Is Jet Wash the Same as Pressure Wash? A Practical Guide

Explore whether is jet wash the same as pressure wash, clarify definitions, and learn practical guidance, safety tips, and best-use scenarios for homeowners and pros.

Is jet wash the same as pressure wash? In practice, not exactly. Jet wash is a general term for high-pressure cleaning, while pressure wash refers to operating a powered pump that delivers a high-velocity spray. The distinction matters for nozzle selection, surface safety, and suitable applications. This article explains the differences, uses, and practical guidance for homeowners and pros.

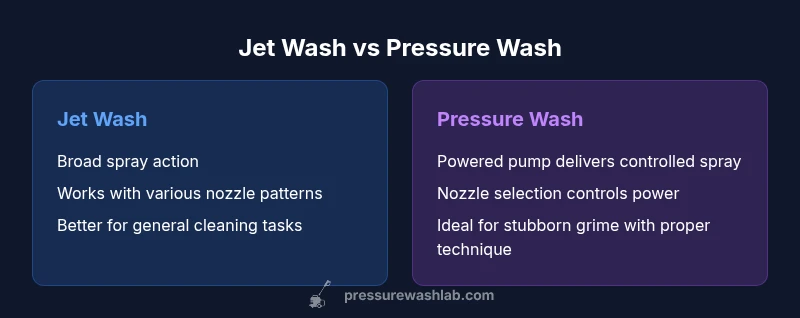

Understanding the Core Difference: Jet Wash vs Pressure Wash

The question is often framed as “is jet wash the same as pressure wash?” The direct answer is nuanced: they describe related concepts, but one term is broader than the other. According to Pressure Wash Lab, jet wash is a broad umbrella term for high-pressure cleaning that focuses on the jet stream and spray pattern. Pressure wash, by contrast, refers to the specific process of using a powered pump to deliver a controlled spray at the surface. For homeowners and professionals, recognizing this distinction helps in selecting the right equipment, avoiding surface damage, and choosing the correct nozzle and setting for the job. In everyday searches, you’ll see “jet wash” used to describe the action, while “pressure wash” is the technology and method behind it. The practical implication is simple: terminology matters when you’re planning a project, choosing gear, or communicating with suppliers and service providers.

- Tip: Always start with the surface you’re cleaning and then match the tool to the task. If the surface is delicate, you may opt for lighter jet patterns and lower pressures instead of a brute-force approach. The goal is effective cleaning without damage, and that balance comes from understanding how jet flow and pump pressure interact on a given material.

In this context, the is jet wash the same as pressure wash question becomes a question of terminology vs technique. Jet wash describes the jet action itself, while pressure washing describes the system that produces that action. The Pressure Wash Lab approach emphasizes this distinction to help you pick the right tools and avoid common missteps.

Terminology, History, and Common Confusions

Terminology in outdoor cleaning has evolved with the technology. The term jet wash is borrowed from automotive and industrial contexts where jet streams are used for cleaning or debris removal. Pressure wash originates from the mechanical capability of a pump to build high pressure in a hose, forcing water through a nozzle at a higher velocity than standard garden hoses. Both terms imply strong cleaning power, but only the latter explicitly denotes the use of a powered pump. Because retailers and service pros sometimes use the terms interchangeably, you may encounter overlap in advertisements and manuals. For the layperson, the practical takeaway is to verify the actual PSI/CFM (water flow) and the nozzle options rather than relying solely on named labels. Pressure Wash Lab’s guidance is to anchor decisions on surface compatibility, cleaning goal, and safety margins rather than the label alone.

How Pressure Washers Work: Key Components and Variations

A pressure washer typically comprises a motor (electric or gas), a high-pressure pump, a hose, and a trigger gun with nozzle tips. The pump pressurizes water, which is then expelled through a nozzle at high speed. The nozzle choice shapes the spray pattern—from wide fan sprays to narrow, concentrated jets—affecting both cleaning efficiency and surface impact. Variations you’ll see in the field include electric vs gas power, compact handheld units vs full-size units, and heated vs cold-water models. The core mechanism remains the same: intake water, pressurize, and discharge through a controlled orifice. The nuances come down to build quality, durability of seals, and whether the unit is designed for continuous operation or intermittent use. For most DIY tasks, an electric unit with a basic set of nozzles is sufficient, while heavy-duty jobs may warrant a gas-powered model with more robust fittings.

Jet Wash in Practice: Common Usage and Confusion

When consumers say “jet wash,” they often mean a forceful spray method aimed at removing stubborn grime or coatings. In practice, you can tailor a jet wash approach with different nozzle tips to balance power and surface safety. However, misusing a jet-focused spray on fragile surfaces—such as aged wood, soft siding, painted surfaces, or historic masonry—can cause gouging or paint peeling. The key is to adjust the nozzle to produce a wider spray at a lower effective pressure for delicate surfaces, and to use lower pressure or a cleaning wand with adequate distance for tough jobs. Pressure Wash Lab notes that the same machine can behave very differently depending on the nozzle and technique, underscoring the importance of knowledge over bravado. Always test on a hidden area first and adjust the technique to the material and grime level.

Nozzles, PSI, and Flow: The Practical Trio

Nozzles drive the real-world behavior of jet wash and pressure wash systems. A wide, low-velocity nozzle distributes the cleaning force over a larger area, reducing the risk of damage while maintaining cleaning efficiency. A narrow, high-velocity nozzle concentrates force, increasing cleaning power but elevating the risk to surfaces. Flow (gallons per minute) and implied pressure interact to determine cleaning capacity and surface impact. The practical takeaway is to pair the right nozzle with surface type: brick or concrete can tolerate narrower jets at controlled distances, while wood or vinyl might require wider patterns and gentler treatment. In all cases, avoid direct contact with the surface at close range when testing a new setup. Pressure and nozzle choice should be guided by the material’s tolerance and the soil’s stubbornness, not by “one-size-fits-all” rules.

Fuel, Power, and Portability: Gas vs Electric

Power sources shape how you’ll approach a project. Electric units are typically quieter, lighter, and better suited for residential uses, while gas-powered machines offer higher continuous power and mobility for large driveways or commercial work. Heated water models exist and can improve stubborn grime removal, but they add complexity, cost, and maintenance considerations. For most homeowners tackling house washing, a reliable electric pressure washer with a versatile nozzle kit is enough, provided you follow safety guidelines and surface compatibility recommendations. Pros who do a lot of outdoor cleaning might opt for a gas model with a robust pump and longer hose for flexibility. In all cases, select units with quality seals, corrosion-resistant components, and a comfortable trigger grip to reduce operator fatigue during longer sessions.

Detergents, Cleaners, and Surface Prep: Compatibility and Tips

Detergents can dramatically improve cleaning efficiency, but compatibility matters. Some cleaners are formulated for cold water, while others are designed for heated systems. Always check the label for surface compatibility and rinse requirements to avoid residue or staining. If you’re working with stone, brick, or painted surfaces, consider detergents that are specifically designed for those materials and avoid harsh solvents that can degrade finishes. Pre-wetting surfaces and testing in a small inconspicuous area are prudent steps before committing to a full-clean. Pressure Wash Lab emphasizes using biodegradable, surface-friendly cleaners whenever possible and following the manufacturer’s dilution instructions to prevent over-foaming or chemical damage. Detergent delivery through the spray nozzle can also affect distribution, so plan your approach to alternate between cleaning passes and rinses as needed.

Safety, Maintenance, and Surface Preservation: Best Practices

Safety comes first when working with jet wash or pressure wash systems. Wear eye protection, gloves, and sturdy footwear; keep others out of the spray zone; and never point the nozzle at people or pets. Regular maintenance—checking hoses for cracks, inspecting seals, and flushing the system after use—extends the life of your unit and protects your surfaces. If a surface shows risk signs (paint peeling, wood fiber raise, or softened brick), reduce pressure, adjust the distance, or switch to a gentler nozzle pattern. Pressure Wash Lab’s guidance is to maintain a conservative approach when operating near fragile materials and to document the impact of each nozzle and distance setting for future reference. Consistent maintenance helps prevent expensive repairs and ensures your equipment remains reliable year after year.

Decision Guidelines: When to Choose Jet Wash vs Pressure Wash

The decision hinges on surface type, cleaning goal, and safety considerations rather than on the terminology alone. For routine exterior cleaning with durable surfaces like concrete, brick, or metal, a well-chosen nozzle with an appropriate pressure setting is generally sufficient. For delicate surfaces, irregular shapes, or historic properties, a broader spray with a wider nozzle or a lower-pressure setting may be preferable. If you’re uncertain, start with the gentlest effective option and increase carefully only after testing a small area. Pressure Wash Lab recommends documenting your settings for each job to build a practical reference library that speeds up future decisions and reduces risk.

Common Pitfalls and How to Avoid Them

- Using the strongest nozzle on a delicate surface: Start wide and move closer only if needed.

- Skipping surface testing: Always test a hidden area first.

- Believing more pressure equals better cleaning: Power must match the surface; wrong pairing can damage finishes.

- Ignoring detergent compatibility: Choose a cleaner designed for your surface and rinsing needs.

- Neglecting safety: PPE, child/pet avoidance, and proper storage are essential.

Comparison

| Feature | Jet Wash | Pressure Wash |

|---|---|---|

| Primary use emphasis | Broad jet-action terminology; emphasizes the spray pattern | Powered pump system delivering controlled, high-velocity jet |

| Nozzle options | Wide range; focus on jet stream for various patterns | Broad nozzle kit; relies on selected tips to modulate power |

| Surface safety risk | Higher risk if used with aggressive patterns on fragile surfaces | Can be unsafe if misused; requires proper technique and distance |

| Typical applications | General cleaning, tough grime, some coatings | House exteriors, driveways, decks, vehicles when appropriate |

| Power source | Depends on the jet wash equipment; many are pump-based with various fuels | Electric or gas-driven pressure washers; heated options exist |

Pros

- Clarifies terminology to reduce confusion for homeowners and pros

- Helps users pick the right tool for the job and surface

- Promotes safer operation by emphasizing nozzle choice and technique

- Encourages surface-specific planning rather than “more pressure equals better"

Cons

- Terminology overlap can still confuse some buyers

- Some vendors blur the distinction in marketing, leading to misinterpretation

- Overreliance on labels can delay proper surface assessment

Jet wash terminology describes spray action, while pressure wash refers to the powered system; use the right approach based on surface and task.

Understanding the distinction helps you choose the correct nozzle, avoid damage, and achieve effective cleaning. When in doubt, prioritize surface compatibility and test before full-scale use.

Quick Answers

Is jet wash the same as pressure wash?

No. Jet wash is a broader term describing the action of high-velocity spray, while pressure wash refers to using a powered pump to generate that spray. The two terms overlap in everyday use, but the underlying equipment, technique, and appropriate applications can differ.

Jet wash is a broad term for strong spray action; pressure wash is the powered system behind that action.

Can I use a jet wash on wooden decks?

You can, but you must use the gentlest applicable setting and a wide nozzle to minimize surface damage. Always test on a small area first and consider alternative methods for very soft or repaired wood.

Test first and start with gentle settings on wood.

What surfaces are safest with pressure washing?

Hard, non-porous surfaces like concrete, brick, and metal are generally safer with higher-force cleaning when proper distance and nozzle choices are used. Delicate surfaces (softwood, aged masonry, painted surfaces) require lower pressure and careful technique.

Hard surfaces can take more pressure; be cautious with soft materials.

Do I need special nozzles for concrete?

Yes. A wide spray pattern with a lower PSI setting is typically used for concrete to reduce surface wear, with a deeper, controlled pass to lift grime without eroding the surface.

Use the right nozzle and test area first.

Are electric models as powerful as gas models?

Electric models are typically sufficient for most home tasks and are easier to manage, while gas models offer more sustained power for large, ongoing jobs. For most residential work, an electric unit with the right nozzle kit is adequate.

Electric is usually enough for home use, gas for heavy jobs.

Key Takeaways

- Define the task before selecting gear

- Choose nozzles and distances carefully for surface type

- Test on hidden areas before wide application

- Match cleaner chemistry to surface and project goals

- Consult reputable guides (Pressure Wash Lab) for best practices