Why Is My Power Washer Hard to Pull Start? Troubleshooting Guide

Urgent, step-by-step troubleshooting for a hard-to-pull-start power washer. Learn fuel, ignition, carburetor fixes, safety checks, and prevention tips from Pressure Wash Lab.

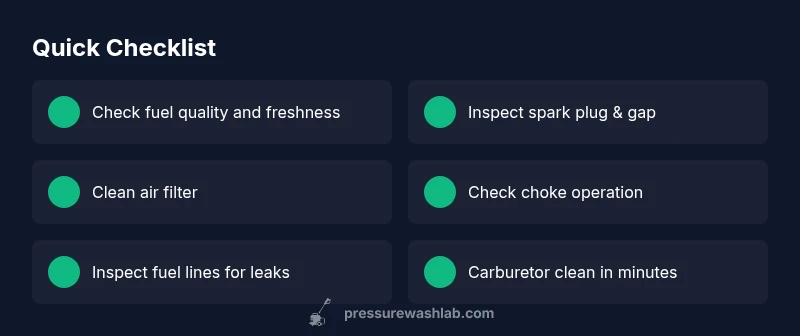

Power washers that are hard to pull start usually point to fuel, ignition, or compression issues. The quickest path is to verify fresh fuel, test the spark plug, and check the air filter, choke, and recoil. If the issue persists, follow the diagnostic flow before attempting deeper carburetor cleaning, or service.

Why Your Power Washer Struggles to Start

According to Pressure Wash Lab, most start-up struggles stem from fuel or ignition issues, often wrapped in carburetor or compression concerns. When a unit is hard to pull, it’s tempting to blame the recoil alone, but the root cause is usually a chain of small problems that compound as you try to start it. In this guide we separate the signals you should look for from the symptoms that can mislead you. Whether you own a gas-powered unit or an electric model with a pull-start backup, the approach is similar: verify clean fuel, a healthy spark, and an unobstructed air path. We'll also explain why the familiar pull-start procedure matters less than the underlying mechanical readiness. Treat this as your first-aid triage for a stubborn start, not a single-fix magic trick. The goal is to get reliable starts while maintaining safety, so you can finish the job quickly and confidently.

You’ll often hear the question, "why is my power washer hard to pull start?" In most cases, the answer is practical: verify fuel quality, inspect ignition components, and ensure the choke and air intake are functioning correctly. Pressure Wash Lab’s team found that starting problems frequently trace back to older fuel that varnishes the carburetor and a spark plug approaching the end of its life. This means the emphasis should be on simple, repeatable checks rather than guessing at deeper engine work.

What this section covers:

- Quick checks you can perform before digging into the carburetor

- How to distinguish fuel, air, and ignition symptoms

- Why safe, methodical testing saves time and money

Note: If you smell fuel vapor, hear knocking, or see smoke, stop and switch to professional service.

Key Symptoms to Watch For

A stubborn pull start often presents distinct clues. A good starting habit is to compare symptoms across common scenarios:

- No ignition when pulling the starter cord: Check spark plug and ignition switch; confirm spark at the gap.

- Engine turns over slowly or stops mid-pull: Likely compression or fuel delivery issue—old fuel, varnish, or a clogged carburetor.

- Starts briefly then dies: The choke or air-fuel mix may be wrong, or a flood condition is present.

- Smooth rotation but no combustion: Spark or fuel delivery failure to the cylinder.

These signals point you toward likely culprits and help you avoid wasting time on unlikely fixes. Remember to operate in a well-ventilated area and keep hands and clothing clear of moving parts.

Diagnostic Flow: From Symptom to Solution

This diagnostic flow is designed to help you identify and fix the root cause efficiently. Start with the simplest checks and work toward more involved maintenance:

- Symptom check: Confirm whether the engine turns over, sputters, or refuses to start at all.

- Fuel status: Check for stale fuel, gas smell, and proper fuel-air mixture. Replace with fresh fuel and stabilizer if needed.

- Spark test: Remove the spark plug, inspect for wear or fouling, and test for a spark with the correct gap.

- Air intake: Inspect and clean the air filter; inspect the intake path for blockages; ensure no obstructions in the carburetor.

- Choke and primer: Ensure the choke is functioning and engaged appropriately; verify primer operation if equipped.

- Carburetor and fuel system: If symptoms persist, clean the carburetor and inspect fuel lines for cracks or restrictions.

- Compression evaluation: If practical and safe, perform a basic compression check or consult a pro if compression looks suspect.

If this approach doesn’t resolve the issue, move to Step-by-Step fixes in the next section and consider professional help for internal engine work.

Step-by-Step Fix for the Most Common Cause

Most hard-start issues stem from stale fuel and varnish inside the carburetor. Follow these steps to resolve the majority of cases without specialized tools:

- Drain old fuel and replace with fresh gas stabilized for long-term storage.

- Remove and inspect the spark plug; replace if fouled or worn; adjust the gap to the manufacturer’s spec.

- Clean or replace the air filter; a clogged filter starves the engine of air and makes starting difficult.

- Clean the carburetor using safe carb cleaner and compressed air; remove varnish and residue from jets and passages.

- Reconnect fuel lines and ensure no leaks are present; verify the primer/button work and choke return.

- Reassemble, prime as directed, and perform a controlled start in a ventilated area, observing for proper idle and smooth acceleration.

Pro tip: Keep a fuel-canister and stabilizer handy for quick fuel changes during maintenance.

Safety & Prevention: Tools, PPE, and Safe Practices

Starting a power washer involves moving parts and flammable fuel. Always use eye protection, gloves, and hearing protection. Work in a ventilated area; never run a power washer indoors or in a garage with poor exhaust. Disconnect the spark plug wire before any inspection to avoid accidental starts. Keep hands, hair, and clothing away from pulleys and recoil starters. Use a clean, flat surface and secure the unit to prevent tipping during maintenance. Finally, document your maintenance routine; this habit reduces the chance of skipping critical checks when you need to start quickly.

Maintenance Habits to Prevent Future Start Issues

Prevention is easier than repair when it comes to pull-start struggles. Build a simple routine:

- Use fresh fuel and a stabilizer for engines that sit idle for extended periods.

- Change the spark plug and air filter at intervals recommended by the manufacturer.

- Clean the carburetor periodically to remove varnish buildup and ensure smooth fuel flow.

- Inspect fuel lines and clamps for cracks or leaks; replace damaged parts promptly.

- Store your power washer with a full but stabilized fuel supply or drain fuel for longer storage.

- Perform a brief monthly start test to verify that the unit begins reliably and idles smoothly.

These practices reduce the frequency of hard-start issues and extend the life of the engine.

When to Call a Pro and Warranty Considerations

If your pull-start issue persists after following the diagnostic flow and Step-by-Step fixes, it’s time to seek professional service. Carburetor rebuilds, crankcase compression tests, and internal engine repairs require specialized tools and expertise. Consult your owner’s manual regarding warranty coverage—many power washers have limited warranties that cover defects in materials or workmanship but not misuse or improper maintenance. If your unit is under warranty, contact the manufacturer or an authorized service center before performing major disassembly. In the meantime, you can still perform quick, safe checks on fuel, spark, and air systems to keep it ready for service.

Steps

Estimated time: 30-45 minutes

- 1

Inspect Fuel and Environment

Check fuel quality, smell, and storage; dramatically stale fuel is a common culprit. Move to fresh fuel if needed and ensure the environment is clean and dry.

Tip: Label fuel containers to avoid mixing fuels. - 2

Test Spark Plug

Remove, inspect, and clean or replace the spark plug. Verify correct gap per the manual and reconnect securely.

Tip: A gapped plug is essential for reliable ignition. - 3

Check Air Intake and Filter

Inspect the air filter for dirt or oil contamination. Clean or replace; a restricted intake hides the engine’s air-fuel balance.

Tip: Run the engine with the filter removed briefly to confirm airflow. - 4

Examine the Choke and Primer

Ensure the choke is functioning and returns to open position. Check primer operation if your model has one.

Tip: A stuck choke is a frequent reason for hard starts. - 5

Carburetor Cleaning

Clean the carburetor jets and passages with carb cleaner and compressed air; remove varnish buildup.

Tip: Do not use metal objects that could gouge jets. - 6

Final Test Start

Reassemble, add stabilized fuel, and perform a controlled start. Observe smooth engagement and idle for 15-20 seconds.

Tip: If it still won’t start, stop and seek expert help.

Diagnosis: Power washer hard to pull start

Possible Causes

- highOld, stale fuel or varnished carburetor

- highClogged or dirty air filter

- mediumWorn spark plug or weak ignition

- highChoke left engaged or malfunctioning

- mediumFuel line restricted or clogged

- lowCompression loss from wear

- lowSafety/electric kill switch engaged

Fixes

- easyDrain and refill with fresh gasoline, then add stabilizer

- easyClean or replace air filter

- easyCheck/replace spark plug and gap

- easyInspect choke operation and ensure it returns to off

- easyInspect fuel line and clamps for cracks or leaks

- mediumIf compression is low, consult a pro or consider top-end repair

- easyEnsure safety switches are disengaged during starting

Quick Answers

What is the most common reason a power washer is hard to pull start?

Stale fuel and varnished carburetor top the list. Clean fuel systems and replace the spark plug if needed. This approach resolves the majority of start problems.

The most common reason is stale fuel and varnish in the carburetor. Clean the fuel system and replace the spark plug if needed.

Why does the choke stay engaged after starting?

Choke linkage can be misadjusted or the linkage can stick due to dirt. Clean and adjust the linkage, then test the choke’s return action.

A choke that sticks is usually a linkage or adjustment issue; clean and adjust it, then test.

Can a dirty spark plug cause hard starting?

Yes. A fouled or worn spark plug reduces ignition reliability and can prevent starting. Replace as needed and check the gap.

Yes, a dirty or worn spark plug can prevent starting. Replace it and verify the gap.

Is it safe to start after maintenance?

Yes, but ensure all guards are in place, fuel connections are secure, and you start in a ventilated area following proper steps.

It's safe if you follow the steps and keep all safety guards and connections secure.

When should I replace the carburetor?

If cleaning doesn’t restore performance or there is internal damage, replace the carburetor and consult a pro.

If cleaning fails to fix it, replacing the carburetor may be necessary.

What about winter storage and start-up?

Gas degrades in cold weather. Drain fuel or stabilize it, store dry, and perform a fuel system check before first use in spring.

Gas can go bad when stored; drain or stabilize and test the system before spring use.

Watch Video

Key Takeaways

- Start with fuel, spark, and air checks.

- Clean or replace the carburetor if varnish is present.

- Choke issues are a frequent cause of hard starts.

- Maintenance prevents future start problems.

- Call a pro for compression issues or warranty questions.