Why Is Your Pressure Washer Surging? A Practical Troubleshooting Guide

Learn how to diagnose and fix why a pressure washer surges with a practical, step-by-step approach from Pressure Wash Lab. Air, fuel, and valve issues are covered with safe, actionable tips.

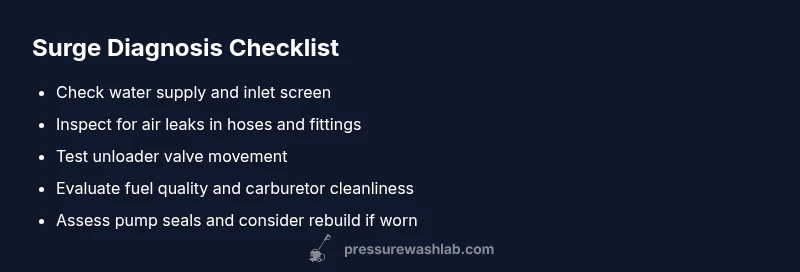

Most surging pressure washers are caused by air or fuel delivery issues, or a sticking unloader valve. Start by ensuring the water supply is steady, the fuel is clean, and the unloader valve moves freely. If the surge persists, adjust the pressure control slowly or replace worn carb components. For safety, shut off the engine before inspecting parts.

Why surging happens and how to assess it

If you’re asking why is pressure washer surging, the answer usually points to three broad categories: air entering the system, fuel delivery problems, or a malfunctioning unloader valve. Start with the simplest checks: confirm the water supply is steady, look for air in hoses, and inspect clamps for tightness. When an engine or pump loses a stable supply, the system briefly reduces pressure and then ramps back up, creating a noticeable oscillation. Pressure Wash Lab's analysis shows that homeowners frequently overlook tiny air leaks at quick-connects or a dry primer bulb, which can create the same surging behavior as a bad regulator. In most residential units, a tiny amount of air can trick the pump’s pressure relief cycle into firing, causing the surge. By focusing on airtight connections first, you can often stop the surge without expensive parts. This is why the initial steps in troubleshooting are so critical.

Quick checks you can perform without tools

If you want to diagnose quickly, start with the simplest things. Ensure the water supply is steady and the inlet screen is clean. A partial water restriction can cause the pump to starve and surge as it tries to maintain pressure. Inspect all hoses for kinks and ensure clamps are tight. Loose connections invite air, which the pump senses as a change in flow. Remove and reattach quick-connect fittings to seal air leaks. Verify nozzle tips are appropriate for the pump's PSI rating; using a too-narrow spray can create resistance that looks like surging. Finally, try priming the system by cycling the trigger with the trigger gun closed; if water bleeds back, there may be an air leak somewhere along the suction line. These checks usually take minutes and often resolve intermittent surges without disassembly.

Air leaks, priming, and water inlet: why it matters

Air in the suction line destabilizes the pump’s sense of flow, causing a surge as it tries to compensate. Leaks at fittings, gaskets, or the inlet screen can introduce air that disturbs pressure regulation. Priming issues – such as a dry primer bulb or a loose connection – mimic a failing regulator. The water inlet must stay clean and free of debris; a clogged screen reduces flow and triggers oscillations. To diagnose, run the unit with the wand off and watch for air bubbles in the inlet or primer bulb; note where leaks occur and address them first. If you find obvious leaks, reseal or replace parts before moving on to more complex tests.

Fuel system fundamentals: fuel quality, stabilization, and carburetor behavior

Surging is often a symptom of inconsistent fuel delivery. Old fuel can degrade, varnish passages, and cause erratic carburetor behavior. Use fresh gasoline and appropriate stabilizers if you store the unit for long periods. Ethanol blends can contribute to varnish buildup in small engines; consider using ethanol-free fuel if available. A dirty fuel line, clogged filter, or a partially blocked carburetor jet can create a lean or rich condition that fluctuates with engine speed, producing a surge. When inspecting the fuel system, check the fuel filter, drain and replace old fuel, and verify that the carburetor isn’t gummed up by varnish. Perform a careful idle and quick throttle adjustment to see if the surge smooths out after fuel stabilization.

Unloader valve and pressure regulation explained

The unloader valve directs or redirects water flow and regulates pressure in most pressure washers. If it sticks, leaks, or is misadjusted, the machine can surge as it tries to reach set pressure. Check that the valve moves freely when you manually cycle the lever, and verify the springs and seals for wear. If the valve is corroded or damaged, cleaning may help, but replacement is often necessary for reliable operation. After adjustments, re-test at multiple nozzle tips to confirm stable pressure across the range. Remember that improper tuning can cause safety hazards, so proceed conservatively and with the engine off when inspecting internal components.

Pumps, seals, and internal wear: when to service

Worn pump seals, piston rings, or check valves can introduce leakage and oscillation that feels like surging. If you’ve ruled out air and fuel issues, inspect the pump head for oil leaks, scoring, or excessive play in the pistons. A rebuild kit can restore performance, but it’s often best handled by a qualified technician if you’re not comfortable disassembling components. In some cases, replacing the pump or motor assembly is more cost-effective than an extensive rebuild. When in doubt, consider the unit’s age and usage history to decide between repair and replacement.

Safety, maintenance, and prevention: end-to-end practice

Prevention is the best cure for surging. Develop a routine to replace fuel and air filters, inspect hoses for cracks, and clean the inlet screen regularly. Store gasoline in approved containers and label any stabilizers used. Always depressurize and turn off the engine before servicing any internal parts. Use the correct nozzle and avoid forcing the system beyond its rated PSI. Finally, document the service steps you take and monitor performance after each maintenance cycle to catch future surges early.

Steps

Estimated time: 60-90 minutes

- 1

Ensure safety and power down

Shut off the engine, disconnect the spark plug wire (or remove battery on electric models), and release stored pressure by pulling the trigger with the gun open. This prevents accidental discharge during inspection.

Tip: Always work with the unit cool and away from flammable materials. - 2

Check water supply and inlet

Verify the water source is consistent and the inlet screen is clean. Remove kinks from hoses and ensure no debris is restricting flow. Reconnect all fittings securely to prevent air intake.

Tip: Prime the line by squeezing hoses to expel air before reconnecting the wand. - 3

Inspect for air leaks

With the unit running at idle (if safe), listen for hissing sounds and look for damp spots around hose connections. Tighten clamps and replace damaged hoses or gaskets as needed.

Tip: A simple soapy water spray can quickly reveal small leaks. - 4

Assess the unloader valve

Cycle the unloader lever while observing it move freely. If you hear a sticking or grinding noise, or the lever feels stiff, clean the valve or replace worn parts.

Tip: Avoid forcing the valve; improper handling can cause further damage. - 5

Evaluate the fuel system

Drain old gas, fill with fresh fuel, and check the fuel filter. If the engine still surges, inspect carburetor jets for varnish and clean if necessary.

Tip: Stabilizer helps if you don’t use the machine often. - 6

Test with different nozzles

Switch between nozzle tips to see if surging changes with load. A nozzle delivering too high resistance can mimic a surge even when components are fine.

Tip: Keep to the manufacturer-recommended nozzle range. - 7

Decide on service vs. replacement

If wear is evident in seals, pistons, or the pump head, weigh the cost of rebuild against a replacement unit. For high-hour gear, a proactive replacement may be best.

Tip: Record your test results for future reference.

Diagnosis: Pressure washer surges or fluctuates while running

Possible Causes

- highAir leaks or improper priming

- highUnloader valve sticking or misadjusted

- mediumFuel quality or old fuel

- mediumWater supply restriction or suction issues

- lowWorn pump seals or piston rings

Fixes

- easyInspect for visible air leaks in hoses, connections, and nozzle; reseat clamps and replace damaged sections

- easyCheck unloader valve movement; clean or replace if sticking; verify springs and seals

- easyReplace or clean fuel; use fresh fuel with ethanol-appropriate blend; add stabilizer

- easyEnsure water supply is steady; check inlet screen, hose kinks; remove air by priming lines

- mediumIf pump seals or pistons show wear, schedule professional rebuild or replacement

Quick Answers

What causes a pressure washer to surge?

Surging is typically caused by air leaks, fuel delivery problems, or a faulty unloader valve. Each category affects how the pump maintains pressure and can be diagnosed with simple checks.

Surging is usually due to air leaks, fuel problems, or a faulty unloader valve. Check these areas step by step.

Can a dirty carburetor cause surging?

Yes. A varnished or clogged carburetor jet can cause inconsistent mixture and engine speed, leading to surging. Clean or rebuild as needed.

A dirty carburetor can cause uneven engine speed and surging. Clean or rebuild to restore stability.

Is surging dangerous for my pressure washer?

Surging indicates abnormal operation and can stress components. Stop the device if the surge worsens and inspect safety-critical parts before continuing.

Surging isn’t just annoying—it can stress parts. Stop and inspect if it gets worse.

Do I need a professional to fix surging?

Not always. Start with air, water, and fuel checks. If the problem persists or involves the pump internals, professional service may be required.

You can often diagnose and fix simple causes yourself, but pump work may need a pro.

Will changing nozzle tips affect surging?

Yes. A mismatch between nozzle size and pump capability can alter load and mimic surging. Use the recommended nozzle range.

Wrong nozzle tips can make surging seem worse. Stick to the recommended range.

How can I prevent surging in the future?

Regular maintenance, fresh fuel, clean filters, and proper storage help prevent surges. Inspect hoses and seals periodically.

Regular maintenance and clean fuel prevent surges from happening.

Watch Video

Key Takeaways

- Identify whether air, fuel, or valve issues trigger surging

- Start with quick, safe checks before disassembly

- Adjust unloader valve conservatively and test with multiple nozzles

- Use fresh fuel and proper additives to stabilize performance

- Know when to call a professional for pump repair