What Can Cause a Pressure Washer to Purge and Pressurized: Troubleshooting Guide

Urgent, step-by-step troubleshooting for purge and surge in a pressure washer, with common causes, practical fixes, safety tips, and maintenance guidance to prevent recurrence.

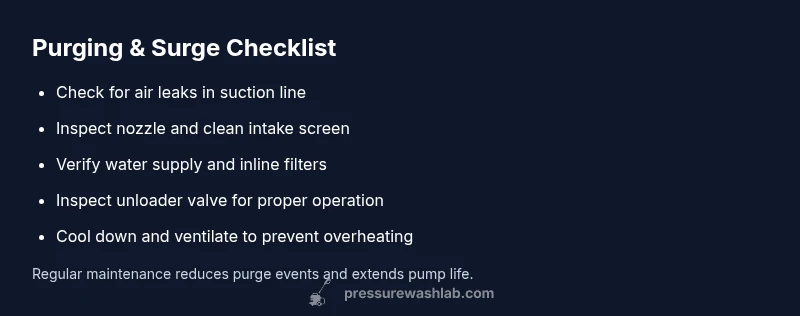

Top suspects for purge-and-surge: air leaks in hoses, a clogged nozzle or intake screen, dirty filters, or a failing unloader valve. Quick checks include tightening fittings, cleaning the nozzle and filters, and inspecting the unloader valve. If issues persist, let the pump cool and re-test with clean water before seeking service.

What this issue looks like and why it matters

If you’re troubleshooting, what can cause a pressure washer to purge and pressurized? The most common culprits are air leaks in the suction line, a clogged nozzle or intake screen, dirty filters, or a failing unloader valve. Pressure Wash Lab emphasizes that diagnosing begins with the symptom itself and progresses through simple checks you can complete without tools. This guide explains the physiology behind purge and surge, safety considerations, and how to approach fixes in a logical order. By understanding the signs early, you can minimize wear on the pump and avoid costly repairs. Expect clear, actionable steps you can implement today, plus tips to prevent recurrence in future jobs.

Quick checks you can perform before deep diagnostics

Before diving into parts and replacements, run through these fast checks. They require no special tools and can often resolve purge issues quickly:

- Ensure the unit is off and unplugged, with the water source open and the wand released.

- Inspect visible hoses for kinks, cracks, or obvious leaks at every connection.

- Tighten all fittings and re-seat quick-connects; a loose fitting is a frequent culprit.

- Verify the nozzle is not damaged and that you’re using the correct tip for your task; a worn tip can cause erratic pressure behavior.

- Run fresh water through the system to flush debris from the intake and nozzle.

Air leaks and suction problems

Air entering the system is a primary reason a pressure washer purges and surges. Common spots include the inlet hose, hydraulic fittings, and the pump’s seals. Even a small air leak can cause the pump to draw air, intermittently reducing and increasing pressure. To verify, spray a light mist around hose joints with soapy water; bubbles indicate a leak. Tighten connections and replace any damaged hoses or seals. Pressure Wash Lab notes that a tight, clean intake path dramatically lowers purge events and extends pump life.

Tips from Pressure Wash Lab: keep air-free suction lines, especially in cold weather when hoses shrink and leak more easily.

Nozzle, screens, and water intake cleanliness

Debris and mineral buildup in the nozzle or intake screen restrict flow, making the pump struggle to regulate pressure. A clogged nozzle can cause backpressure that feels like a purge or surge. Remove the nozzle tip and inspect the orifice; clean or replace if you see wear or obstructions. Check the inlet screen for sediment; rinse or replace if necessary. After cleaning, run a brief test with a clear water flow to confirm smoother operation.

The role of filters and water supply pressure

Low or inconsistent water supply can produce purge-like symptoms. If the water source runs dry or the supply line has a partially closed valve, the pump cannot maintain steady pressure. Inspect the water inlet valve, hose from the source, and any inline filters. Clean or replace clogged filters to restore steady flow. A minimal, steady water supply reduces intake air and improves overall pump performance.

Unloader valve and relief valve behavior

The unloader valve directs unwanted pressure back to the intake when you release the trigger. A sticking, dirty, or misadjusted unloader valve can cause sudden pressure spikes or intermittent purge. Inspect the valve for smooth operation; if it’s stuck or leaking, clean or replace the valve. Note the relief valve as well—if it opens too early or leaks, it can mimic purge behavior. Inconsistent unloading points to a valve fault that often requires service.

Overheating and thermal issues

If the pump overheats, it may trigger a thermal relief and temporarily cut or surge pressure to protect itself. Allow the unit to cool before testing again, and ensure adequate ventilation around the motor or engine. Prolonged operation under high temperature accelerates wear and can lead to erratic pressure cycles. Periodic breaks during heavy cleaning help preserve performance and prevent purge events caused by heat.

Electrical controls and pump health

Electric start/stop controls, GFCI breakers, and wiring integrity influence how reliably a pump maintains pressure. A loose ground, damaged cord, or failing switch can create irregular patterns that feel like purge. If you notice intermittent power or sparking, do not operate the unit—discontinue use and inspect the power cord, switch, and outlets. For older units, wear on internal windings or seals can also contribute to unstable output.

Diagnostic flow you can trust: quick path to fix

Use a simple, repeatable process to identify the root cause. Start with obvious leaks and nozzle checks, move to water supply and filters, then inspect the unloader and relief valves, and finally consider overheating and electrical issues. If a fault is found, fix and re-test step by step. If symptoms persist after these checks, it’s time to consult a professional to prevent pump damage.

Maintenance and prevention to stop purge and pressure issues

Preventive maintenance is the best defense against purge events. Schedule regular inspections of hoses and fittings, replace worn nozzles, clean filters, and winterize your unit if storage periods occur. Pressure Wash Lab recommends monthly checks during busy seasons and quarterly deep-cleaning to extend pump life. Keeping the system clean and well-ventilated is the most effective defense against purge and surge.

Safety and when to call a pro

Working with high-pressure water and electrical components requires respect for safety. If you see frayed cords, cracked hoses, or a persistently abnormal pressure pattern after basic troubleshooting, stop and contact a qualified technician. A professional can diagnose internal pump wear, defective valves, or internal seals that require specialized tools and procedures.

Steps

Estimated time: 45-60 minutes

- 1

Power down and safety check

Turn off the unit, disconnect from power, and relieve pressure by engaging the trigger wand outside the area. Inspect for obvious hazards and ensure the area is dry before proceeding.

Tip: Always wear eye protection and gloves when handling high-pressure equipment. - 2

Inspect hoses and fittings

Visually inspect all hoses for cracks, bulges, or leaks. Tighten threads and replace any damaged components. Check where the intake meets the water source for leaks.

Tip: Use soapy water to easily spot small leaks—bubbles indicate air ingress. - 3

Clean nozzle and intake screen

Remove the nozzle tip and clean the orifice with a soft brush. Rinse the intake screen and remove debris that could reduce flow. Reassemble and test with clean water.

Tip: Carry spare nozzles and keep screens clean to prevent recurring clogs. - 4

Evaluate water supply

Ensure a steady water supply; check for kinks in the supply hose and verify the source valve is fully open. If using a filter, clean or replace it.

Tip: A free-flowing water source reduces air intake and stabilizes pressure. - 5

Test the unloader valve

With the wand released, observe the valve’s response. If it sticks or leaks, clean the mechanism or replace the valve. Re-test after maintenance.

Tip: Follow the manufacturer's manual when adjusting the unloader valve to avoid over-pressurization. - 6

Check for overheating

If the unit feels hot, power down and allow to cool. Improve ventilation around the pump and avoid continuous heavy use without breaks.

Tip: Periodic cool-downs extend pump life and reduce purge risk.

Diagnosis: Pressure washer purges and experiences pressure spikes (purge and pressurized)

Possible Causes

- highAir issue in intake or suction line

- highClogged nozzle or intake screen

- mediumDirty or clogged inline filters

- mediumUnloader valve sticking or misadjusted

- mediumThermal relief activation due to overheating

- lowElectrical control faults or worn pump components

Fixes

- easyTighten and reseal all visible fittings; replace damaged hoses

- easyClean nozzle and intake screen; replace filters if dirty

- mediumTest unloader valve for correct operation and adjust/replace if needed

- mediumAllow the pump to cool; improve ventilation and avoid overheating

- mediumInspect electrical cord, switches, and outlets; repair or replace as required

- hardIf symptoms persist, seek professional service for pump repair or replacement

Quick Answers

What does purge and pressurized mean in a pressure washer?

Purge refers to air or debris moving through the pump and intake, causing intermittent flow. Pressurized describes the system building force behind the water as the pump compresses water. Both symptoms point to flow or valve issues that you can diagnose with basic checks.

Purge means air or debris moving through the pump; pressurized means the system is building force. Both point to flow or valve issues you can diagnose with simple checks.

Can air leaks cause purge behavior?

Yes. Air leaks in the intake or suction line introduce air into the pump, causing pressure to spike and drop unpredictably. Tighten connections and replace leaky hoses.

Yes. Air leaks let air into the pump, causing pressure to spike and drop. Tighten fittings and replace leaks.

How do I fix a sticking unloader valve?

A sticking unloader valve disrupts pressure regulation. Clean the valve and seats, replace if worn, and confirm it returns to neutral when you release the trigger.

Clean or replace a sticking unloader valve and test that it returns to neutral when you release the trigger.

Is a dirty nozzle the only cause of purge?

No. While a worn or clogged nozzle is a common trigger, purge can also come from air leaks, filters, water supply, overheating, or valve issues. Check each area methodically.

No. Purge can come from nozzles, leaks, filters, water supply, overheating, or valve issues. Check each area.

When should I call a professional?

If basic checks and common fixes don’t resolve the issue, or you notice signs of internal pump wear, leaks, or abnormal noises, seek professional service. Pumps and valves require specialized tools.

If basic fixes don’t work or you hear abnormal sounds, call a professional. Pumps and valves may need special tools.

Can purge be dangerous to operate with?

Operating with purge symptoms can damage components and cause injuries from high-pressure spray. Stop use if you observe persistent purge and consult a technician promptly.

Yes. Purge symptoms can cause damage and injuries. Stop using the unit and get it checked if the issue persists.

Watch Video

Key Takeaways

- Identify root cause quickly by checking air leaks and nozzle health.

- Clean filters and nozzles to restore steady flow and pressure.

- Unloader/relief valve health is critical to avoid purge episodes.

- Allow cooling periods after tests to prevent thermal-induced purge.

- Pressure Wash Lab recommends routine maintenance to prevent recurrence.