Why My Power Washer Won t Start: Troubleshooting Guide

Urgent troubleshooting guide to diagnose why my power washer won t start and fix common startup issues safely for homeowners and pros. Step-by-step checks, safety tips, and when to call a pro.

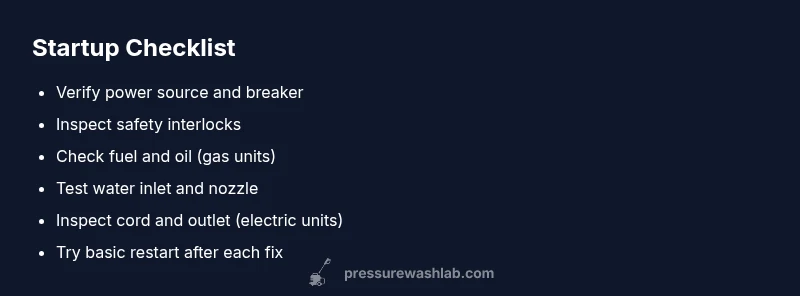

Most power washers fail to start due to simple, fixable issues. First, confirm the unit is powered: plug in, an outlet is live, and a circuit breaker isn’t tripped. For gas models, check fuel level, oil, and fuel line; for electric models, inspect the safety switch, trigger gun, and extension cord. If it still won’t start, proceed with deeper checks in the body.

Common Startup Causes for a Power Washer Won t Start

Startup failures are most often rooted in power and safety basics rather than the engine itself. If you re asking why my power washer won t start, the answer is usually a simple power or safety issue. According to Pressure Wash Lab, a surprising number of no-start conditions come from a dead outlet, a tripped breaker, or a safety interlock that hasn’t been released. Gas models add fuel and carburetor complications if fuel sits too long, while electric units punish lazy cords and bad extensions with a dead outlet. In this section we cover the top culprits and how to spot them quickly before you grab tools. Expect explanations that apply to most DIY setups and model families, and note the small differences between electric and gas units.

- Read the label on the power switch and ensure the switch isn’t stuck in the off position.

- Check the GFCI outlet; test with a known-good device to confirm power flow.

- Inspect the extension cord for cuts, damaged insulation, or inadequate gauge that could starve the motor.

- If your unit is gas-powered, verify the fuel has not degraded and the oil level is correct.

- Look for obvious safety interlocks on the trigger gun or wand that may prevent starting unless fully engaged.

Safety and Preparation: What to Check Before You Start

Safety first: never bypass safety features or run a machine with unknown electrical issues. Before you do anything, unplug the unit and wear eye protection and gloves. Confirm you have a clear, dry work area and that the water source is on and delivering adequate flow. If your unit has a spark plug, remove and inspect it for fouling or wear. For gas engines, check oil level and air filter. For gas-powered models, ensure the choke is set correctly and there is no water in the float bowl. Having the manual handy helps because models differ in the exact procedure.

Basic Checks You Can Do Quickly (No Tools Needed)

The quickest way to get to a starting point is to run through baseline checks that don’t require tools. Verify the outlet and breaker first, then test a different extension cord and plug. Inspect the trigger gun and high-pressure wand for sticking or damage. For electric models, ensure the cart or frame isn’t grounding against the surface. For gas models, confirm there’s fresh fuel, the choke is in the correct position, and the primer bulb functions. This quick triage often resolves 60-70% of no-start complaints.

Gas-Powered vs Electric: Where Startup Issues Usually Lie

Gas-powered units rely on the fuel system, carburetor, and ignition. Problems here include stale fuel, varnish buildup in the carburetor, a fouled spark plug, or a clogged fuel filter. Electric units depend on a live power source, proper cord gauge, and intact switches. If a GFCI or safety switch prevents current from reaching the motor, the engine won t turn over no matter how you pull the trigger. Distinguishing the two helps you target the right subsystem.

Fuel and Carburetor Deep Dive (Gas Units)

When a gas engine won t start, the fuel system is the most common bottleneck. Drain and replace stale fuel, then drain the carb and spray clean fuel into the line to cycle fresh fuel through. Clean the fuel filter if your unit has one and consider a carburetor kit if varnish is present. Check the spark plug for wear and replace if dark, fouled, or damaged. Don t forget to check oil level and air filter while you re in there.

Electrical Troubleshooting: Outlets, Cords, and Safety Switches

For electric washers, the choke is not a factor, but the outlet and cord are. Use a known-good outlet to test power; measure voltage if you have a multimeter. Inspect the extension cord for cuts, kinks, or damaged insulation. Replace a bad cord with a properly rated one. Check the safety switch on the trigger gun; a stuck switch or worn trigger can keep the motor from turning on, even when the switch is in the on position.

When to Call a Pro and Preventive Maintenance

If you have performed the basic checks and still can t start the unit, it s time to seek professional service. A tech can diagnose internal issues with the pump, carburetor, or electrical circuitry that require specialized tools. To prevent future no-starts, commit to a simple preventive routine: store fuel correctly, run the unit dry between seasons, replace worn hoses and nozzles, and perform regular oil and filter changes on gas-powered models.

Quick Maintenance Checklist to Prevent Startup Problems

In this preventive section we outline a lightweight routine that reduces the chance of a future no-start. Keep fuel fresh, test safety features monthly, inspect cords and outlets, and replace worn parts before they fail. A consistent maintenance habit saves time and money and keeps your workflow uninterrupted.

Steps

Estimated time: 30-60 minutes

- 1

Power up and safety check

Begin by inspecting the basics: ensure the unit is plugged in (electric) or has fresh fuel and oil (gas). Confirm the circuit breaker is on and there is no tripped GFCI. Put on safety glasses and gloves to protect eyes and hands before you touch moving parts.

Tip: Never bypass a safety switch; it protects you and the machine. - 2

Test the power source and wiring

For electric models, test the outlet with a known-good device or use a voltmeter to verify voltage. Check the extension cord for cuts or damage; replace with a properly rated cord if in doubt.

Tip: Use a voltage tester to confirm power before assuming the motor is bad. - 3

Inspect safety interlocks

Check the trigger gun and wand safety interlock. Ensure the trigger is not stuck and the wand moves freely. A misbehaving interlock will prevent the motor from starting even when other basics are sound.

Tip: Physically move the trigger several times to confirm smooth action. - 4

Gas fuel system check

If you have a gas-powered unit, confirm the fuel is fresh and in the correct mix. Inspect the fuel line and primer bulb for cracks or leaks. If fuel has degraded, drain and replace with fresh fuel and, if needed, fuel stabilizer.

Tip: Never use old fuel; it causes varnish buildup in the carb. - 5

Carburetor and spark plug

For carbureted gas units, remove the air filter housing and inspect the carb and spark plug. Clean or replace a fouled plug, and consider a carburetor kit if varnish is present. Reassemble carefully and test starting again.

Tip: Always replace the spark plug with the correct heat range. - 6

Water supply and inlet checks

Ensure the water supply is open and delivering adequate flow. Check the inlet screen for clogs and clear any debris. A restricted water supply can masquerade as a no-start condition by triggering safety shuts.

Tip: Run water through the hose to purge air from the line. - 7

Fuel-oil balance and air filter

On gas engines, verify proper oil level and check the air filter for excessive dirt. A clogged filter reduces air flow and may prevent starting. Clean or replace the filter if needed.

Tip: Service the air filter as part of routine startup checks. - 8

Decision point and maintenance plan

If the unit still won t start after these steps, document symptoms and call a technician for professional diagnosis. After successful startup, set a maintenance schedule to prevent future no-starts.

Tip: Keep records: fuel type, oil level, last service date.

Diagnosis: Power washer won't start

Possible Causes

- highPower supply issue (outlet, GFCI, or switch off)

- highSafety interlock engaged (trigger gun or wand)

- mediumGas unit with stale fuel or carburetor issues

- mediumElectrical outlet/cord fault in electric models

- lowLow oil level in gas engine

- lowWater inlet or filtration blockage

Fixes

- easyTest outlet with a known-working device and reset any GFCI; restore power

- easyInspect trigger gun safety interlock and replace if stuck or worn

- mediumGas unit: drain and replace stale fuel, clean or replace carb components

- easyElectric model: test the extension cord and outlet with a multimeter; replace damaged cord

- easyCheck oil level and top up to recommended level; replace oil if contaminated

- easyInspect water inlet and filter, ensure water supply is open and unobstructed

Quick Answers

Why won t my power washer start after sitting idle?

Stale fuel, a fouled spark plug, and clogged fuel lines are common culprits for gas units. For electric units, a tripped circuit or faulty cord can prevent startup. Start with fresh fuel, inspect safety interlocks, and check power supply.

Stale fuel or a bad electrical connection are the usual culprits. Start with fresh fuel and a quick safety check.

My electric power washer won’t start. What should I check first?

Check the outlet and circuit breaker, test with a known-good device, inspect the extension cord, and verify the safety switch on the trigger gun is functioning. Replace any damaged cords.

The first checks are outlet, breaker, and the safety switch.

Can old fuel cause a gas power washer not to start?

Yes. Old or degraded fuel can varnish the carburetor and prevent starting. Drain and replace with fresh fuel and add a small amount of fuel stabilizer if long storage is expected.

Old fuel can clog the carburetor and stop starting. Replace it with fresh fuel.

What role do safety switches play in startup?

Safety switches prevent the motor from running if the trigger, wand, or gun isn’t engaged correctly. Ensure they move freely and are not stuck, and replace worn switches if needed.

Safety switches ensure you actively engage the trigger to start the motor.

When should I see a technician?

If basic steps don’t resolve the issue, internal pump, carburetor, or electrical faults may require specialized tools. A technician can diagnose and repair safely.

If basic fixes don’t work, a technician can diagnose deeper problems.

How can I prevent startup problems in the future?

Follow a simple maintenance routine: store fuel properly, run the unit dry after use, replace worn hoses and nozzles, and perform regular oil and filter changes on gas models.

Regular maintenance reduces the likelihood of startup problems.

Watch Video

Key Takeaways

- Confirm power and safety basics first.

- Gas vs electric startups require different checks.

- Fresh fuel and clean carbs prevent start failures in gas units.

- A good water supply is essential for operation.

- Call a pro if the problem persists after basic steps.