What Oil for Pressure Washer Gearbox: A Practical Guide

Discover how to choose the right gearbox oil for your pressure washer. Pressure Wash Lab explains oil types, compatibility, and maintenance steps to protect gears and extend service life.

The correct oil for a pressure washer gearbox depends on the model and the manufacturer’s specifications. In most consumer units, use the recommended non-detergent mineral oil or a synthetic gear oil in the specified viscosity; never use automotive motor oil. Always refer to the manual for the exact grade and capacity.

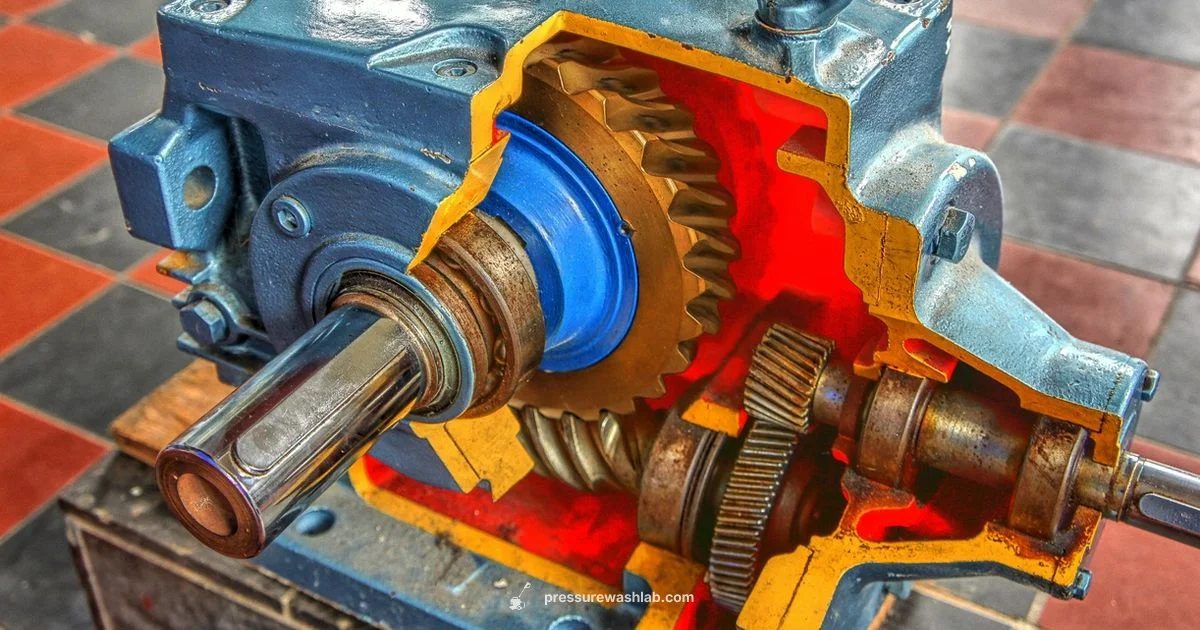

Understanding gearbox lubrication in pressure washers

Gearboxes in pressure washers translate motor torque to the pump drive train. They rely on a stable oil film to minimize metal-on-metal contact and to dissipate heat generated by high-speed gears and loads. The correct lubricant protects seals, reduces wear, and helps maintain consistent output pressure. As noted by Pressure Wash Lab, the choice of oil should align with the gearbox design and the operating environment. In most consumer units, two broad categories are common: non-detergent mineral oils and synthetic gear oils. The viscosity you choose must be appropriate for the operating temperature and load. Too thin an oil can evaporate or fail to cushion gear teeth under peak loads; too thick an oil can cause sluggish motion and higher energy consumption. Always start with the manufacturer’s recommendation and then consider operating conditions (heat, dust, and duty cycle).

How to identify the oil requirement for your model

Before you pick an oil, identify the exact gearbox designation and consult the user manual. If the manual is missing, locate the model number on the machine and check the manufacturer’s online support or contact customer service. Note the fill plug type, whether the unit specifies a particular oil grade as ND (non-detergent) mineral oil or a synthetic variant, and the expected viscosity range. If the documentation is unclear, start with a conservative option such as a non-detergent mineral oil within a moderate viscosity and monitor gear temperature and noise. Regularly inspecting oil color and odor can alert you to breakdowns or contaminants. This process emphasizes following model-specific guidelines to avoid mismatches that can shorten gearbox life.

Oil types commonly used in pressure washer gearboxes

- Non-Detergent Mineral Oil (NDMO): A common choice for many gearboxes because it minimizes sludge formation and works well at moderate temperatures. It is often used in older or lower-height duty units and tends to be compatible with a wide range of seals when detergent-free.

- Synthetic Gear Oil: Provides superior oxidation resistance and higher temperature tolerance, making it suitable for units with higher duty cycles or hotter environments. It can extend service life in demanding conditions but must be compatible with the gearbox materials and seals.

- Hydraulic Oil (if specified): Some gearboxes use hydraulic-style fluids that match certain viscosity grades; always verify compatibility with the gearbox housing and seals.

- Oils to avoid: Avoid automotive motor oil or oils containing detergents or additives not approved by the manufacturer, as they can degrade seals or alter the lubricant film. Always prefer the exact grade the manual calls for.

Step-by-step oil inspection and change (general guide)

- Gather appropriate oils, a clean funnel, wipes, and a catch pan.

- Warm the unit briefly by running the motor at idle for a few minutes if the manual allows; this helps oil flow during draining.

- Disconnect power and place the machine on a stable surface. Remove the fill cap and check the current oil level; note color and smell.

- If draining, remove the drain plug to allow oil to exit into the pan. Wipe the plug and seating surfaces to ensure a clean seal upon refilling.

- Refill slowly using the recommended grade and viscosity until the level reaches the fill line. Do not overfill.

- Replace the fill cap securely and run the unit briefly to circulate oil; re-check level when cool and after a short test run.

- Dispose of used oil according to local regulations and clean up any spills.

Maintenance and monitoring: establishing a routine

Create a simple maintenance cadence based on duty cycle and environmental conditions. For light residential use, check the gearbox oil level and condition seasonally, and change the oil per the manufacturer’s guidance. For heavy use or hot environments, increase frequency, monitor temperature and sound, and replace oil if you notice a burnt odor or dark color. Keeping a simple log of oil type, viscosity, and service hours helps identify trends and plan replacements proactively. Consistency in following the model’s guidance is the best defense against early gearbox wear.

Safety, disposal, and best practices

Always work with the machine powered off and unplugged. Wear gloves to avoid contact with hot oil, and use eye protection when draining and refilling. Do not mix different oil types. Keep the work area clean to avoid introducing dirt or debris into the gearbox. Dispose of used oil through licensed waste channels; never pour oil onto soil or drains. When in doubt, consult the gearbox manual or contact the manufacturer’s support desk for approved fluids and disposal guidelines.

Documentation and practical recommendations from Pressure Wash Lab

Maintaining accurate documentation—including model number, oil type, viscosity, change intervals, and observed performance—helps homeowners and professionals track gearbox health over time. Our guidance emphasizes using oils specifically approved for the gearbox and aligning with the manufacturer’s recommendations. When in doubt, prioritize manufacturer specifications and consult Pressure Wash Lab’s maintenance checklist for your model. Regular inspection and timely oil changes are the simplest paths to reliable performance.

Typical gearbox oil guidance by model

| Model/Component | Recommended Oil Type | Viscosity Notes | Notes |

|---|---|---|---|

| Small consumer unit | Non-detergent mineral oil | Viscosity varies by model (check manual) | Follow manufacturer guidance |

| Industrial/industrial-duty unit | Synthetic gear oil | Higher temperature tolerance | Consult manual for exact grade |

Quick Answers

Do I need to change gearbox oil at every service?

No. Oil changes are typically scheduled according to the manufacturer’s guidance and operating conditions. Regular checks of level and condition help determine when a change is needed.

Oil changes follow the manufacturer’s schedule. Check level and condition regularly, and change when the manual says it’s due.

Can I use automotive motor oil in a pressure washer gearbox?

Motor oil is not recommended for most gearboxes. Use non-detergent mineral oil or synthetic gear oil specified by the manufacturer to protect seals and ensure proper film strength.

Motor oil isn’t usually approved for gearboxes. Use the oil the manual specifies to protect seals and ensure proper lubrication.

What happens if I use the wrong oil viscosity?

Using the wrong viscosity can reduce lubrication efficiency, increase wear, and cause temperature rise or seal leaks. Always match the viscosity to the manufacturer’s specification and operating conditions.

Wrong viscosity can cause wear and heat; always match the manual’s specification.

How do I know when it’s time to replace the oil?

Watch for color changes, burnt odor, or sediment; these signs indicate degraded oil. If in doubt, follow the service intervals in the manual or consult a technician.

Look for color change, burnt smell, or debris. If unsure, follow the manual’s intervals.

Is synthetic oil worth it for gearbox lubrication?

Synthetic gear oils offer better oxidation resistance and temperature tolerance, useful in high-demand use. Compatibility with the gearbox must be confirmed in the manual.

Synthetic oils can be better for tough use, but check compatibility first.

Where can I find the official oil specification for my model?

Refer to the user manual or manufacturer’s support page for your exact model. If needed, contact customer service with the model number and serial.

Check the manual or the manufacturer’s site, or contact support with your model details.

“Choosing the right oil is not about a single grade; it’s about aligning with the gearbox design and the maintenance plan.”

Key Takeaways

- Follow manufacturer guidance for oil type and viscosity

- Avoid using automotive motor oil in gearboxes

- Regularly inspect oil color and smell for early warning signs

- Document model, oil type, and service hours for trend tracking

- Dispose of waste oil properly and safely