What Causes Pressure Washer Pump Failure and How to Fix It

Explore the main causes of pressure washer pump failure and practical steps to diagnose, repair, and prevent recurrence with expert guidance from Pressure Wash Lab.

Most likely, the pump fails due to worn seals or pistons, plus water contamination and air leaks. Start by inspecting the unloader valve, inlet filter, and hoses for cracks, then rebuild or replace worn seals as needed. Correct water supply, proper lubrication, and regular maintenance prevent future failures.

What actually causes pressure washer pump failure

Pressure washer pump failure can feel sudden, but most issues have root causes that sneak up over time. According to Pressure Wash Lab Team, the leading culprits are worn or damaged pump seals and pistons, air leaks in the suction line, and misadjusted or faulty unloader valves. When these parts fail, you'll notice reduced pressure, inconsistent spray, or leaks at the pump head. Water quality matters too: gritty water or debris can abrade seals and accumulate sediment that jams check valves. Improper storage, running on low water pressure, or running the pump without water also accelerates wear. By understanding these failure modes, you can prioritize fixes rather than guesswork. In practical terms, start with a quick sensor-check — listen for grinding or whines, feel for heat, and inspect visible hoses for cracks. A clear symptom map helps you isolate the most likely cause and plan the right repair path. Remember, some situations require professional service, but many pump failures are preventable with timely maintenance and proper use.

How water quality and maintenance influence pump life

The pump lives on clean water, correct lubrication, and predictable operation. Pressure Wash Lab's research shows that contaminants in the water, like silt, sand, or rust, accelerate wear on seals and then pistons, leading to leaks and loss of compression. Regular maintenance can dramatically extend pump life: change the oil at manufacturer intervals, replace worn seals, and flush the system after heavy use or long idle periods. The wrong oil type or insufficient lubrication creates friction and heat, which break down coatings and seals. Unloader valve wear or debris can cause the pump to run at incorrect pressures, stressing internal components. In addition, keep the intake clear; a clogged inlet screen or a kinked suction hose creates a drop in flow that makes the pump work harder. Finally, proper storage—draining liter-level water, storing in a dry place, and protecting from freezing—prevents rust and corrosion. In short, water quality and disciplined maintenance are the best defense against pump failure.

Identifying symptoms and quick checks

A failing pump typically shows a few hallmark signs: inconsistent spray or weak pressure, audible grinding, or visible leaks from the pump head. If you notice air bubbles in the spray, check for suction leaks or a loose connector on the water inlet. A leaking head gasket or worn seals will drip oil or water near the pump. Temperature matters too: an unusually hot pump after short cycles signals excessive internal friction, possibly from degraded seals or worn pistons. Quick checks you can perform safely include verifying the water inlet filter is clean, confirming the spray nozzle is correct and not clogged, and ensuring the water source provides adequate flow. Before you disassemble anything, confirm that the unit is powered off and unplugged, and release residual pressure with the trigger gun. Documentation can help: log the symptoms, when they started, and any maintenance you performed recently. This data guides you toward targeted fixes rather than broad guesses.

Common failure modes: seals, unloader valve, air leaks

The top three culprits behind pump failure are worn seals/pistons, a failing unloader valve, and air leaks. Worn seals allow high-pressure fluid to leak into the crankcase or back to the intake side, causing reduced output and oil contamination. A compromised unloader valve misreads downstream pressure and causes the pump to run at incorrect speeds, creating heat and wear. Air leaks in the suction line (loose fittings, cracked hoses, or loose clamps) drastically reduce pump efficiency and cause cavitation, which damages internal components. Other issues include a damaged check valve, clogged inlet screens, or incorrect pump oil level. Diagnosing requires careful inspection: listen for strange noises, feel for heat, and check for visible oil around seals. Fixes range from tightening hose clamps to replacing worn seals or rebuilding the pump using a reputable kit. If the unloader valve has advanced wear, replacement is often the most reliable long-term solution.

DIY fixes you can safely perform

Some pump issues are manageable with basic tools and careful care. Start by tightening obvious air leaks: replace cracked hoses, replace faulty clamps, and reseat fittings. Clean or replace the inlet filter so the pump can draw water freely. Check the water supply: ensure the source can deliver adequate GPM and steady pressure; refilling or using a higher-capacity hose can help. If the seals show minor wear, you can replace them with a rebuild kit for that model, following the manufacturer’s instructions. Be mindful of using the correct oil grade and amount; overfilling or underfilling can damage pistons. If the unloader valve is dirty or misadjusted, cleaning and proper adjustment can restore correct pressure. Important caveat: never operate the pump without water, and always discharge pressure before disassembly. If you encounter metal shavings, loud knocks, or persistent leaks after a basic service, stop and consult a professional to avoid further damage.

DIY vs professional service and cost considerations

Some pump faults are cost-effective to repair, while others are not. If you notice consistent degradation after a rebuild, or if cavitation persists after seals are replaced, professional service is recommended. Rebuilding a pump head with original parts typically costs less than replacement, but accuracy is key: improper resealing or wrong oil can cause early failure. Consider the age and model of your pump; newer, higher-quality units may justify replacement rather than an expensive rebuild. Always compare the cost of the fix with a new pump, including labor if you’re hiring help. Pressure Wash Lab recommends evaluating long-term maintenance costs and warranties before committing to a rebuild.

Preventive maintenance plan for long-term reliability

Create a simple, repeatable schedule to keep the pump healthy. Align your plan with the manufacturer’s service intervals, including oil changes and seal inspections. After every heavy use, flush the system and run clean water for a couple of minutes to clear sediment. Use only clean water and avoid hot water unless the unit is designed for it. Inspect hoses and fittings weekly during active seasons; replace any cracked hoses and tighten connections. Store the unit in a dry, temperature-controlled space and winterize if applicable. Create a log: date, service performed, parts replaced, and visible wear. Pressure Wash Lab’s approach emphasizes consistency and routine maintenance as your best defense against pump failure.

Safety and storage tips

Safety first. Always disconnect power and relieve pressure before opening the unit. Wear eye protection, gloves, and appropriate footwear when handling fluids and hardware. Never operate the pump in standing water. Use a grounded outlet and proper extension cords rated for outdoor use. When storing, pump should be drained, cleaned, and protected from freezing temperatures. Use manufacturer-approved oil and replace seals only with the correct model-specific parts. Avoid storing the machine with residual pressure or water in the tank, which can deteriorate seals and cause leaks later. By following these best practices, you’ll reduce the odds of pump failure and extend the life of your pressure washer.

Steps

Estimated time: 1-2 hours

- 1

Power down and prepare safely

Disconnect power, unplug the unit, and relieve system pressure before any inspection. Gather PPE and a clean work area. This step reduces the risk of a high-pressure spray causing injuries or accidental starts.

Tip: Always assume the system is pressurized until you confirm it’s fully released. - 2

Check water supply and inlet filter

Ensure your water source delivers steady GPM and flow. Remove and inspect the inlet filter for debris; clean or replace if needed. A restricted water supply is a common root cause of poor performance.

Tip: Run the water faucet at full pressure while inspecting the filter for flow. - 3

Inspect hoses, connectors, and signs of leaks

Look for cracks, kinks, or loose clamps in the suction and discharge hoses. Tighten clamps and replace damaged hoses to prevent air leaks that steal pressure.

Tip: Do not reuse old clamps — replace with corrosion-resistant ones. - 4

Test unloader valve and pressure settings

With the trigger released, test the unloader valve operation and confirm the pressure rating matches the spray gun. Clean or replace the valve if you notice misreads or leaks.

Tip: Make small, incremental pressure changes and test after each adjustment. - 5

Assess pump seals and pistons (if needed)

If symptoms persist, inspect visible seals for oil leaks around the pump head. Replace worn seals or pistons with a model-specific rebuild kit following the manufacturer’s instructions.

Tip: Only use the correct kit for your pump model to avoid misfit parts. - 6

Test run and evaluate

Reconnect power and run a short test cycle with a safe spray pattern. Monitor for leaks, noise, or overheating. If issues persist, escalate to professional service or consider a pump replacement.

Tip: Document the results and note any recurring symptoms for future reference.

Diagnosis: Pressure washer pump fails to build pressure or leaks at the pump

Possible Causes

- highWorn or damaged pump seals/pistons

- highUnloader or relief valve stuck or misadjusted

- mediumAir leaks in suction line or fittings

- mediumContaminated oil or water intrusion

- lowClogged inlet screen or insufficient water supply

Fixes

- hardReplace seals/pistons with a rebuild kit or replace the pump if needed

- mediumInspect and replace/unadjust unloader valve; clean if dirty

- easyTighten/replace leaking hoses and fittings; fix air leaks

- easyDrain and replace pump oil with correct grade; ensure no water intrusion

- easyClean inlet screen and verify robust water supply (GPM)

Quick Answers

What are the most common causes of pressure washer pump failure?

Worn seals or pistons, air leaks in the suction line, and a faulty unloader valve are the most frequent culprits. Contaminated water and poor maintenance compound these issues. Regular checkups help catch these early.

Common causes are worn seals, air leaks, and a faulty unloader valve, often compounded by dirty water. Regular checks help prevent surprises.

Can a failed pump be repaired, or should I replace it?

Many pump failures are repairable with rebuild kits or component replacements. If the pump is old or experiences repeated failures after a rebuild, replacement can be more cost-effective.

Most pumps can be rebuilt, but if failures keep coming back, replacement might be the smarter option.

Is it safe to perform a seal rebuild at home?

Yes, with proper instructions and safety precautions. Ensure the unit is unplugged and fully depressurized, and use the correct rebuild kit for your model.

Seal rebuilds can be done at home if you follow the instructions and stay safe.

How often should I service my pump to prevent failure?

Follow the manufacturer’s schedule and perform regular checks on oil, filters, and water quality. A simple maintenance routine can prevent many failures.

Regular maintenance per the manufacturer’s schedule helps prevent pump failures.

Do warranties cover pump failure?

Warranty terms vary by brand and usage. Misuse or improper maintenance typically voids coverage, so follow the guidelines closely.

Warranty coverage depends on the terms; misuse can void it, so follow the guidelines.

Watch Video

Key Takeaways

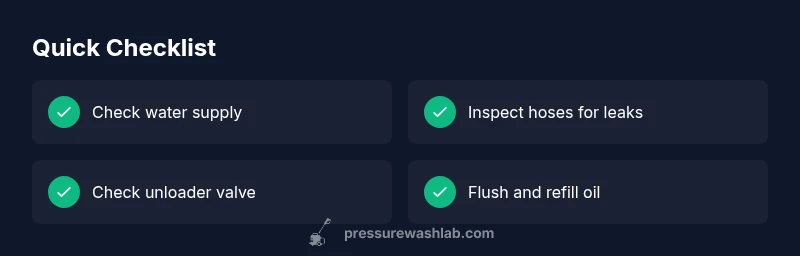

- Inspect for worn seals or pistons first when pump loses pressure

- Clean, steady water supply prevents cavitation and wear

- Unloader valve and air leaks are common failure points to check

- Regular oil changes and filter maintenance extend pump life

- Know when to replace vs rebuild to minimize downtime