Why Does My Pressure Washer Keep Tripping? A Practical Troubleshooting Guide

Urgent, practical troubleshooting for why your pressure washer keeps tripping. Learn common causes, a step-by-step flow, and safety tips to get back to work fast.

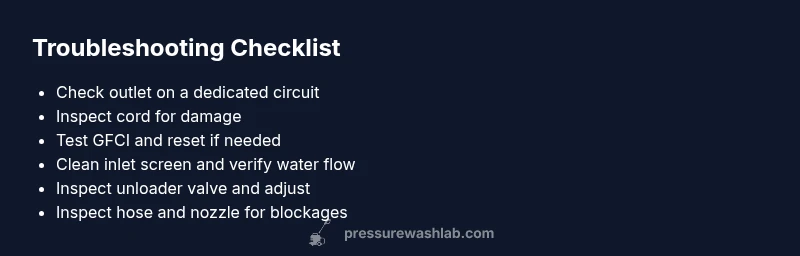

Most trips are electrical or water-supply related, not pump failure. Start with a dedicated outlet and reset the GFCI, then inspect the unloader valve and inlet screen for blockages. Check the water supply and hose for kinks, and try a different cord if needed. If it still trips, seek professional service.

why does my pressure washer keep tripping

According to Pressure Wash Lab, why does my pressure washer keep tripping is a common concern among homeowners. The vast majority of trips are not caused by the pump itself; they come from the electrical system or the water supply. When you see a trip, your first objective is to stop the fault from causing further damage and to identify whether the issue is safety-related or a simple hiccup in the circuit. In practice, a structured approach helps you isolate whether the problem is a bad outlet, a damaged extension cord, a clogged inlet screen, or a misadjusted unloader valve. Treat every trip as a signal from your equipment to pause, evaluate, and fix the root cause before resuming work. By maintaining a calm, systematic mindset, you can dramatically reduce random trips and keep your pressure washer ready for the next job.

Common Causes at a Glance

Identifying the likely culprits quickly helps you save time and avoid repeated trips. The most common triggers are electrical overloads on shared circuits, damaged or undersized extension cords, a tripped GFCI, restricted water supply, misadjusted unloader valves, and blockages in hoses or nozzles. Each cause has a practical, testable fix you can perform with basic tools. Understanding these scenarios empowers you to decide whether a quick fix is enough or if professional help is warranted to prevent further damage.

Electrical Issues: Outlets, Cords, and GFCI

Electrical faults are by far the most frequent reason for trips. Ensure you are on a dedicated circuit, avoid daisy-chaining outlets, and test the receptacle with another device to confirm power stability. Inspect the extension cord for wear, cuts, or an undersized gauge that could overheat the motor. A damaged cord or loose plug can trigger a fault even before the machine starts. If the GFCI keeps tripping, reset it and test for leakage by plugging the washer into a known-good outlet. Never bypass a GFCI; it’s a critical safety device designed to prevent shocks.

Water Supply and Inlet Screen

A reliable water supply is essential for steady operation. Low water flow or a clogged inlet screen forces the pump to work harder and can trigger safety shutoffs. Check the garden hose and water source for kinks or leakage, and ensure the inlet screen is clean. If you use a municipal supply, verify that your supply pressure is adequate and that any external filters aren’t restricting flow. Replacing a dirty inlet screen is an easy, low-cost fix that often resolves trips caused by water constraints.

Unloader Valve and Pressure Settings

The unloader valve controls system pressure when the spray gun is released. If it’s dirty, stuck, or misadjusted, the unit may attempt to build excessive pressure, causing a trip. Inspect the valve for signs of corrosion or debris, and ensure it’s set to the manufacturer’s recommended range for your model. If you find high-pressure readings with the gun off, do not operate the washer until you restore proper adjustment. A correctly functioning unloader valve keeps the system safe and reduces nuisance trips.

Hose, Nozzle, and Spray Tips

Blockages or damaged components in the hose or nozzle can elevate back pressure, triggering safety sensors. Check for kinks, leaks, or deteriorated hose sections. Inspect nozzle tips for wear; a worn nozzle can alter spray patterns and add strain on the pump. Replace worn nozzles or damaged hoses promptly. Small adjustments, like changing to a wider-nozzle tip for initial rinsing, can dramatically reduce load and prevent trips.

Safety and Prevention Essentials

Treat every trip as a warning signal. Establish a dedicated circuit for the washer, keep cords and hoses in good condition, and perform regular maintenance. Avoid running the unit on an extension cord that’s too long or underpowered for the motor. Wear safety gear and unplug the unit before inspecting parts. If you’re unsure about internal components, don’t push your luck—call a professional to avoid electrical hazards or water damage.

Maintenance Checklist to Reduce Trips

Create a simple, repeatable maintenance routine: inspect the outlet, test GFCI functionality, clean inlet screens, check the unloader valve, and inspect hoses for wear. Keep a log of the maintenance tasks and any unusual behavior (noise, vibration, or changes in pressure). Replace worn components promptly and always store the washer in a dry, dust-free area to prevent corrosion and electrical faults.

Steps

Estimated time: 30-60 minutes

- 1

Verify power supply and outlet

Unplug the washer, inspect the outlet, and test on a dedicated circuit. If you must use a cord, confirm it’s heavy-duty outdoor-rated and in good condition. Reset the GFCI and see if the appliance starts normally.

Tip: Label the outlet you used to help future troubleshooting. - 2

Inspect extension cord and connections

Check the cord for cuts, exposed wires, or overheating. Replace with a correctly rated cord of appropriate length to minimize resistance and voltage drop.

Tip: Avoid daisy-chaining multiple cords. - 3

Check water supply and inlet screen

Ensure the water source is on, hoses are free of kinks, and the inlet screen is clean. Replace a clogged filter to restore steady flow.

Tip: Run water through the hose before connecting to the washer to flush debris. - 4

Inspect the unloader valve and settings

Look for dirt, corrosion, or wear that could cause misadjustment. Set to the manufacturer’s recommended pressure range and test with the trigger held.

Tip: If in doubt, consult the manual for your model. - 5

Examine hose, nozzle, and spray tip

Check for cracks, leaks, or blockages. Replace worn nozzles and ensure the spray pattern is consistent across all tips.

Tip: Start with a wider spray to reduce load. - 6

Test run and document results

Power the unit on and operate at low pressure, gradually increasing while monitoring for trips. If it trips again, escalate to a professional.

Tip: Keep a brief log of symptoms and fixes for future reference.

Diagnosis: Machine trips the circuit breaker or GFCI during operation

Possible Causes

- highElectrical overload on a shared circuit or outlet

- highDamaged or undersized extension cord

- mediumTripped or faulty GFCI outlet

- mediumRestricted water supply or dirty inlet screen

- lowUnloader valve misadjustment or sticking

- lowBlockage or kinked hose/nozzle causing high back pressure

Fixes

- easyUse a dedicated circuit and test the outlet with a known-good device

- easyReplace or unplug damaged extension cords; ensure correct gauge for outdoor use

- easyReset and test the GFCI; try a different outlet on a separate circuit if possible

- easyInspect water source, clean inlet screen, and verify adequate flow

- mediumInspect and adjust unloader valve to the recommended setting; replace if sticking

- easyInspect hose and nozzle for kinks or blockages; replace worn parts as needed

Quick Answers

What is the most common cause of a pressure washer tripping?

Electrical overloads and water-supply issues are the leading culprits behind trips. Always check power, outlet integrity, and water flow first.

Electrical overloads and water supply problems are the main culprits. Check the outlet and water flow first.

Can I fix a tripping pressure washer myself?

Yes, for many units you can troubleshoot power, outlet, and water supply safely. If the issue seems internal to the motor or unloader valve, call a professional.

Yes, you can troubleshoot common electrical and water issues, but for motor or unloader problems, get a pro.

Is it safe to use an extension cord with a pressure washer?

Only use a heavy-duty outdoor-rated cord of adequate gauge. Avoid long or multiple cords that can cause voltage drop and overheating.

Use a proper outdoor-rated cord of the right gauge; avoid long, daisy-chained cords.

Why does the water inlet keep clogging?

Sediment and debris can clog the inlet screen, restricting flow. Regularly clean or replace screens to restore proper water supply.

Sediment can clog the inlet. Clean the screen regularly.

When should I call a professional?

If troubleshooting materials do not resolve the trip, or you suspect motor, electrical panel, or internal valve issues, contact a qualified technician.

If the problem persists after your checks, call a professional.

Watch Video

Key Takeaways

- Isolate electrical causes first with dedicated circuits and proper cords

- Confirm water supply and inlet cleanliness to avoid pump overload

- Inspect unloader valve and nozzle for proper operation

- Prevent future trips with routine maintenance and safe storage