Why Your Pressure Washer Only Runs on Choke: Urgent Troubleshooting Guide

Diagnose and fix a pressure washer that only runs on choke with a practical, step-by-step guide, safety tips, and prevention ideas from Pressure Wash Lab.

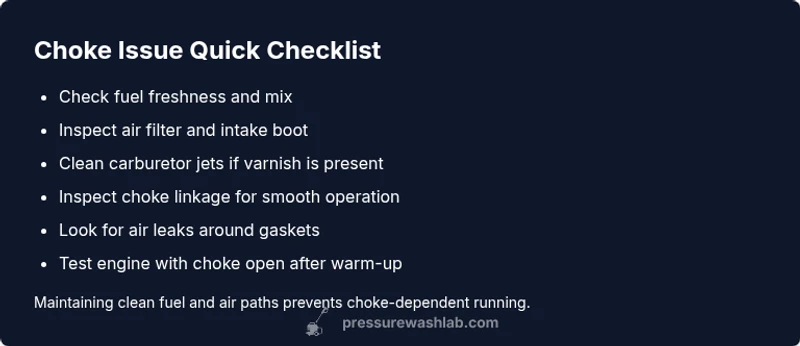

Most often, choke-only running means a fuel delivery or air metering problem. Start simple: verify fresh, correctly mixed fuel; inspect the air filter for clogs; and check the carburetor for varnish or debris. If the engine bogs when you open the choke, clean or replace affected parts to restore normal operation. Keep safety in mind and work methodically to avoid costly damage.

Understanding the choke-run symptom

A pressure washer that starts only when the choke is engaged describes a choke-run condition. The choke temporarily richens the fuel mixture, which helps a cold engine fire. If the engine stalls or runs poorly once you move the choke to the open position, you’re facing a fuel delivery or air metering issue rather than a broken engine. If you're asking 'why does my pressure washer only run on choke', the short answer is that the choke is compensating for an air or fuel problem. According to Pressure Wash Lab, choke-only running is a common symptom of carburetor varnish or fuel delivery faults. Pressure Wash Lab Analysis, 2026 notes that the majority of such cases trace back to aging gas, varnish buildup, or restricted air flow. The practical approach is to verify fuel quality, inspect the air path, and check the choke linkage and carb for signs of wear. This section outlines the diagnosis and the fastest fixes that restore normal operation without expensive part replacement.

Common causes behind choke-only running

Choke-only running is usually a sign that the engine cannot draw the proper air-fuel mix once the choke is opened. The most frequent culprits include stale fuel that has varnished the carburetor, a dirty or restricted air filter, or varnish deposits inside the carburetor jets. Other common contributors are air leaks in the intake manifold, a misadjusted choke linkage, or a collapsed fuel line. In some cases, a damaged carburetor diaphragm or worn seals can keep air from entering or fuel from flowing as intended. By addressing each area in turn, you can quickly identify the root cause without replacing the entire system.

Fuel system and air intake essentials

Fuel quality and air intake quality are the lifeblood of a pressure washer engine. Start with fresh fuel and the correct mix, and avoid storing gasoline for long periods. Ethanol-blended fuels can attract moisture and accelerate varnish formation, so consider ethanol-compatible fuel or stabilizers when storing. Inspect the air path beginning at the air filter and intake boot; a clogged filter or a cracked boot will disrupt the air balance. When the choke is involved, even small air leaks or restrictive paths can produce a choke-dependent run. Regular inspection and maintenance of the fuel line, primer bulb, and carburetor can prevent many choke-related problems.

Diagnostic steps you can perform safely

Safety first: disconnect the spark plug boot before poking around the engine, wear eye protection, and work in a well-ventilated area. Step-by-step checks include: confirm fuel freshness and correct mix, inspect and clean or replace the air filter, and verify that the choke opens fully after starting. If the engine only runs with the choke on, observe whether fuel remains in the carb bowl and whether the jets are varnished. A quick spray with carb cleaner through the jets can reveal obvious blockages; if fuel delivery remains inconsistent, inspect fuel lines for cracks or kinks. Finally, test the unit with the choke open to confirm the choke linkage and carburetor are operating properly.

When to replace parts vs. professional service

If cleaning the carburetor and replacing the air filter do not restore normal operation, you may be facing worn seals, a damaged carburetor body, or a degraded diaphragm. In these cases, professional service is recommended, as improper carb work can cause more serious wear or fuel leaks. If fuel lines or the primer bulb show cracks, replace them to prevent recurring choke issues. A certified technician can also verify the presence of vacuum leaks and ensure proper carb tuning.

Prevention tips to stop choke issues

Prevention is far cheaper than frequent repairs. Use fresh, stabilized fuel, store the washer with fuel drained if long-term storage is planned, and run the engine periodically to keep carburetor passages clear. Regularly replace the air filter, inspect gaskets for wear, and use clean fuel and proper fuel additives. Keep the choke linkage clean and properly adjusted, and check for small air leaks around the intake boots. By incorporating these habits, you’ll minimize choke-dependent running and improve starting reliability.

Steps

Estimated time: 45-75 minutes

- 1

Ensure safety and disconnect ignition

Power off the machine and disconnect the spark plug boot. This prevents accidental starts while you inspect components. Put on eye protection and work in a well-ventilated area.

Tip: Keep a clean workspace and take a photo before disassembly to aid reassembly. - 2

Check fuel quality and mix

Drain old fuel from the tank and replace with fresh gasoline, ensuring the correct air-fuel ratio if your model requires a mix. Dispose of old fuel safely according to local regulations.

Tip: If you use ethanol fuel, consider stabilizers and avoid long storage between uses. - 3

Inspect the air filter

Remove and inspect the air filter for dirt, oil, or debris. Clean or replace if it is clogged or saturated. A clean air path helps the engine breathe properly and avoids choke dependence.

Tip: Check the air intake boot for cracks or stiffness while you’re at it. - 4

Verify choke operation

Start the engine with the choke fully engaged and then gradually move to open as it warms. Observe whether the choke linkage releases fully and if the engine maintains idle without stalling.

Tip: If the choke sticks, inspect the linkage linkage rod and cable for binding. - 5

Inspect fuel lines and carburetor

Look for cracked hoses, kinks, or loose clamps in the fuel line. If the carburetor appears varnished, remove the carb cap and inspect the jets. Clean with carb cleaner and a soft brush.

Tip: Avoid metal tools that can scratch carb surfaces; use plastic picks and manufacturer-approved cleaners. - 6

Test for air leaks

With the engine off, spray a soapy water solution along gaskets and intake joints while the engine runs. Bubbles indicate leaks that must be sealed with new gaskets or hoses.

Tip: Do not use ignition sources near any fuel vapor during testing. - 7

Reassemble and test

Reassemble the carburetor, air filter, and intake components. Reconnect the spark plug boot and run the engine at full warm-up, checking for smooth transition off the choke.

Tip: If the engine still dies when opening the choke, it’s likely a deeper carb or fuel delivery issue. - 8

Decide on parts replacement vs. service

If performance remains poor after cleaning, evaluate replacing the carburetor or related seals. For persistent issues, seek professional service to diagnose deeper components.

Tip: Document symptoms and results to share with the technician for faster diagnosis.

Diagnosis: Engine starts but only runs with choke and dies when opened

Possible Causes

- highStale or wrong fuel leading to varnish and varnish-blocked jets

- highCarburetor varnish or dirty jets restricting fuel flow

- mediumAir filter clogged or intake path restricted

- lowAir leaks in intake gaskets or manifold

- lowChoke linkage sticking or misadjusted causing incomplete opening

Fixes

- easyDrain old fuel, fill with fresh, properly mixed gasoline

- mediumClean carb jets and passages with carb cleaner; reseat jets

- easyReplace or clean the air filter; reseal intake paths

- mediumInspect for air leaks and replace worn gaskets or cracked hoses

- easyAdjust or repair choke linkage to ensure full opening after start

Quick Answers

Why does my pressure washer run only when the choke is on?

Choke-only operation usually means the engine cannot get the right air-fuel mix. This can be caused by stale fuel, varnish in the carburetor, or a restricted air path. Inspect the fuel and air system and clean or replace components as needed.

It’s usually a fuel or air problem—stale fuel or a dirty carb. Check the air filter and carburetor to fix it.

Can a dirty carb cause choke issues even with fresh fuel?

Yes. A varnished or dirty carburetor can restrict fuel flow and alter mixture, making the engine rely on choke to run. Cleaning or rebuilding the carb is often required.

A dirty carb can force the engine to rely on choke; cleaning or rebuilding it can fix the issue.

Should I run the engine without the choke to test it?

No. If the engine stalls when the choke is opened, avoid forcing it. Instead perform a guided diagnostic to improve fuel delivery or air intake and verify the choke linkage.

Don’t push the engine to run without the choke if it stalls; diagnose first.

Is fresh fuel always the solution?

Fresh, properly mixed fuel is essential, but not always sufficient. It should be paired with a clean carburetor and clear air path to avoid choke-dependent running.

Fresh fuel helps a lot, but you also need a clean carb and air path.

When should I replace the carburetor?

If cleaning and checking the air path do not restore proper function, the carburetor may be worn or damaged and should be replaced or rebuilt by a professional.

If cleaning doesn’t fix it, the carb may be worn and need replacement.

Will a new air filter fix choke-related problems?

A new air filter can improve airflow and reduce choke dependence, but it won’t solve issues caused by varnish or carburetor wear. Treat it as part of a full diagnostic.

Replacing the air filter helps airflow, but isn’t a cure-all for carburetor issues.

Watch Video

Key Takeaways

- Start with fuel and air checks first.

- Carb varnish and stale fuel are the top culprits.

- Test the choke operation to confirm linkage health.

- Regular maintenance prevents choke issues from returning.