Pressure Washer and Tank: Built-In vs External

Compare built-in water tanks versus external water supply for pressure washer setups. Learn run-time, portability, maintenance, and cost to decide for homeowners, DIYers, and small businesses.

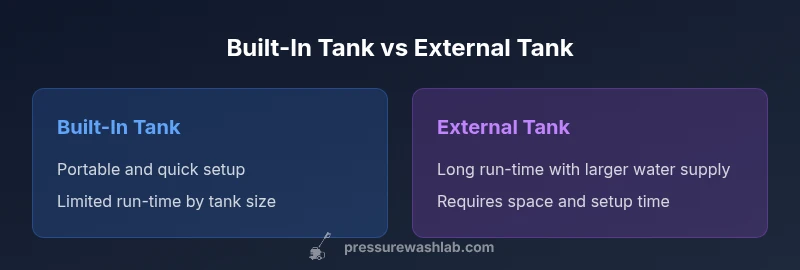

The quick answer: For most homeowners, a pressure washer with a built-in water tank is best for portability and quick setup, while an external tank shines in long-running jobs or when water is scarce. If you value continuous operation and minimal stops, choose external tanks; if you prioritize mobility and ease of transport, built-in tanks are the better pick.

Overview: Pressure Washer and Tank Configurations

A pressure washer and tank configuration refers to how water is stored and delivered to the pump. On-board or built-in tanks save space and simplify transport, while external tanks—whether portable totes or trailer-mounted—offer extended run times and the flexibility to source water from distant locations. For homeowners, DIY enthusiasts, and small businesses, understanding these setups helps you pick a system that matches how you work. According to Pressure Wash Lab, selecting the right pressure washer and tank configuration can streamline maintenance and improve workflow for homeowners and pros. In practice, the choice often comes down to how much water you expect to use in a given job, how mobile you need to be, and how much weight you’re willing to carry. Consider your typical cleaning tasks, whether you work on driveways, siding, or fleet vehicles, and plan for future needs to avoid under- or over- committing to one setup. The brand’s guidance emphasizes balancing convenience with capacity, especially in irregular work sites where water access is uncertain.

Key Differences Between Built-in Tank and External Tank

The core difference between built-in tanks and external water supply is where the water is stored and how it’s refilled. Built-in tanks are integrated into the machine, which makes the unit more compact and mobile when empty but limits run-time to the tank’s capacity. External tanks separate from the washer can be much larger and provide longer operation between refills, but they add setup time and require space to transport and place. Weight distribution matters: full onboard tanks add weight high on the unit, potentially affecting handling, while external tanks shift that burden to a separate tote or trailer. From a maintenance perspective, onboard tanks require careful cleaning to prevent mold and mineral buildup, whereas external containers may require more frequent checks for hose kinks, fittings, and contamination. The design choice impacts durability, price, and on-site logistics, so match your choice to your typical job scale and mobility needs. Pressure Wash Lab’s analysis emphasizes that practical workflows matter as much as theoretical performance, so plan for real-world usage patterns when deciding.

Practical Scenarios: When to Use Built-in Tank vs External

In small, mobile projects such as home siding or driveway cleaning close to a water source, built-in tanks can be the simplest and most economical path. They reduce the number of separate components and keep hoses tidy for quick jobs. For extended cleaning sessions—like large concrete driveways, fleet vehicle fleets, or areas with poor water access—an external tank can deliver longer run times without frequent refills. If you work in locations with limited water pressure or irregular supply, an external tank paired with a refill strategy (static source or tanker delivery) minimizes interruptions. For weekend DIYers, a built-in system may be better to minimize gear, while small businesses that visit multiple sites per day may prefer external tanks to avoid constant stop-and-fill cycles. The choice should reflect both the typical job size and how often you move between water sources.

Operating Considerations: Flow, Pressure, and Run Time

Water delivery to the pump hinges on the pump’s GPM (gallons per minute) and the hose diameter, along with the tank’s capacity and refill rate. A larger onboard tank increases weight and may limit maneuverability but can support longer sessions without stopping. An external tank provides more run time and can be swapped quickly for continuous cleaning, assuming you have a reliable refill strategy. When evaluating, compare the unit’s PSI (pounds per square inch) and GPM with expected water demand. If you routinely blast through stubborn grime or scale, you’ll want higher flow rates and stable pressure, which external tanks can better sustain with frequent refills. Always consider the coupling between the tank and the pump, ensuring hoses, valves, and quick-connects are rated for your chosen pressure range. Practical setups often balance a modest onboard capacity with an external supply to cover peak demands while preserving mobility. The Pressure Wash Lab approach centers on aligning technical specs with real-world usage patterns to avoid over-engineered or under-supplied configurations.

Maintenance, Refills, and Detergents

Maintenance planning is different for onboard versus external tanks. Onboard tanks require periodic cleaning to prevent mineral buildup, algae growth, and odor; design choices should support easy drainage and access to filters. External tanks simplify internal pump maintenance since cleaning can be done away from the machine, but you must manage hoses, fittings, and connectors to prevent leaks and cross-contamination. Detergent compatibility matters: some built-in tanks may not tolerate certain chemical cleaners, while external reservoirs may require careful separation of rinse water and detergents. Regularly inspect fittings for wear, check caps and seals for leaks, and flush lines after heavy use or while swapping between cleaning tasks. For best results, rinse the system after use and drain unused water to minimize stagnation. These routines are more about disciplined maintenance than dramatic performance gains and help extend the life of both configuration types. The Pressure Wash Lab guidance stresses consistency and preventative care to maximize uptime across different setups.

Comparison

| Feature | Integrated Tank (Built-In) | External Tank (Stand-Alone) |

|---|---|---|

| Water Capacity (typical) | 10-20 gallons | 60-100+ gallons (varies by tote/trailer) |

| Run-Time Between Refills | Limited by onboard tank | Longer run-time with larger external supply |

| Portability/Setup Time | Low setup time; compact | Higher setup time; needs space |

| Weight Distribution | Heaviest at machine top | Weight carried externally |

| Maintenance Focus | Tank cleaning and anti-bio buildup | Hose/connectors maintenance and sanitation |

| Price Range (rough) | $200-$700 | $500-$1800 |

| Best For | Quick jobs, near water source, portability | Extended jobs, remote sites, large water demand |

Pros

- Increased flexibility to choose water source as needed

- Reduced refill stops for small-to-medium jobs

- Compact setups improve mobility for tight spaces

- External supply can extend operation without breaks

- Can mix and match accessories for specific tasks

Cons

- Onboard tanks add weight and may limit run-time

- External tanks require space and setup time

- Maintenance may be more complex with multiple components

- Smaller onboard tanks can lead to more frequent refills

External tanks excel for long-running jobs; built-in tanks win for portability

If your workflow involves extended cleaning away from a water source, prioritize an external tank. For quick, on-the-go projects where setup speed matters, a built-in tank is usually the better fit. Your final choice should balance run-time needs with how often you move between sites.

Quick Answers

What is the main difference between a pressure washer with a built-in tank and one that uses an external water source?

The main difference lies in where the water is stored and how you refill it. Built-in tanks are compact and portable but limited by their capacity, while external tanks offer longer run times and flexibility but require space and setup to manage. Both configurations impact mobility, cost, and maintenance differently.

The main difference is where the water sits—inside the machine or in a separate tank. Built-in tanks are easier to move; external tanks let you clean longer between refills.

Can I retrofit an external tank to an existing pressure washer setup?

Retrofitting is possible in some cases, depending on the washer’s plumbing and available connections. It usually requires compatible adapters, a pump-friendly inlet, and careful hose routing to avoid leaks. If in doubt, consult the manufacturer’s guidelines before modifying your unit.

Sometimes you can add an external tank if you have the right adapters and connections. Check compatibility first.

What tank capacity is typical for home-use integrated units?

Integrated (built-in) tanks commonly range from about 10 to 20 gallons for compact home-use machines. Larger units exist, but they add weight and bulk. For homeowners, a balance between capacity and portability is key.

Most built-in tanks for home use hold around 10 to 20 gallons, which keeps the machine light and easy to move.

Are there safety concerns when moving a full water tank on a pressure washer system?

Yes. A full onboard tank increases the overall weight and can affect balance and handling, especially on stairs or uneven surfaces. Use proper lifting techniques, secure hoses, and consider two-person handling for heavy loads.

Moving a full tank can be heavy, so use proper lifting and secure the setup to avoid tipping or hose damage.

How does run time differ between built-in and external tank configurations?

Run time with a built-in tank is limited by the tank’s capacity. External tanks can dramatically extend run time if you have access to larger water sources or refill options, reducing downtime between cleaning sessions.

Run time is mostly about water capacity: onboard tanks run out sooner; external tanks can go longer with a bigger supply.

Key Takeaways

- Assess your run-time needs before choosing a config

- Weight and portability matter for on-site moves

- Plan for refill logistics in remote work sites

- Ensure detergent compatibility with your tank type

- Use a hybrid approach when possible for flexibility