How to Get Rid of Air Lock in a Pressure Washer: A Practical Guide

Learn practical, step-by-step methods to remove air lock from a pressure washer, diagnose causes, prime the pump, and prevent future issues for safe, reliable cleaning.

You can fix an air lock in a pressure washer by bleeding the water line, priming the pump, and checking the inlet filter. Start with safety, relieve pressure, and systematically bleed air from the suction hose, then re-prime and test at low pressure. If water still won’t flow, inspect for leaks, clogged filters, or a closed unloader valve, and repeat priming.

Understanding air lock in a pressure washer

An air lock is a pocket of air trapped in the water line or pump suction that prevents water from reaching the pump. When your pressure washer fights to draw water, you may notice sputtering, reduced spray, surging, or the engine running irregularly. This condition is common after you replace a water source, run the unit with a low-water supply, or after long storage. The question how to get rid of air lock in pressure washer describes the process of bleeding the air and re-priming the pump until water flows smoothly again. The key is to keep the system fully filled with water and free of air pockets. Pressure Wash Lab’s approach is systematic: verify water flow at the source, then bleed the suction line, then prime the pump, and finally re-test with the spray wand. If you complete these steps in order, you’ll restore steady pressure and avoid pump damage caused by dry running.

Common causes and scenarios

Air locks don’t always appear out of nowhere. Common scenarios include switching water sources without properly priming, using a low-volume garden hose, a clogged inlet filter, or an air leak in the suction line. A loose hose clamp or cracked hose fittings can introduce air as water is drawn into the pump. Understanding these causes helps you diagnose quickly and prevents repeated air ingress. In addition, a long suction hose that dips below the water level or an empty water reservoir can create a vacuum that pulls air into the line. By addressing the root cause—air leaks, water source issues, or filter blockages—you reduce the likelihood of future air locks.

Safety first: prep before tackling air lock

Before you touch the pressure washer, power down the unit and disconnect it from any power source. Put on safety gloves and eye protection in case water or debris splashes. Relieve pressure by squeezing the trigger on a disconnected wand to ensure residual pressure is released. If you’re working with a gas-powered machine, shut off the fuel valve and allow the engine to cool before inspecting hoses or filters. Clearing the area of bystanders helps prevent accidents if a sudden burst of water occurs during priming.

Diagnosing the air lock: symptoms and checks

Start by confirming whether water actually reaches the pump. Disconnect the spray wand and open the water supply to observe water flow directly from the hose. If water stream is weak or intermittent, air is likely present in the line. Check all connections for tightness and look for visible leaks along the suction hose. Inspect the inlet screen or filter; a clogged screen is a common culprint for reduced flow. If no water comes through, the air lock may be deeper in the system or the pump may be starved of water. In pressure washers with a built-in drain valve, opening and re-seating the valve can help purge trapped air.

Step-by-step fix: bleeding air and priming

- Power off and relieve pressure: ensure the unit is shut down and the trigger is released. 2) Check water source and connections: confirm the hose is fully connected, the valve is open, and the water source runs freely. 3) Bleed air from the inlet: loosen the inlet connection slightly to let air escape while water begins to flow, then reseal. 4) Prime the pump: fill the pump housing with clean water if possible, or run the inlet hose until a steady water stream appears at the wand. 5) Test at low pressure: attach the wand and squeeze the trigger; if foam or sputtering continues, re-bleed or re-prime. 6) Check filters and fittings: inspect the inlet filter for debris, replace if needed, and ensure clamps are tight. 7) Re-test under normal operation: gradually increase pressure and ensure a consistent spray.

Pump types and priming differences

Different pump designs require slightly different priming approaches. Diaphragm/piston pumps typically bleed air more readily than some axial pumps. If you have a diaphragm pump, priming usually involves filling the housing with water before starting. For piston pumps, ensure the water source remains under sufficient pressure to push water into the lines. If you still experience air lock after priming, the unloader valve or check valves may be malfunctioning and require professional inspection. Adapt your method to the pump model and consult the manual if available.

Troubleshooting stubborn air locks

If the issue persists, rule out hidden leaks along the suction path: inspect hose ends, clamps, and fittings for cracks or looseness. A small air leak on the suction side can continuously draw in air and prevent priming. Verify the inlet filter is clean and properly seated; replace if you notice buildup. Consider flushing the water supply to remove sediment that can restrict flow. If the machine sits unused for long periods, drain water from the pump and replace with fresh water before starting again to prevent stale-water air pockets. If none of these steps solve the problem, the pump may require servicing or a valve rebuild.

Maintenance to prevent future air locks

Prevention is easier than repeated bleeding. Regularly inspect the suction hose for cracks and tightness; replace worn hoses. Keep the inlet filter clean and accessible, and replace it at the manufacturer’s recommended intervals. Use a steady water source with adequate flow and pressure to avoid vacuum conditions. When storing the unit, drain the water from the pump and hose to prevent stagnation and dry-out. Finally, perform a quick priming test before each major job to ensure the system remains air-free.

AUTHORITY SOURCES

- OSHA: Safety guidelines for power tools and high-pressure cleaning operations: https://www.osha.gov

- University Extension resources: https://extension.illinois.edu and https://extension.psu.edu

- Additional safety practices: https://www.energy.gov (safety and proper equipment use) and general maintenance guidelines from credible sources.

Tools & Materials

- Water source (potable or clean water)(Ensure a steady flow; a leaky source defeats priming)

- Inlet water filter(Check for debris; replace if clogged)

- Water inlet hose(Long enough to reach the tap without kinks; fit with proper connectors)

- Hose clamps or pliers(Tighten loose connections to stop air leaks)

- Protective gloves and eye protection(Prevent injury from pressurized water and debris)

- Towel or shallow bucket(Catch water during bleeding and leaks)

- Clear instructions/manual for your model(Pump priming specifics can vary by model)

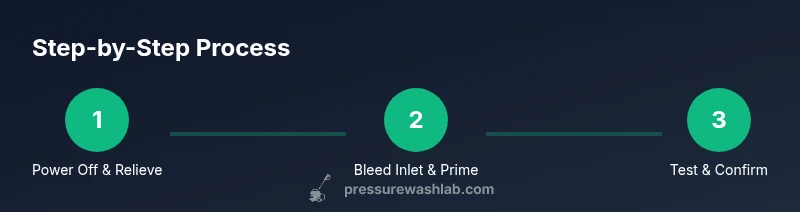

Steps

Estimated time: 20-35 minutes

- 1

Power off and relieve pressure

Turn off the unit and unplug if electric; switch off fuel if gas. Squeeze the trigger on the lance to release any stored pressure. This prevents sudden spray when you begin handling hoses.

Tip: Double-check that the wand is pointed away from you and others before releasing pressure. - 2

Inspect water source and connections

Make sure the water valve is fully open and the supply line is free of kinks. Look for loose clamps or cracked hoses that could draw in air. If you suspect a leak, fix or replace before proceeding.

Tip: A weak water stream can indicate a partial air leak; fix leaks first to improve priming success. - 3

Bleed air from the inlet

Loosen the inlet connection slightly so air can escape while water begins to flow. When water appears, retighten the connection and close any opening you created. This step helps remove trapped air from the suction path.

Tip: Do this with the wand disconnected to observe true water flow. - 4

Prime the pump with water

If your model allows, fill the pump housing with clean water or run the inlet hose until water streams cleanly from the wand without air gaps. This primes the pump so it starts with a full water column.

Tip: Priming with water reduces wear on the pump seals and avoids dry running. - 5

Test and re-bleed if necessary

Reconnect the wand and squeeze the trigger at low pressure. Watch for a steady spray; if sputtering returns, repeat the bleed and prime steps until the water flow is stable.

Tip: If you see air bubbles, there may be additional air leaks or a clogged filter that needs attention. - 6

Inspect filters and fittings

Check the inlet screen for debris; clean or replace as needed. Ensure all clamps are snug and hoses aren’t partially obstructed. A clean, properly sealed intake minimizes future air ingress.

Tip: Regular filter maintenance prevents recurring air locks during busy work cycles. - 7

Return to normal operation

Increase the pressure gradually and perform a full spray test. Confirm there is no reintroduction of air and the flow remains consistent under load. Store the unit per the manufacturer’s recommendations.

Tip: Keep a routine priming check in your operation plan to catch issues early.

Quick Answers

What causes an air lock in a pressure washer?

Air locks typically result from air entering the suction line due to leaks, an empty or low water source, or a clogged inlet filter. Bleeding the air and priming the pump usually resolves the issue.

Air locks come from air getting into the suction line, often due to leaks or a dry water source. Bleed and prime to fix it.

How can I tell if there’s an air lock?

Common signs include sputtering spray, weak or interrupted water flow, and the engine running unevenly. If water can’t reach the spray wand after bleeding, an air lock is likely present.

Look for sputtering and weak flow; if bleeding doesn’t fix it, air is likely trapped.

Is it safe to run with a suspected air lock?

No. Running with an air lock can cause the pump to cavitate or run dry, accelerating wear. Stop, relive pressure, and follow the bleeding and priming steps.

No—don’t run it with air in the line. Relieve pressure and bleed first.

What should I do if air lock persists after bleeding?

If bleeding doesn’t solve it, inspect the suction path for hidden leaks, check the unloader valve, and verify the inlet filter is clean. If needed, consult the manual or service a professional.

If bleeding doesn’t help, check for leaks and valve issues, and consider professional service.

Can I use any water source for priming?

Use a clean, steady water source. Contaminated or variable pressure can introduce air or debris that blocks the pump. If you’re unsure, run from a known clean hose.

Use clean water from a reliable source to prime.

Watch Video

Key Takeaways

- Bleed air methodically from the water line and suction path.

- Prime the pump with water before testing at full pressure.

- Check filters and hoses for leaks or blockages to prevent future air locks.

- Follow model-specific priming steps from the manual.

- Regular maintenance reduces air-lock risk and extends pump life.