Why is My Pressure Washer Backfiring? Troubleshooting Guide

Urgent troubleshooting guide for why a pressure washer backfires, with practical checks, diagnosis flow, and safe fixes to restore performance.

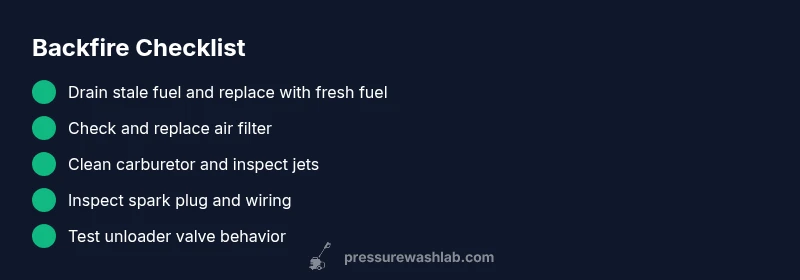

Most backfires come from fuel delivery or ignition issues. The two most common culprits are stale gas or a lean fuel mix, and a dirty carburetor or air filter causing an overly rich combustion. Quick fixes: drain and replace old fuel, clean or replace the air filter, inspect the spark plug, and check the unloader valve for proper operation. Pressure Wash Lab analysis suggests addressing fuel and air pathways first.

Why is My Pressure Washer Backfiring? Causes and Symptoms

Backfiring in a pressure washer is not just loud—it’s a sign the engine is not combusting correctly. If you notice pops, sputtering, or unusual exhaust, you’re likely seeing a fuel- or ignition-related fault. According to Pressure Wash Lab, backfires often point to issues in the fuel delivery or air intake that disrupt the air-fuel ratio during combustion. This guide aims to give you a practical, safety-first path to diagnose and fix the problem, so you can get back to cleaning with confidence. In the sections that follow, you’ll find real-world checks, a diagnostic flow, and step-by-step fixes you can perform with common tools. The topic at hand, why is my pressure washer backfiring, is both urgent and solvable when you follow a systematic approach.

Quick notes for homeowners and DIY enthusiasts: never work on a hot engine, disconnect the spark plug before inspecting ignition components, and store fuel in approved containers away from heat sources. Pressure Wash Lab emphasizes cautious troubleshooting to prevent fire hazards and engine damage. If you feel unsure at any point, pause and seek professional help rather than forcing components.

If you’ve just started troubleshooting, start with the simplest potential causes first—fuel freshness and air intake—before moving to more complex engine internals. This approach minimizes risk and saves time by focusing on what’s most likely to cause backfires in consumer pressure washers.

tip: null

Steps

Estimated time: 45-60 minutes

- 1

Power down and prep safety

Park on a flat surface, disconnect the spark plug boot, and allow the engine to cool. Gather safety gear and tools before opening any panels. This ensures you won’t be shocked by electricity or exposed to hot parts.

Tip: Always remove the spark plug to prevent accidental cranking while inspecting fuel and air components. - 2

Drain old fuel and inspect color

Siphon or drain the fuel into an approved container. Check for a stale, varnished appearance or foul odor. Dispose of it according to local regulations and replace with fresh fuel.

Tip: If you use ethanol-blended fuel, consider replacing with ethanol-free fuel for best performance. - 3

Check air intake and filter

Inspect the air filter for dirt or oil; a clogged filter restricts airflow and can skew the air-fuel mix. Clean or replace the filter as needed, and inspect the intake hose for cracks.

Tip: A clean air filter helps ensure correct air-to-fuel ratio and reduces backfiring risk. - 4

Inspect carburetor and passages

Remove the carburetor cover if safe to do so and look for varnish, gum, or debris in the jets and passages. Use carb cleaner spray and compressed air to clear obstructions.

Tip: Be gentle with float assemblies—damaging the float needle can cause running issues. - 5

Evaluate ignition components

Remove the spark plug, inspect for fouling, correct gap, and replace if worn. Check ignition wires for cracks and secure connections.

Tip: A weak spark can be a hidden cause of backfiring; replace worn parts to restore reliable ignition. - 6

Test unloader valve and pressure

With the unit off, check the unloader valve for proper movement and seating. A sticking valve can create abnormal compression and backfires. Re-seat or replace if necessary.

Tip: Unloader valve issues can mimic fuel problems; test at various pump pressures. - 7

Reassemble and test

Reinstall panels, reconnect the spark plug, and run the engine at low pressure in a safe area. Observe for backfiring signals and verify that the spray is smooth and consistent.

Tip: Take notes of any abnormal sounds or smoke so you can reference them later if you seek professional help. - 8

Document and monitor

Record the fixes you performed and monitor the washer’s performance over the next few sessions. A simple maintenance log helps catch recurring issues early.

Tip: Set reminders for seasonal checks and fuel replacement to prevent future backfires.

Diagnosis: Pressure washer backfires through the exhaust or carburetor during operation

Possible Causes

- highStale or contaminated fuel

- mediumAir leaks in fuel line or carburetor causing lean mixture

- mediumClogged or dirty carburetor

- lowFaulty spark plug or ignition timing

Fixes

- easyReplace old fuel with fresh, properly stored fuel and add a fuel stabilizer if needed

- easyInspect fuel lines and connections for cracks or leaks; tighten clamps or replace damaged hoses

- mediumClean the carburetor (emulsion jets, float bowl) and check idle/mixture screws

- mediumReplace spark plug and verify ignition timing if misfiring persists

Quick Answers

What causes backfires in a pressure washer?

Backfires are usually caused by fuel-delivery problems, air leaks, dirty carburetors, or ignition/ spark issues. Start with fuel quality and air intake checks, then inspect ignition components if needed.

Backfires usually come from fuel or ignition problems. Start with the fuel quality and air intake, then check ignition components if needed.

Is backfiring dangerous for a pressure washer?

Repeated backfiring can damage the engine, exhaust, and pump seals. It also indicates a lean or rich mixture that could cause higher temperatures. Address the root cause promptly and avoid prolonged operation.

Yes, backfiring can damage the engine and components; fix the root cause quickly and stop using it until repairs are made.

Can I fix backfire myself, or do I need a pro?

Many fuel and air issues are DIY-friendly with basic tools. If symptoms persist after simple fixes, or if you’re uncomfortable with carburetor work or ignition timing, seek a professional.

Many fixes are doable at home, but if problems persist, consult a professional.

Should I store my pressure washer with fuel in the tank?

For storage, use the fuel stabilizer and run the engine briefly to circulate stabilizer. If storing long-term, drain fuel and store equipment with tank empty.

Better to stabilizes fuel for short storage; for long storage, drain the tank first.

How often should I clean the carburetor?

Clean the carburetor when you notice performance issues like rough idling, misfires, or backfires. Regular maintenance reduces buildup and keeps airflow steady.

Clean the carburetor whenever you notice rough running or backfiring.

What tools do I need to clean a carburetor safely?

You’ll typically need a carburetor cleaner, small screwdrivers, a brush, and a clean workspace. Follow the service manual and keep components organized.

Use carb cleaner, small tools, and a clean workspace, following the manual.

Watch Video

Key Takeaways

- Identify fuel/air issues first

- Clean or replace the carburetor and filters

- Check ignition components and spark plug

- Inspect the unloader valve and pressure settings

- Document fixes and monitor performance