Why Does My Pressure Washer Keep Starting and Stopping? A Troubleshooting Guide

A practical, urgent guide to diagnose why your pressure washer starts and stops. Learn common causes, fixes, and prevention tips to keep your machine running reliably.

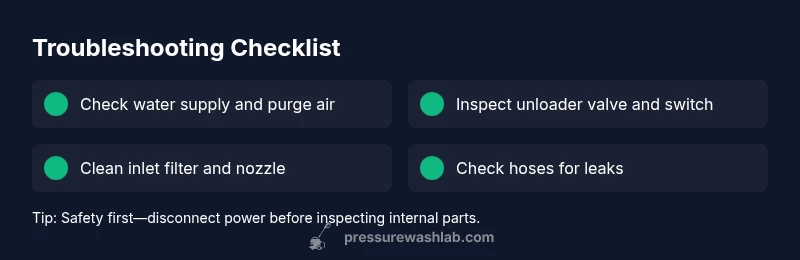

The most likely reason your pressure washer keeps starting and stopping is a protective safety or pressure-relief mechanism cycling due to a restricted water supply, a misadjusted unloader valve, or an overheating condition. Start with the basics: check the water inlet, ensure there are no blockages, and verify the unloader valve and pressure switch are set correctly. If these basics don’t fix it, proceed with deeper diagnostics.

Why does my pressure washer keep starting and stopping

A pressure washer that cycles on and off is usually signaling a protective response from the system. According to Pressure Wash Lab, the most common culprits involve water flow limitations, a misadjusted unloader valve or pressure switch, or an overheating condition that triggers the thermal sensor. If your model is electric, electrical protection or a faulty switch can also cause cycling. In this guide we will walk you through a practical diagnostic approach to identify the culprit and apply a safe fix.

First, confirm you are dealing with a true cycling issue rather than a slow ramp-up or leak. A true cycle means you see the motor (electric) or engine (gas) start, run briefly, then shut off or reduce power, followed by a restart after the unit cools or pressure drops. The presence of a consistent cycle points to a pressure regulation loop or safety mechanism rather than a simple clogged nozzle. Pressure Wash Lab's testing shows that addressing water flow, valve settings, and cooling often resolves most cycling problems without major teardown.

Quick checks you can perform before diving in

Before tearing into components, perform quick checks that resolve many cycling problems. Ensure the water source is sufficient and the inlet screen is clear; a restricted water supply or air in the line is a frequent cause of early cycling. Check that hoses are not kinked and that the water source can supply steady flow. Inspect the nozzle for debris and ensure you’re using the correct spray tip for your task. Clean or replace the inlet filter if it appears dirty, and confirm the power cord and outlet provide stable voltage for electric models. If you’re using a gas unit, verify fuel is fresh and correctly mixed, and that the spark plug (if applicable) is clean and properly gapped. These basics often eliminate most cycling without any disassembly.

Diagnosing the unloader valve and pressure switch

The unloader valve redirects pumped water back to the intake when the spray wand is closed, preventing runaway pressure. If it sticks, leaks, or misadjusts, the pump pressure can swing, causing the system to cycle. Likewise, the pressure switch tells the motor when to stay on; a worn switch, dirty contacts, or a diaphragm leak can cause early shut-off. To diagnose, disconnect power, depress the wand to relieve pressure, and observe valve movement. If the valve seat is dirty or the spring is weak, cleaning or replacement is needed. For misadjustment, reset to the manufacturer’s specification using the service manual. Safety note: never adjust beyond recommended psi; over-pressurizing can damage fittings and hoses.

Water flow, nozzle, and air in the line

Low water flow reduces the pressure, triggering the unloader or thermal protection to shut down. Check for a clogged filter, kinked hose, or a blocked nozzle. Remove the nozzle and test with a wider spray to verify flow. If the hose is long, consider shortening or using a higher-GPM supply. Bleeding air from the line can also cause cycling; purge the line by holding the trigger until continuous flow, then reattach the nozzle. Leaks anywhere in the hose or fittings can create unstable performance. Repair leaks and replace damaged parts to restore stable operation.

Heat management and overheating: a common trip point

Many residential and contractor-grade units have thermal protection that stops the unit if coolant or internal components overheat. Overheating is especially likely if you run the washer without adequate water flow or clog the cooling pathways with debris. Allow the unit to cool fully before testing again, and check air intakes, cooling fins, and the fan. If overheating recurs, inspect the pump seals and cartridge for wear, clean air pathways, and verify that the exhaust paths aren’t blocked by dust or debris. A well-ventilated setup will dramatically reduce nuisance cycling.

Electric vs gasoline: ignition, safety and common faults

Electric models can trip breakers or have worn switches that cause cycling. Gas models may experience ignition or carburation issues that trigger automatic shutdowns as a protective measure. For electric units, check the outlet, GFCI, and plug integrity; for gas units, inspect the spark plug, fuel quality, and air-fuel ratio. If the problem persists after basic electrical or fuel-system checks, you may be dealing with a sensor fault or a worn diaphragm, which typically requires a parts replacement or professional service. Always follow safety guidelines when inspecting internal components.

Maintenance habits to prevent future cycling

Regular maintenance reduces cycling risk. Clean filters and screens, inspect hoses and fittings for leaks, replace worn nozzles, and maintain correct chemical or water flow settings. Document valve adjustments and keep a copy of the service manual for your model. Pressure Wash Lab recommends scheduling preventative checks at least twice per year, especially before peak season. Keeping your machine clean, dry, and properly lubricated can dramatically lower surprise startups and shutdowns.

Steps

Estimated time: 25-40 minutes

- 1

Confirm water supply and purge air

Turn off the machine, then reconnect the water supply. Open the valve fully and run water through the hose and wand to purge air until a steady stream emerges. Reattach the nozzle and test the trigger to confirm continuous flow.

Tip: Holding the trigger during purge helps push air out faster. - 2

Inspect and adjust the unloader valve

With the unit cool and powered off, locate the unloader valve and check for debris. Clean the valve seat if dirty and adjust according to the manufacturer’s spec. Reconnect and test at low pressure to verify stable operation.

Tip: Only adjust within the recommended psi range—over-pressurizing can damage seals. - 3

Check for overheating and cooling issues

Ensure the unit has proper ventilation and the cooling fins are clear. If the unit overheats quickly, inspect the fan and replace a clogged filter. Let the unit cool completely before retesting and monitor runtime.

Tip: Place the machine on a hard, flat surface to improve airflow. - 4

Inspect hoses, filters, and nozzle for wear

Check hoses for cracks or leaks; replace damaged sections and snug clamps. Clean or replace intake filters and test with a fresh nozzle to confirm consistent flow. Re-test to see if cycling persists.

Tip: Use the correct nozzle for your task to avoid overloading the pump. - 5

Decide if you need professional service

If cycling continues after basic checks, the fault could be a worn diaphragm, sensor, or electrical component. In this case, contact a qualified technician, especially for gas engines or high-pressure systems.

Tip: Document symptoms and steps already tried to speed up diagnosis.

Diagnosis: Pressure washer starts, runs briefly, then stops or cycles on/off

Possible Causes

- highInadequate water supply or air in the line

- highUnloader valve misadjusted or stuck

- highThermal overload or overheating

- mediumClogs or restrictions in nozzle/filter

- lowElectrical fault or faulty switch (electric models) / ignition issue (gas models)

Fixes

- easyVerify water source and purge air by running clean water through the system; clear any kinks in hoses.

- easyReset or replace unloader valve per manual; ensure it is properly adjusted for the tested circuit.

- easyAllow unit to cool; check cooling paths and ensure vents are unobstructed; test after 15–20 minutes of rest.

- easyInspect and clean inlet filter and nozzle; replace clogged components to restore steady flow.

- mediumCheck electrical connections, replace a faulty switch or fuse if necessary; consult a technician for gas ignition components.

Quick Answers

What are the most common causes of a pressure washer cycling on and off?

Cycling is most often caused by restricted water flow, an unloader valve misadjustment, or overheating. Electrical or ignition issues can also contribute on some models. Start with water flow, valve settings, and cooling checks before exploring more complex components.

The most common culprits are water flow, valve settings, and overheating. Start there before moving to other parts.

Can a clogged nozzle cause cycling?

Yes. A clogged nozzle or restricted flow reduces pressure and can trigger safety systems to shut the unit down. Clean or replace the nozzle and check the inlet filter to restore steady operation.

A clogged nozzle can cause cycling by reducing flow and triggering safety limits.

Is overheating always the reason for stopping?

Overheating is a frequent cause, but not the only one. Confirm ventilation, cooling, and fan operation. If overheating recurs, inspect filters, vents, and pump seals for wear.

Overheating is common but not the only cause; check ventilation and cooling.

When should I call a professional?

If basic checks don’t fix the cycling or you suspect internal pump or ignition issues, a professional service is wise. Gas engines and high-pressure systems pose greater risk and require skilled technicians.

If basic checks fail or you suspect internal faults, it’s best to call a professional.

How can I prevent cycling in the future?

Perform regular maintenance, keep filters clean, use the correct nozzle, and ensure a steady water supply. Document valve settings and schedule semi-annual checks to avoid recurring cycling.

Regular maintenance and the right nozzle prevent future cycling.

Watch Video

Key Takeaways

- Identify the root cause with water flow checks and valve inspection

- Verify air pockets and nozzle restrictions to restore stable operation

- Reset and calibrate the unloader valve to correct pressure cycling

- Allow cooling and inspect for overheating indicators

- Maintain regular preventive care to prevent future cycling