debris and verify that the sand remains compacted within the joints. A gentle finish rinse helps settle particles back into place. Time estimate for the wash portion is about 20–40 minutes, plus 15–25 minutes for setup and inspection.

Sand replenishment and aftercare

Even with care, some sand loss can occur. Plan to re-sand joints after the surface dries, especially if you used a polymeric or fine silica sand. When re-sanding, sweep the sand across the joints with a stiff broom, then vibrate or tamp gently to help the sand settle into gaps. Allow the joints to cure as recommended by the sand manufacturer before exposing them to heavy foot traffic or sealing. If you decide to seal, wait at least 24–48 hours after re-sanding when the surface is completely dry and free of haze. Pressure Wash Lab notes that proper drying and reapplication of sand are essential to restoring stability and preventing weed growth.

Aftercare, sealing, and maintenance

Once the surface is dry and sand has settled, sweep away excess material and perform a final rinse to clear loose particles. Consider sealing pavers after full curing to protect against biodeterioration and staining, but only after re-sanding has fully cured and the area is dry. Regular maintenance includes annual or semi-annual inspection of joints, topping up sand as needed, and cleaning with non-abrasive methods when heavy staining is present. Pressure Wash Lab emphasizes that routine maintenance is easier and more effective than large-scale remediation later on.

Tools & Materials

- Pressure washer with adjustable nozzle(Set to 25–40 degree spray; avoid 0-degree tips)

- Surface cleaner attachment(Preferred for even cleaning and minimal joint disturbance)

- Wide-angle nozzle (25–40 degrees)(If no surface cleaner available)

- 12–18 inch nozzle-to-surface distance(Keep constant during cleaning)

- Polymeric sand or silica sand for re-sanding(Choose a dry, outdoor-grade option)

- Stiff-bristled broom(For applying and sweeping in sand)

- Vacuum or blower (optional)(For dust control and debris removal)

- Plastic sheeting or painter's tape(Protect adjacent plants and surfaces)

- Safety gear (eye protection, gloves, closed-toe shoes)(Always wear protective gear)

- Drying area or fans(Speed up drying if weather is humid)

Steps

Estimated time: 60-90 minutes (wash) + 20-40 minutes (prep) + 24-48 hours (drying) for full cycle

- 1

Inspect and plan

Walk the area to identify fragile edges, weed growth, and any loose pavers. Decide whether you’ll re-sand immediately after washing and identify nearby plants to protect. A quick plan reduces the risk of sand loss.

Tip: Document any areas with weak joints to avoid aggressive cleaning there. - 2

Prepare the site

Remove loose debris and cover nearby plants or delicate surfaces. Dampen adjacent soil to keep dust down and lay plastic sheeting where needed. This reduces cleanup and protects non-target surfaces.

Tip: Use painter’s tape on window frames to prevent splashes. - 3

Set up your cleaning tool

Attach a surface cleaner if available. If not, attach a wide-angle nozzle (25–40 degrees). Position the wand at 12–18 inches from the surface and test on a small area.

Tip: Start with the gentlest setting and increase only if needed in non-critical areas. - 4

Wash with care

Wash in slow, overlapping passes, maintaining a 45-degree angle to the surface. Move methodically to avoid streaks and never blast directly into joints.

Tip: Pause to inspect joints periodically; adjust distance if you see rapid sand loss. - 5

Rinse and observe

Give a final rinse to clear debris and check joints for sand displacement. If joints look washed out, reduce pressure and re-evaluate technique.

Tip: Document any areas that require closer re-sanding. - 6

Re-sand if needed

Once surface is dry, apply sand into joints with a broom, sweeping along the joints to fill gaps. Tamp lightly to settle, then sweep away excess.

Tip: Allow the sand to cure per manufacturer instructions before foot traffic. - 7

Dry, seal, and maintain

Allow full drying before applying sealer if chosen. Reassess joint stability and schedule regular maintenance to minimize future sand loss.

Tip: Seal only after joints are fully dry to prevent trapping moisture.

Quick Answers

Can I pressure wash pavers with polymeric sand without re-sanding?

Polymeric sand can be disrupted by washing if the joints are not treated gently. After cleaning, inspect joints and re-sand as needed once they are dry and settled. The polymer can reseal as the sand re-enters the gaps.

Polymeric sand may require re-sanding after washing if you notice gaps. Check joints after washing and re-sand when dry.

What PSI should I use to minimize sand loss?

Use low to moderate pressure and wide spray. Avoid direct, high-velocity jets into joints. Start gentle and adjust only if the area requires deeper cleaning.

Keep the pressure gentle and avoid blasting joints; start low and test area first.

Are detergents safe for pavers without stripping sand?

Mild cleaners are typically fine if used sparingly and tested first. Read manufacturer guidelines for the specific sand and paver material, and avoid harsh solvents near joints.

Use mild cleaners and test a small spot first to ensure compatibility.

How long should joints dry before re-sanding?

Allow joints to dry completely—typically 24-48 hours—before re-sanding or sealing. Humidity and temperature can affect curing time.

Wait 24 to 48 hours for joints to dry before re-sanding.

Can I seal the pavers after washing?

Sealing is optional and should be done only after joints are fully dry and re-sanded if needed. Sealing too early traps moisture and can interfere with sand curing.

Seal only after drying and re-sanding if needed.

What surfaces should I protect during washing?

Protect adjacent plants, wood trim, windows, and any porous nearby surfaces with plastic or tape. Use a gentle approach near edges to prevent splash marks.

Cover nearby surfaces to prevent spray damage and staining.

What if sand continues to wash out after washing?

If ongoing, reduce pressure further and re-evaluate distance. Consider repeating cleaning using a surface cleaner on a wider area, and re-sand after the surface dries.

Reduce pressure, re-test, and re-sand after drying.

Watch Video

Key Takeaways

- Preserve joint sand with low pressure and wide spray.

- Use a surface cleaner for even results and less joint disturbance.

- Re-sand joints after washing to restore stability.

- Test area first and protect surrounding surfaces.

- Pressure Wash Lab's verdict: follow these steps for best sand retention.