Why Your Pressure Washer Won’t Turn On and How to Fix It

Urgent, step-by-step troubleshooting to diagnose why a pressure washer won't turn on. From power checks to safety interlocks, learn fast fixes and prevention tips to get back to work quickly.

Most often, a pressure washer won’t turn on due to a simple power or safety interlock issue. Start with the basics: verify the outlet is live, inspect the extension cord for damage, and reset any GFCI. Then check the unit’s power switch and trigger interlock. If there’s still no response, inspect fuses, wiring, and the safety switch; professional service may be needed.

Understanding the problem: why is pressure washer not turning on

If you’ve just powered up your pressure washer and it stays silent, you’re not alone. Many homeowners search for 'why is pressure washer not turning on' in frustration. This situation is urgent because it halts your project and can hide simple safety issues in plain sight. According to Pressure Wash Lab, the majority of startup failures come from electrical or safety interlock problems rather than a seized motor. By starting with a quick check of the power source and safety features, you can often diagnose the root cause in minutes. In corded electric models, a non-start can mean anything from a tripped GFCI to a loose connection at the switch. In gas-powered units, the issue might be fuel, spark, or a shutdown switch. Across categories, the common theme is ease of access to checks you can do without disassembling your machine. This article will guide you through a safe, methodical approach that matches the urgency of needing a working washer for driveway or siding jobs.

The keyword here is practical troubleshooting, not guesswork. By keeping a calm, stepwise plan, you avoid accidental shocks or further damage. You’ll learn to differentiate between safety interlocks and real power faults, and you’ll gain confidence in performing basic diagnostics that save time and money. Pressure Wash Lab’s approach blends common-sense checks with manufacturer guidance to deliver results quickly.

Quick checks you can do before opening the unit

Before you unscrew a single panel, run through these immediate checks. First, ensure the outlet is live: plug a lamp or charger into the same circuit to confirm power. If you have a GFCI outlet or an outdoor-rated circuit, reset the breaker and push the reset button on the GFCI. Next, inspect the extension cord for cuts, nicks, or loose connectors; a damaged cord can masquerade as a dead inlet. If the cord seems okay, replace it with a known-good one of equal or greater gauge. Then verify the power switch on the machine is in the 'on' position and that the trigger gun is not locked or stuck in a safety-latch position. A partially engaged trigger can prevent the unit from starting even if the switch feels fine. Finally, examine the fuse or internal safety cutoff if your model has one; a blown fuse will stop all startup actions. If you find any of these issues, address them and test again.

Electrical power verification: outlet, cord, and switch

Power delivery is the most frequent cause of a non-start situation. Start with the simplest: test the outlet with a small appliance, like a lamp, to confirm voltage is present. If the outlet checks out, move to the extension cord. A cord rated too low for the washer’s amperage can overheat and fail under load. Use a heavy-duty, outdoor-rated cord and ensure it is fully plugged into both ends. Next, test the washer’s power switch: with the unit unplugged, unplug and reseat the switch connections; if you notice corrosion or obvious damage, replace the switch. Check for loose ground wires or a damaged plug; even a securely connected cord can fail if the plug pins are burnt. If your model has a resettable breaker inside, try resetting it. Note that some models require a specific sequence: switch on, then pull the trigger slightly to bypass a safety interlock. If none of these steps resolve the issue, move to interlock and safety components.

Safety interlocks and trigger gun testing

A surprisingly small component can keep a pressure washer from turning on. The trigger gun has a safety interlock that requires the trigger to be squeezed to complete the electrical circuit. If the gun is worn or the coupler is clogged with debris, the interlock may never register a start command. Inspect the trigger mechanism for corrosion, bent parts, or grime buildup. Disconnect power before you inspect. If you can safely press the trigger and hold it, see if the unit latches on; if it doesn’t, the interlock or micro switch in the gun or wand may be failing. Some units also include a safety switch near the handle that alarms if the wand is misaligned. Also check that the spray wand is fully latched in its cradle; a disconnected wand can prevent starting in some designs. If you identify wear, replace the interlock or the whole trigger assembly as recommended by the manufacturer, and retest.

Fuel, spark, and engine controls (gas-powered models)

For gas-powered pressure washers, the issue is rarely electrical but fuel and ignition related. Ensure the fuel valve is open and the tank isn’t empty; stale fuel can cramp performance. Check the spark plug for gaps or fouling and verify that the spark plug wire is firmly connected. If the engine has a low-oil sensor, confirm the oil level is correct and that the sensor isn’t triggering a shutdown. Some models have an anti-restart safety feature that requires a cooldown period after a fault; wait a few minutes and try again. Remember that some engines require a choke to start in cold conditions; follow the starting procedure exactly as the manual indicates. Gas engines also have kill switches near the engine housing; ensure these switches aren’t inadvertently engaged. If you discover fuel contamination or a faulty spark plug, replace components as needed and attempt a restart. If the engine still won’t turn on, consult a technician, since more complex electrical or mechanical issues may be involved.

Water supply, priming, and pump readiness (safety-first startup)

Sometimes a washer seems non-responsive because water cannot reach the pump. Ensure the water supply is on and the inlet screen is free of debris. If the pump is dry or air-locked, you might hear coughing noises or see no spray even when the trigger is held. Check the inlet hose for kinks and confirm the water pressure is adequate for safe operation. Some machines require priming; if priming is needed, follow the manual’s steps to prime the pump before the first start. If the pump is seized due to long storage, you may need a gentle prime and longer cranking to overcome a dry seal. While these steps don’t directly turn the motor on, failing to deliver water can mask an electrical startup problem by triggering safety features. Inspect the unloader valve for obstruction as well, since a stuck valve can keep the pump from priming and may prevent full pressurization, making it seem like the machine won’t turn on.

Common component failures and what to do

If the unit still does not start after the above checks, you may be facing a failed component. The safe bet is to inspect the internal fuse or circuit board for signs of damage or burn marks. If your model has a thermal cutoff switch, verify it has not tripped. Worn relays or contactors inside the unit can prevent start-up, and replacing them is often best left to a technician. For electric models, a burnt smell or melted insulation near the power input is a red flag. If the unit is old or subjected to frequent outdoor use, the switchgear may require replacement. When replacing parts, always consult the manufacturer’s guide for compatible parts and proper torque specs. Finally, remember that moisture and water exposure can corrode critical connections; dry all accessible components before retesting. If you are unsure about electrical components or lack the right tools, stop and seek professional assistance to avoid shock hazards or further damage.

Prevention and maintenance to avoid startup issues

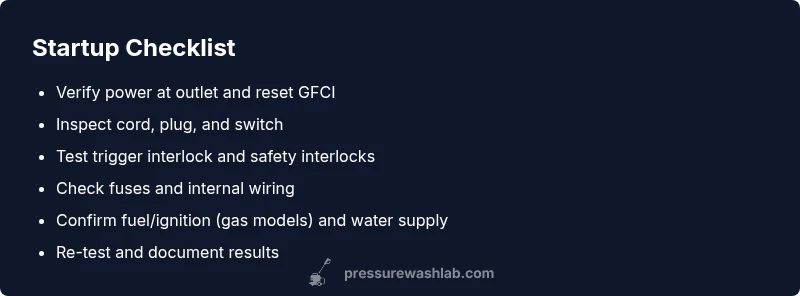

The best defense against the problem described by the keyword 'why is pressure washer not turning on' is proactive maintenance. Regularly inspect electrical cords and outlets, store equipment in a dry place, and replace frayed cords promptly. Keep the trigger gun and wand clean, and routinely test safety interlocks to ensure they function smoothly. Schedule annual checkups or professional tune-ups, especially for gas-powered models that rely on the ignition system. Use manufacturer-recommended oils, fuels, and cleaners and keep a spare fuse or safety switch on hand if your model allows it. Clean the inlet screen after every heavy-use session to prevent debris from silently causing a no-start condition. Finally, document a simple startup checklist for future sessions, including steps like checking water supply, verifying power, and testing the trigger. This habit reduces downtime and ensures you can quickly diagnose issues if they arise again.

Steps

Estimated time: 30-60 minutes

- 1

Verify power and switch

Confirm the unit is plugged in and the power switch is in the ON position. If the outlet doesn’t show voltage, stop and address the power source first. Re-seat any plug-in connections and inspect for obvious damage.

Tip: Unplug before inspecting connectors to avoid shock. - 2

Test outlet and extension cord

Plug a lamp into the same outlet to confirm power. If using an extension cord, ensure it’s heavy-duty and in good condition. Replace damaged cords with a same-or-better gauge cord.

Tip: Use a new cord of adequate gauge; don’t daisy-chain multiple cords. - 3

Inspect trigger interlock

With power off, examine the trigger mechanism for grime or damage. Squeeze the trigger while observing the safety interlock to ensure it completes the circuit. If stuck, you may need a new trigger assembly.

Tip: Test by gently cycling the trigger to twice to verify smooth operation. - 4

Check safety interlocks and fuses

Inspect any internal fuses or breakers. If a fuse appears blown, replace per the manufacturer’s part numbers. Ensure the safety switch and any interlock microswitch are functioning.

Tip: Never bypass safety interlocks; they are there to prevent injury. - 5

Gas model checks (if applicable)

For gas-powered units, verify fuel, spark plug condition, and ignition components. Ensure the choke is used correctly in cold starts and that there is sufficient fuel with proper oil mix if required.

Tip: Use fresh fuel and avoid ethanol-rich blends if not recommended by the manual. - 6

Final test and escalation

Reconnect power and perform a test run. If the unit still won’t start, document symptoms and consult a professional technician. Persistent issues may indicate a control board or motor failure.

Tip: Take photos of wiring before any replacement for reference.

Diagnosis: Pressure washer won't turn on or respond when power is pressed.

Possible Causes

- highNo power at outlet (tripped breaker, dead circuit)

- mediumFaulty power switch or damaged wiring

- highGFCI outlet or safety switch tripped

- highInterlock on trigger gun not engaged

- lowBlown fuse in the unit's control circuit

Fixes

- easyTest outlet with a known-good device; reset breakers and GFCI; try a different outlet

- easyInspect the power switch and visible wiring; reseat connections; replace damaged cords

- easyReset or replace the GFCI/safety interlock; check the trigger gun for full compression

- mediumCheck fuses or internal disconnects; if unresolved, seek professional service

Quick Answers

Why won't my electric pressure washer start after storage?

Storage can leave moisture or corrosion on connectors. Check outlet power, reset any GFCI, inspect the cord and switch, and test the trigger interlock. If it still won’t start, inspect internal fuses or contact a pro.

Moisture or corrosion after storage can block startup. Check power, then interlocks; seek pro help if unresolved.

Can a faulty trigger gun prevent startup?

Yes. The trigger interlock must be engaged for the circuit to complete. Inspect the gun for debris, wear, or a faulty micro switch and replace if needed.

A worn trigger interlock can stop startup; inspect and replace if necessary.

Is it safe to reset the GFCI when the washer won’t start?

Resetting a GFCI is a standard safety step. If the outlet or outdoor circuit keeps tripping, there may be a larger electrical fault that requires inspection.

Reset the GFCI and test again; persistent trips mean a professional should check the circuit.

What should I do if the outlet is live but the washer still won’t start?

Inspect the power switch, wiring, and any built-in fuses. A loose connection or blown fuse inside the unit can block startup even with power at the outlet.

Outlet power isn’t enough—check switch and internal wiring as well.

Do I need professional service for a motor that won’t start?

If basic checks fail, a professional can diagnose motor, board, or relay failures safely and efficiently.

Yes—slow startups or non-starts after basic checks often need a pro.

Can weather affect starting a pressure washer?

Cold weather can make starting harder due to fuel and lubrication changes in gas models. Follow cold-start procedures from the manual.

Cold conditions can impede starts; follow cold-start steps as recommended.

Watch Video

Key Takeaways

- Start with power and safety checks.

- Test outlets, cords, and switches first.

- Interlocks and safety features are common startup culprits.

- Gas models need fuel and ignition checks.

- Routine maintenance minimizes startup downtime.