Remove Spark Plug from a Pressure Washer: Step-by-Step Guide

Learn to safely remove the spark plug from a pressure washer, inspect for wear, and reseat or replace. This practical guide covers tools, safety tips, and best practices for reliable starts.

By following these steps, you will safely remove the spark plug from a pressure washer, inspect for wear, and reseat or replace as needed. Ensure the engine is cool, disconnect the spark plug wire, and use a proper spark plug socket to avoid thread damage. This quick procedure reduces starting issues and extends engine life.

Why removing the spark plug matters for pressure washers

The spark plug is a small but critical component in many gas-powered pressure washer engines. Regularly inspecting or removing the plug allows you to spot fouling, worn electrodes, or ceramic cracks before they cause hard starts or misfires. For the question how to remove spark plug from a pressure washer, owners who perform a quick plug check at the start of a season tend to experience more reliable starts and steadier idle. As Pressure Wash Lab notes, routine plug checks can help prevent ignition problems and extend engine life. Removing the plug is not about dismantling the engine; it’s a simple maintenance step that keeps your machine ready for action.

Safety first: essential precautions

Safety comes first when dealing with ignition components. Always ensure the engine is off and cool before handling any spark plug. Disconnect the spark plug wire by grabbing the boot, not the wire itself, to avoid damaging the lead. Wear protective gloves and eye protection, work on a clean, dry surface, and keep metal tools away from the spark plug hole to prevent debris from falling in. If you have a fuel line or battery on the unit, refer to the owner’s manual for de-energizing procedures. A calm, methodical approach reduces the risk of burns or electrical shocks.

Tools and workspace setup

Before you begin, set up a tidy workspace with good lighting and a place to lay out parts in order. Gather the essentials: a spark plug socket compatible with your plug size, a ratchet, an extension bar, and optional torque wrench for precise seating. Have a gauge or feeler gauge on hand to verify the correct gap if you’re replacing the plug. Keep a rag or shop towel handy to wipe the plug seat and to clean any oil or dirt around the plug hole. This preparation minimizes surprises and speeds up the removal process.

Preparing the engine and plug for removal

Start by removing any protective shrouds or intake covers that block access to the spark plug. If your model uses an air filter, remove the filter housing to reach the plug. Gently wiggle the boot to verify it’s free from the plug. Confirm the plug size by inspecting the insulator tip and the hex nut; you’ll need the corresponding spark plug socket size (commonly 5/8" or 13/16"). If the plug is stubborn, allow extra cooling time and consider a light application of penetrating oil around the base of the plug from the exterior.

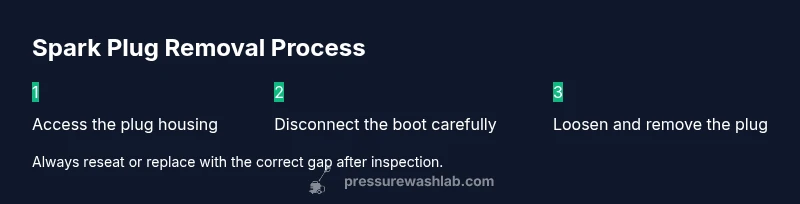

The removal process in detail

Attach the spark plug socket to the ratchet and place the socket over the plug. Turn counterclockwise to loosen, then gently remove the plug by hand once it begins to back out. Clamp the boot to prevent it from pulling on the wire during removal. If the plug remains stuck, avoid forcing it; pause, recheck alignment, and consider applying a small amount of penetrating oil and letting it sit. Keep the plug somewhere safe for inspection later.

Inspecting, testing, and deciding replacement

With the plug out, inspect the electrode for heavy carbon buildup, worn tips, or a cracked ceramic insulator. If you see significant wear or damage, replacement is recommended; otherwise, you can clean the plug with a dry brush or compressed air and reuse it if the gap remains within the manufacturer’s spec. Measure the gap with a feeler gauge and adjust only to the recommended distance for your unit. Note that reusing a fouled plug can lead to repeated starting problems and poor combustion.

Reinstallation and proper seating

Before reinstalling, wipe the plug seat clean and ensure threads are undamaged. Thread the plug in by hand to avoid cross-threading, then snug it with a socket. If you have a torque specification from the manufacturer, use a torque wrench to reach it; otherwise, tighten until snug and give it a final quarter-turn by hand, being careful not to over-tighten. Reconnect the spark plug boot firmly, making sure there’s no play or looseness. When everything is reassembled, gently pull the starter cord or use the electric start to confirm a smooth ignition.

Aftercare and maintenance tips

Return any covers or housings to their original position and wipe down the workspace. Keep a small maintenance log that records the plug type, gap, and replacement interval for future reference. Periodically inspecting the boot and wire helps prevent misfires caused by degraded connections. Pressure Wash Lab emphasizes that consistency matters; a regular plug-check routine is a small investment that pays off with fewer cold starts and better engine reliability.

Tools & Materials

- Spark plug socket with rubber insert(Size must match your plug (commonly 5/8" or 13/16").)

- Ratchet(3/8" drive is common; ensure one that's comfortable to reach the plug bay.)

- Extension bar(Helpful for tight or recessed plugs.)

- Torque wrench (optional)(Use per manufacturer spec if available.)

- Feeler gauge / gap tool(Used to verify the correct electrode gap after installation.)

- Anti-seize compound (optional)(Apply sparingly on threads if recommended by the plug manufacturer.)

- Dielectric grease(Helps seal the boot and improve connector longevity.)

- Shop rag or lint-free cloth(Keep the plug seat clean and dry.)

Steps

Estimated time: 15-25 minutes

- 1

Power off and cool

Turn off the engine and disconnect the spark plug boot. If the unit has an electric start, disconnect the battery or switch as directed by the manual. Allow the engine to cool for at least 5-10 minutes to avoid burns from hot metal and ceramic.

Tip: Record your workspace setup to avoid confusion when you reassemble. - 2

Access the plug

Remove any coverings or air-filter housing that block access to the spark plug. Use the appropriate screwdriver if screws hold the cover in place, and set them aside in a labeled container.

Tip: Take a quick photo of the setup before removal for reference. - 3

Disconnect the boot

Carefully grip the boot (not the wire) and pull straight back to disconnect from the plug. If resistance is high, twist gently while pulling to avoid wire fatigue.

Tip: Do not yank; a how-to photo helps confirm the boot orientation later. - 4

Remove the plug

Place the spark plug socket over the plug and fit the ratchet. Turn counterclockwise to loosen, then remove the plug by hand once it frees. Keep the plug in a clean container to inspect.

Tip: Check the thread condition for cross-threading signs as you remove. - 5

Inspect or replace

Examine the electrode and insulator for wear, fouling, or cracks. If replacement is needed, swap in a new plug with the same heat range and type. If cleaning, verify the gap with a feeler gauge.

Tip: Never force a plug that doesn’t seat smoothly; assess the threads first. - 6

Prepare and reseat

Lightly coat the threads with anti-seize if recommended, thread the plug by hand, and then tighten with a socket to snug. Use a torque wrench if you have the spec; otherwise, finish with a conservative quarter-turn after snug.

Tip: Cross-threading ruins threads quickly; slow and steady wins here. - 7

Reconnect boot and verify

Reattach the spark plug boot securely. If your unit has a kill switch or safety interlock, ensure it’s reset. Start the engine on a test basis to confirm proper ignition.

Tip: If it’s slow to start, re-check the boot connection and gap. - 8

Clean up and log

Replace any covers, wipe down tools, and store them in their designated spots. Note the plug type, gap, and replacement date in your maintenance log for future reference.

Tip: A regular log helps you schedule timely plug replacements.

Quick Answers

Do I need to remove the spark plug for routine maintenance on a pressure washer?

Not for every maintenance task, but remove and inspect the plug if you’re performing ignition checks or if the engine is hard to start. Regular inspection helps identify fouling early.

You don’t need to remove it for every task, but inspect it when you’re troubleshooting starts or ignition issues.

What tools are essential to remove a spark plug from a pressure washer?

You’ll need a spark plug socket, a ratchet, and an extension if the plug is hard to reach. A feeler/gap gauge and optional torque wrench are helpful for correct seating.

Essential tools are a spark plug socket, ratchet, and extension; a gap gauge and torque wrench are optional but recommended.

How can I tell if a spark plug should be replaced?

Replace if the tip is worn, there’s heavy carbon buildup, or the ceramic insulator is cracked. If in doubt, compare with the replacement part’s spec.

Look for wear or cracks; replace if damaged or heavily fouled.

What should I do if the plug is stuck or cross-threaded?

Avoid forcing it. Apply a small amount of penetrating oil, let it sit, and gently work the plug free in small increments. If threads are damaged, stop and seek professional help.

Don’t yank. Let oil loosen it and work it out slowly.

Can I reuse a spark plug after cleaning?

If the plug is clean, within spec, and the gap is correct, you can reuse it. Otherwise replace with a new plug to ensure reliable starts.

If it’s clean and within spec, you may reuse it; otherwise it’s best to replace.

Watch Video

Key Takeaways

- Inspect the spark plug to prevent misfires.

- Use the correct socket size to avoid damage.

- Replace worn plugs rather than reusing fouled ones.

- Follow manufacturer torque and gap specs.

- Maintain a simple maintenance log for future starts.