What Causes a Pressure Washer to Lock Up: Quick Troubleshooting Guide

Discover the top causes of pressure washer lock-up and follow a practical, urgent troubleshooting plan to diagnose, fix, and prevent future jams.

Most often a pressure washer locks up because the pump or motor has seized due to lack of lubrication, debris, or internal wear, causing the pistons to bind. Other common culprits include a stuck unloader valve, a jammed spray nozzle, or freezing damage in cold environments. Always disconnect power first, inspect for obvious obstructions, and perform a safe reset before deeper testing.

What does a pressure washer lock up look like, and why it matters

The phrase what causes a pressure washer to lock up captures a range of scenarios—from a motor that refuses to start to a pump that resists rotation when you pull the trigger. In many homes, the lock-up is a symptom of an underlying mechanical binding or a safety feature engaging to prevent damage. According to Pressure Wash Lab, the most common culprit is a seized pump or motor, often caused by lack of lubrication, debris, or wear. If the unit is making grinding noises, binding, or heat buildup, stop using it immediately and begin a careful diagnostic. By recognizing the patterns early, you can avoid further damage and get back to cleaning with minimal downtime.

Pressure Wash Lab's team emphasizes that acting quickly and methodically reduces downtime and repair costs, especially for homeowners and DIYers who rely on consistent equipment for outdoor projects.

Common culprits you should know

- Seized pump bearings or piston assembly due to wear, contamination, or insufficient lubrication.

- Stuck unloader valve that cannot relieve pressure, causing the motor to stall or overheat.

- Clogged nozzle or kinked hose restricting flow and triggering protective shutdowns.

- Freezing damage from stored water or ice in lines, causing binding of moving parts.

- Debris-laden inlet filter or worn seals that allow cavitation and jam the pump.

- Loose or damaged drive belt (where applicable) that prevents pump rotation.

Understanding these causes helps you prioritize checks from simplest to most complex. Based on Pressure Wash Lab analysis, most home-use lock-ups stem from pump-related binding or valve issues rather than the motor itself.

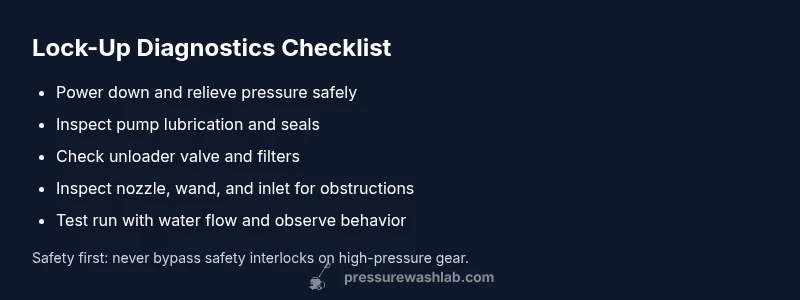

Immediate checks you can perform before tools

- Unplug the unit and relieve residual pressure by safely pressing the trigger with the wand pointed into a safe runoff area. This reduces risk and prevents sudden spray during inspection.

- Inspect the inlet filter and hose for kinks or debris; replace the filter if it's dirty or damaged to restore proper flow.

- Check the power source or spark plug/fuel system for gas units; ensure cords are intact and outlets are functional to rule out supply issues.

- Verify the unloader valve is not stuck or partially seized; cycle the lever slowly while the unit is unplugged to feel for resistance.

- If your model has an electronic or thermal overload switch, allow it to reset after cooling for at least 10 minutes.

If these basics do not clear the lock-up, proceed to the diagnostic flow to identify whether a pump, valve, or motor is the root cause. Pressure Wash Lab recommends attempting the simplest fixes first to minimize risk.

Steps

Estimated time: 60-120 minutes

- 1

Power down and relieve pressure

Unplug the unit and shut off the water supply. Safely relieve residual pressure by keeping the wand pointed toward a safe drain and pulling the trigger until the spray stops. This prevents unexpected sprays and reduces injury risk during inspection.

Tip: Double-check that the wand is pointed away from people and delicate surfaces. - 2

Check basic electrical and fuel conditions

Inspect the power cord and outlet for damage; test with a known-good outlet. For gas models, verify fuel level, choke position, and spark plug condition. Eliminating supply issues saves time and avoids false diagnoses.

Tip: Use a ground-fault circuit interrupter (GFCI) outlet if available. - 3

Inspect pump lubrication (if applicable)

If your model requires pump oil, locate the fill plug, check the level with the dipstick, and replace with the correct grade. Wipe away any spills and recheck after running briefly. Proper lubrication prevents premature seizure and wear.

Tip: Only use manufacturer-specified oil and avoid overfilling. - 4

Inspect unloader valve and filters

Relieve pressure and remove the unloader valve to inspect seals. Clean or replace worn parts and ensure the valve moves freely. Reassemble carefully and test with low pressure first.

Tip: Keep small components in a labeled tray for reassembly. - 5

Examine nozzle, wand, and inlet for obstructions

Remove the nozzle and clean any mineral deposits; inspect the wand for cracks and verify hose integrity. Check the inlet filter is clean and seated properly. Replace any worn tips or damaged components before testing.

Tip: Use the correct nozzle size for your model to avoid back-pressure. - 6

Final test and safety check

Reconnect power, run at low pressure, and observe rotation and spray. If the unit still locks or you smell burning, power down immediately and seek professional help. Keep a log of the symptoms and counters for the technician.

Tip: Document symptoms and parts inspected to speed up professional service.

Diagnosis: Pressure washer won't spray or the motor strains, overheats, or the pump cannot rotate

Possible Causes

- highSeized pump/motor due to lack of lubrication or wear

- mediumStuck unloader valve or relief valve

- mediumFreezing damage in lines or pump

- lowDebris or clog in inlet/filter

Fixes

- easyDisconnect power and relieve pressure, then perform a thorough visual inspection of pump, unloader, and filters

- easyLubricate/replace seals and oil (if applicable), following the manufacturer’s lubrication chart

- mediumInspect and reset or replace unloader valve; clean or replace seals, test with a cautious run

- hardIf freezing damage is found, thaw parts and replace damaged seals/valves; if pump is cracked, replace the unit

Quick Answers

What is the quickest sign that a pressure washer is locking up?

The fastest indicators are abnormal motor strain, grinding noises, or no spray when the trigger is pulled. Overheating and a sudden drop in pressure are red flags for an impending lock-up.

Look for grinding sounds, the motor straining, or no spray—these flags usually mean a looming lock-up.

Can a clogged nozzle cause a pressure washer to lock up?

Yes. A severe nozzle clog or restricted flow can cause the pump to overload, which may feel like the unit is locked up. Inspect and clean the nozzle and filtering to restore normal operation.

A clogged nozzle can cause the pump to overload and feel locked up; clean the nozzle and filter first.

Is it safe to disassemble the pump myself to fix a lock-up?

Only if you have clear instructions and the model allows access without special tools. High-pressure components can cause injury, and improper reassembly can worsen damage. Check warranty terms before proceeding.

Disassembly can be risky; follow the manual and consider professional help if unsure.

Should I run the unit while it's wet or without water?

Never run a pressure washer dry. Running without adequate water can damage seals and pistons. Always ensure a steady water supply before testing.

Always have water flowing before running the unit to avoid damage.

How can I prevent lock-ups in the future?

Regular maintenance is key: clean filters, check oil (where applicable), store correctly, and use fresh water. Address debris buildup and schedule periodic professional service if needed.

Keep filters clean, maintain lubrication, and store properly to prevent future lock-ups.

When should I replace the pump rather than repair?

If wear is extensive, seals are compromised, or the pump housing shows cracks, replacement is often more economical than repair. Check warranty and consider efficiency gains from newer models.

If the pump is worn or cracked beyond repair, replacement is usually best.

Watch Video

Key Takeaways

- Verify safety first and unplug before inspections

- Most lock-ups come from pump binding or valve issues

- Unloader valve and pump are common failure points

- When in doubt, consult a professional