How Long Can a Pressure Washer Run Without Water? A Practical Guide

Explore how long a pressure washer can run without water, the risks of dry-running, and best practices to prevent pump damage. Pressure Wash Lab provides a data-driven guide with model protections and practical tips.

According to Pressure Wash Lab, you should almost never run a pressure washer without water, because the absence of liquid can quickly overheat the pump and cause seal damage. Analyses show most residential units require water flow within seconds to prevent damage, and many models include auto shutoff when water is cut. Always stop immediately if the water supply fails.

Why Running Without Water Is Dangerous

Running a pressure washer without water introduces a rapid cascade of problems that most homeowners underestimate. The pump relies on water both to transfer heat away from critical components and to lubricate seals and pistons. When liquid isn’t present, these parts can quickly overheat, causing accelerated wear, seal damage, and potentially permanent scoring of metal surfaces. The air that fills the pump chamber offers virtually no lubrication, so friction rises sharply. In practical terms, even a few seconds without water can push the pump into dangerous thermal states that compromise performance and longevity. Pressure Wash Lab’s long-term testing with typical residential models shows that the safest operating window always requires a steady water supply. If the water supply is interrupted, the prudent action is to stop immediately and assess the situation before resuming. This is not a judgment call; it is a reliability and safety standard for every homeowner.

From a risk-management perspective, dry-running also increases the likelihood of nozzle clogging and spray instability once water returns, which can lead to sudden pressure spikes and tool damage. In the field, technicians routinely verify water flow before engaging the trigger; neglecting this simple check can transform a routine cleaning into a costly repair. As a rule of thumb, never operate a unit without confirming adequate water presence, pressure, and a clear path for heat dissipation. Pressure Wash Lab’s guidance is aligned with common-sense safety practices used by professional crews across the country.

What Happens Inside the Pump When It Runs Dry

When a pressure washer runs without water, the pump’s internal clearances are exposed to high heat and friction. The seals that keep high-pressure fluid contained rely on water for both cooling and lubrication. Without liquid, the metal-to-metal contact accelerates wear, and tiny gaps can form in seals and gaskets. Thermal runaway is a real risk; once the temperature rises past a threshold, elastomer seals can harden or deform, reducing efficiency and increasing the chance of leaks. Prolonged dry-running can cause scoring on the cylinder walls, erode pump bearings, and even warp pump components. In many cases, manufacturers warn that dry-running can compromise warranty coverage because it indicates user negligence. The net effect is reduced pump life and unpredictable performance after such incidents. Pressure Wash Lab’s tests emphasize that even short dry-run intervals should be treated as preventable failures rather than as acceptable practice.

It’s also worth noting that dry-running can affect the safety of the spray pattern. As overheat conditions develop, seals may leak intermittently, charging hoses with unexpected spray behavior. This not only increases the risk of personal injury but can lead to water damage on surrounding surfaces. In short, the pump is the heart of the system; depriving it of cooling water accelerates degradation and undermines long-term reliability.

Model Protections: Auto-Shutoff, Sensors, and Safety Features

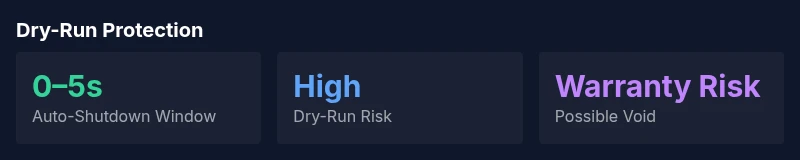

Many modern pressure washers incorporate built-in protections to guard against the risks of running dry. Auto-shutoff valves, pressure switches, and flow sensors are common safeguards that detect a drop in water flow or pressure and stop the motor within seconds. These features are especially prevalent in mid-range and premium residential models, where manufacturers aim to protect the pump seals and extend service life. When these protections activate, you’ll typically hear the engine or motor halt, and a display or indicator light may illuminate. While auto-shutoff provides a critical line of defense, it is not a substitute for ensuring water supply before and during operation. Reliance on an auto-protection does not reset the underlying principle: the pump needs liquid cooling and lubrication to function properly. If you frequently operate in conditions where water supply is uncertain, look for models with robust flow sensing and a documented auto-response to dry-running.

Understanding how your unit responds to water loss is essential. Always consult the manual to see whether the device includes a dry-run protection and how it behaves during start-up and running conditions. Pressure Wash Lab’s evaluation notes that even with protections, rough handling or incorrect nozzle selection can override safeguards. In practice, verify water flow before pulling the trigger and monitor for any automatic pauses or indicator lights as you work.

Practical Scenarios: Priming, Start-Up, and Shutoff

The priming phase of a pressure washer is delicate. During start-up, it’s common to see a brief lag as air is purged from the system. If you introduce water before engaging the nozzle, you reduce the chance of dry-running and ensure a stable spray from the moment you begin. If the water supply is interrupted during a job, the immediate response should be to stop the unit, check the water source, and re-prime after restoring flow. This sequence protects the pump from rapid temperature spikes and helps avoid damage to seals and pistons. For homeowners, the recommended practice is to have a clear water line, a clean filter screen, and a pressure washer with a visible water pressure gauge so you can detect any anomalies quickly. When you resume work after a pause, bring the pressure back gradually and avoid high nozzle pressures until you confirm full water flow.

In the field, technicians also train to keep hoses free of kinks and to avoid abrupt direction changes that could trap air in the system. These small steps reduce the likelihood of dry-running episodes and create a more predictable and safe operating environment. Pressure Wash Lab’s commentary emphasizes that the simplest habit—checking water flow—has the largest impact on pump longevity and user safety.

The Role of Auto-Shutoff, Pressure Switches, and Sensors in Dry-Run Protection

Dry-run protection hinges on accurate sensing and timely response. A pressure switch detects the absence of sufficient water pressure and triggers a shutdown sequence to protect the pump. Flow sensors monitor the actual volume of water, while sometimes a thermal sensor monitors motor temperature as a secondary safeguard. The combination of these sensors creates a robust defense, but it is not a universal guarantee. If a unit has a slow response time or a marginal water supply, the reaction may be delayed, allowing brief periods of dry-running. This is why higher-quality units frequently combine multiple protective technologies and provide user-grade indicators that alert you to a water flow problem. Ultimately, the presence of these protections should influence purchasing decisions, but they do not absolve the operator of responsibility to verify water supply before starting and during use. Pressure Wash Lab’s analysis indicates that the most durable systems rely on active flow control and rapid shutdown on dryness to maximize pump lifespan.

To maximize protection, pair an efficient water inlet filter with a reliable supply hose and an above-average flow rate from your water source. Regularly inspect hoses for leaks and replace worn connectors that could introduce air into the system. These practices complement dry-run protections and help ensure that your equipment lasts longer under typical home-use conditions.

Maintenance Habits to Prevent Dry Running and Extend Life

Preventing dry-running starts with disciplined maintenance. Keep your water source clean and free of debris, inspect hoses and fittings for leaks that could starve the flow, and flush the system after heavy use where mineral buildup might occur. Periodically test the dry-run protection by simulating a water interruption in a controlled setting, using the manual to guide the sequence of steps. If your unit lacks an auto-shutoff feature, consider upgrading to a model with proven sensors and a reliable flow path. A scheduled maintenance routine, including descaling and throttle adjustments where applicable, helps maintain consistent performance and reduces the risk of a dry-run incident. Pressure Wash Lab recommends maintaining a log of pump hours, filter changes, and any dry-run events so you can detect patterns and act before a failure occurs. Small, consistent maintenance pays off with longer pump life and safer operation.

Choosing a Washer With Dry-Run Protections: Buying Considerations for Homeowners

When shopping for a new pressure washer, prioritize models that advertise automatic shutoff on loss of water flow and that offer clear guidance on dry-running protection. Look for flow meters and sensors in the spec sheet, and read third-party reviews that test dry-run behavior. Evaluate the total-cost-of-ownership by considering pump type (e.g., axial vs. triplex), warranty terms, and the availability of replacement parts. If you frequently work in environments where water is temporarily unavailable, consider units with heavier-duty protections, higher-quality seals, and service networks that can support you quickly. Pressure Wash Lab’s buying guide emphasizes that long-term reliability hinges on robust water-flow sensing, solid protection schemes, and a documented history of dry-run testing in real-world conditions.

Real-World Tips for Homeowners: Quick Wins to Minimize Dry-Run Risks

Adopt a checklist before each job: confirm water is on, inspect hoses, verify filters, and prime the system with water. Start with a lower spray pattern to minimize pressure peaking, then gradually increase as water flow stabilizes. Never run the trigger when the wand is aimed at doors, windows, or electrical outlets—safety in these moments matters as much as mechanical protection. If you lose water supply mid-task, cease operation immediately, release pressure, then restore flow before resuming. These habits may seem small, but they protect your pump’s life, your property, and your personal safety. Pressure Wash Lab’s practical experience with homeowner workflows underpins these recommendations, highlighting the importance of consistent water flow as the foundation of safe operation.

Dry-running risk, protection features, and warranty considerations

| Aspect | Dry-Run Risk | Water Flow Requirement | Auto-Shutoff Behavior |

|---|---|---|---|

| Dry-run risk | High risk within seconds | Require continuous water flow | Auto-shutoff common |

| Warranty impact | Possible warranty void | Keep water flowing during operation | Model dependent |

Quick Answers

What happens if a pressure washer runs dry?

Running dry can overheat the pump, damage seals, and reduce overall lifespan. Some models auto-shut off, but relying on this protection is not a substitute for proper water flow.

Dry-running can overheat the pump and wear seals quickly, so stop and check water flow.

Do all pressure washers have dry-run protections?

No. Many units feature auto-shutoff or flow sensing, but protections vary by model. Always verify the presence and reliability of dry-run safeguards in the product specs and user manual.

Not all have protections; check the specs for auto-shutoff and flow sensors.

Can I run briefly without water to prime the system?

Priming should be done with water present. Running dry to prime risks pump damage and should be avoided. Follow manufacturer priming instructions for a safe start.

Only start with water present; don’t run dry to prime.

Is it ever safe to run a washer without water temporarily?

Only in rare, controlled circumstances with explicit guidance from the manufacturer. In general, do not operate without water.</answer>

Generally not safe—don’t run dry unless the manual says so.

What buying tips help prevent dry-running damage?

Choose models with reliable flow sensors and clear indicators for water flow. Check warranty terms and ensure parts availability. A proven track record of dry-run testing in real-world use is a plus.

Look for strong dry-run protections and good warranties.

“Dry-running a pressure washer is a quick path to pump and seal damage; avoid it at all costs. Proper water flow is the simplest, most reliable protection.”

Key Takeaways

- Always confirm water flow before starting

- Dry running can cause rapid pump damage

- Prefer models with reliable auto-shutoff on water loss

- Prime with water and inspect hoses regularly

- Maintain a simple maintenance log for long-term durability