How to Use a Pressure Washer in Crime Scene Cleaning

A practical, safety-focused guide for professional crime scene cleaning teams on using a pressure washer within a controlled decontamination workflow.

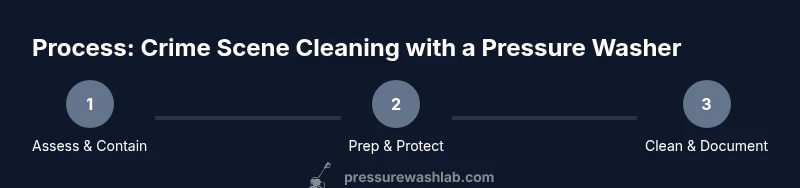

Using a pressure washer in crime scene cleaning is allowed only within a controlled decontamination workflow under professional supervision. Begin with hazard assessment, PPE, and containment; select a suitable nozzle for non-porous surfaces and apply low-to-moderate pressure. Avoid porous materials and aerosols; comply with local regulations, manufacturer guidance, and thorough documentation after the rinse.

Safety and regulatory foundations

Crime scene cleaning involves handling biological hazards and potentially contaminated environments. Before operating a pressure washer, perform a thorough hazard assessment, establish containment zones, and ensure you comply with local, state, and federal regulations. PPE is non-negotiable: use disposable gloves, splash protection, an impermeable suit, and boot covers. Training and certification requirements vary by jurisdiction, so verify local rules before work begins. Document scene boundaries, waste handling, and decontamination steps to support accountability and post-incident reporting. According to Pressure Wash Lab, adhering to a formal protocol reduces risk to workers and occupants and aligns with best practices in 2026.

Equipment selection and setup

Choose a pressure washer with reliable safety features (automatic shutoff, chemical injection compatibility, and appropriate flow control). Attach a surface cleaner or wide-throw nozzle to minimize splatter and keep the spray pattern controlled. Ensure a stable water supply with backflow protection, and use hoses rated for the environment. Do not operate the unit without proper pre-checks or without a containment plan. Always test run in a controlled area first to confirm there are no leaks or backflow issues. Maintenance and pre-cleaning checks reduce the chance of cross-contamination during the main cleaning pass.

Cleaning workflow: scene to sanitation

Adopt a stepwise workflow: stabilize the scene, remove obvious debris, apply approved cleaning solutions to target zones, and then rinse with the pressure washer. Work from the cleanest area toward the dirtiest to minimize cross-contamination. Allow surface dwell times per product labels where applicable, and avoid creating aerosols by maintaining appropriate spray angles and distances. After rinsing, inspect for residual staining or contaminants, re-treat if necessary, and move to the decontamination phase with approved disinfectants. Finally, document each step and log waste disposal to satisfy regulatory and client requirements.

Surface considerations and nozzle choices

Surface type drives nozzle selection and technique. Non-porous, sealed surfaces (like sealed concrete or metal) respond well to controlled rinses, while porous materials (such as untreated wood or certain fabrics) are more challenging and may require gentler methods or alternative cleaning approaches. Use wide dispersion or low-pressure nozzles to minimize forceful impacts on fragile materials. When in doubt, start with the gentlest setting and gradually increase only as needed, monitoring for surface damage and debris resuspension.

Containment, ventilation, and biohazard controls

Containment is essential to protect workers and bystanders. Set up barriers, keep the cleaning area ventilated, and use negative-pressure strategies if available. Do not spray into occupied spaces or areas without adequate exhaust. Ventilation helps dilute aerosols and reduces exposure risk. Establish a controlled flow path so contaminants don’t migrate to clean zones, and ensure all personnel are trained to recognize airborne hazards and follow proper decontamination procedures for footwear and gear.

Post-cleaning decontamination and waste disposal

Once cleaning is complete, perform a secondary decontamination pass on equipment, hoses, and surfaces that may have been exposed to contaminants. Rinse and wipe down all gear with approved disinfectants, then remove PPE in a controlled sequence to avoid self-contamination. Secure and label all waste bags and containers for proper disposal according to local hazardous waste guidelines. Maintain thorough records, including waste manifests, for regulatory compliance and client documentation.

Maintenance and safety for ongoing operations

Regular maintenance of the pressure washer, hoses, and attachments is critical to prevent failures that could compromise safety. Clean equipment after use, inspect hoses for wear, replace worn parts promptly, and store gear in a clean, dry area. Schedule periodic training refreshers on biohazard controls and decontamination best practices to stay compliant with evolving regulations and to keep crews confident in their safety procedures.

Common mistakes and how to avoid them

Common errors include using excessive pressure on porous materials, skipping containment, and bypassing disinfection steps. Always verify product labels for dwell times and compatibility with your surfaces, and never mix cleaners improperly. Implement a written procedure, conduct pre-job dry runs, and review lessons learned after each cleanup to improve future performance.

Tools & Materials

- PPE kit (gloves, goggles, face shield, impermeable suit, boot covers)(Ensure PPE is rated for hazard exposure and fits properly.)

- Pressure washer with adjustable nozzle and safety features(Prefer units with variable pressure and chemical compatibility.)

- Backflow preventer and certified water supply hose(Prevents contamination of the water supply.)

- Surface cleaner attachment or wide-throw nozzle(Reduces splatter and maintains uniform coverage.)

- Biohazard bags and sealed waste containers(Use red or clearly labeled bags per local guidelines.)

- EPA-registered disinfectants suitable for biohazards(Follow label instructions and dwell times precisely.)

- Absorbent materials for initial spill management(Useful for quick containment before washing.)

- Containment barriers and signage(Mark the work area and restrict access.)

- Decontamination wipes or spray for tools(Keeps equipment clean between passes.)

Steps

Estimated time: 2-3 hours

- 1

Assess hazards and plan

Walk the scene with the lead investigator to identify hazards, boundaries, and critical zones. Establish containment, ventilation, and a clear work plan before any tools are turned on.

Tip: Create a boundary map and assign roles to maintain accountability. - 2

Don PPE and set up equipment

Put on full PPE and connect the water supply with backflow protection. Perform a functional test of the washer in a controlled area.

Tip: Double-check seals and tighten connections before starting. - 3

Remove visible debris and prep

Bag and remove obvious solid waste. Pre-clean loose debris to reduce bulk before applying detergents.

Tip: Work from the cleanest zone outward to minimize tracking contaminants. - 4

Apply cleaning solution and dwell

Apply an appropriate solution to affected surfaces and allow dwell time per label. This helps break down organic material before rinsing.

Tip: Do not mix cleaners; follow label directions for compatibility. - 5

Rinse with pressure washer

Rinse surfaces using a wide spray pattern, moving steadily to avoid hot spots. Maintain a safe distance and angle to prevent splatter.

Tip: Keep the nozzle moving and avoid vertical sprays that can redirect contaminants. - 6

Decontam equipment and dispose waste

Clean hoses and attachments with disinfectant; seal and dispose of waste according to local rules. Label all containers clearly.

Tip: Rinse thoroughly to remove residues that could transfer contaminants. - 7

Document and close out

Record actions taken, waste disposal, and decontamination outcomes. Debrief with team and prepare the site for release.

Tip: Capture photos and maintain a traceable chain of custody.

Quick Answers

What surfaces are safe to treat with a pressure washer during crime scene cleaning?

Non-porous, sealed surfaces like certain metals and sealed concrete can be treated with controlled pressure. Porous materials may require gentler methods or removal from the area to prevent damage or contamination spread.

Non-porous surfaces are generally safer for pressure washing; porous materials may need gentler methods or removal from the area.

Is it necessary to use a pressure washer at all in crime scene cleaning?

A pressure washer is a tool within a broader decontamination protocol. It should only be used by trained professionals as part of a documented workflow, not as a first-line stand-alone solution.

A pressure washer is a tool within a broader, documented decontamination protocol and should be used by trained professionals.

What are the PPE requirements for this work?

PPE should include gloves, eye protection, a respirator as needed, a protective suit, and boot covers. Training on proper donning and doffing is essential to minimize exposure.

Wear full PPE and training on donning and doffing is essential.

Can household cleaners be substituted for professional products?

Household cleaners may not meet regulatory or biohazard decontamination standards. Use EPA-registered products approved for biohazard cleanup, following label directions closely.

Don’t substitute household cleaners; use approved biohazard cleaners and follow their labels.

What should I do with waste after cleaning?

Seal waste in labeled bags and containers for hazardous waste disposal. Follow local regulations for transport and disposal, and maintain documentation.

Seal waste properly and follow local disposal rules with documentation.

Should I hire professionals for crime scene cleanup?

Yes. Trained professionals understand hazards, regulations, and proper decontamination procedures to minimize risk to people and property.

Yes—professionals have the training and equipment to handle biohazards safely.

Watch Video

Key Takeaways

- Follow a formal hazard assessment before starting.

- Use PPE and containment to protect workers and bystanders.

- Choose appropriate nozzle and pressure for surface type.

- Document all steps and waste for compliance.