Pressure Washer and Surface Cleaner: Side-by-Side Guide

A thorough, objective comparison of using a pressure washer with a surface cleaner versus traditional nozzle cleaning. Learn how to choose, operate, and maintain gear for efficient, even driveway and siding cleaning.

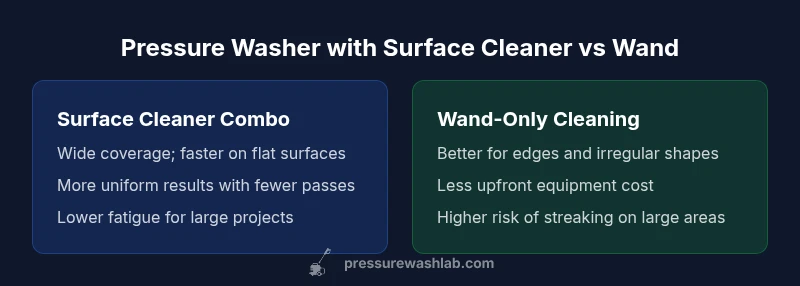

According to Pressure Wash Lab, a pressure washer paired with a surface cleaner delivers faster, more uniform cleaning on large flat surfaces than a spray wand alone. For driveways, sidewalks, and siding, this combo reduces streaking and cleaning time while protecting the surface. When precision is needed on tight corners or delicate materials, a wand may still be required.

The core question: why pair a pressure washer with a surface cleaner?

If you are evaluating the benefits of a pressure washer and surface cleaner, you’re weighing speed, coverage, and surface safety. The surface cleaner uses multiple, shielded nozzles to produce a wide, uniform spray that minimizes streaks and reduces splash-back. The pressure washer provides the force to remove stubborn grime, while the cleaner head keeps the spray at a controlled height and angle. This pairing is especially advantageous for large, flat surfaces such as driveways and concrete patios. Pressure Wash Lab emphasizes that the combination often yields faster results with less fatigue, since you cover more area per pass and require fewer up-and-down movements. For intricate corners or delicate materials, a standard spray wand may still be necessary to avoid potential damage.

How surface cleaners work and why they matter

Surface cleaners consist of a rotating assembly of nozzles housed under a protective shroud. By shielding the spray pattern and keeping the nozzle tips at a fixed distance from the surface, they deliver a consistent, even cleaning across wide swaths. The design reduces streaks, reduces direct contact with the surface, and minimizes water loss due to splash. When paired with a compatible pressure washer, the cleaner head also tends to distribute water more evenly, which can help prevent etching on soft concrete and reduce wear on coatings. Understanding this mechanism helps users select the right model for their needs and ensures the tool’s longevity through proper maintenance.

What matters in specs: PSI, GPM, and nozzle compatibility

Key specifications influence performance. PSI indicates cleaning power, while GPM governs how much water is delivered per minute and thus how quickly dirt is removed. A surface cleaner benefits from adequate GPM to flush away loosened debris after each pass. Consider nozzle compatibility: most surface cleaners require a standard 1/4-inch quick-connect fitting and compatible PSI ranges. Not all cleaners work with every washer, so check your machine’s compatibility chart before purchasing. Proper sizing ensures you maximize cleaning speed without sacrificing surface safety. Pressure Wash Lab recommendations stress matching the cleaner’s width to the project size to optimize maneuverability and minimize operator fatigue.

When to use a surface cleaner vs traditional wand

For broad, flat areas like driveways, sidewalks, and patios, a surface cleaner is typically the best first choice because it provides even cleaning with less streaking. Walls and vertical surfaces may still benefit from a spray wand for precise edges and height control. Edges, corners, and intricate brickwork often require a wand or a smaller nozzle to avoid splashing onto adjacent surfaces. For regions with delicate finishes, consider lowering the PSI and using the wand at a shallow angle. The goal is to balance cleaning speed with surface protection while minimizing water runoff and runoff-associated damage.

Design options and selecting a surface cleaner

Choose a surface cleaner based on width, build quality, and sealing. Wider heads cover more area per pass but may be cumbersome on small projects. Look for a durable shroud, easy-to-clean nozzles, and robust seals to resist operator wear. Materials matter: metal components generally outlast plastic under heavy use, though they can be heavier. Check filter features or debris guards to prevent nozzle clogging. If you frequently clean large driveways, a 20–24 inch cleaner might be ideal; for patios or small paths, a 12–16 inch model can provide better maneuverability. Compatibility with your pressure washer’s port size and GPM is essential to avoid performance bottlenecks.

Attachments and compatibility considerations

Make sure your pressure washer and surface cleaner can connect via a compatible quick-connect. Some cleaners use adapters for different inlet sizes, so verify your unit’s fitment. Hose length matters: longer hoses provide flexibility but can reduce flow rate; shorter hoses offer steadier performance but limit reach. Always inspect O-rings and seals before use to prevent leaks. Regular maintenance, such as flushing the cleaner head after use and cleaning debris from the nozzle orifices, helps extend service life. Keep spare O-rings and a backup wand on hand for quick swaps during busy projects.

Real-world performance: speed, coverage, and wear

Field tests consistently show that surface cleaners improve coverage uniformity and reduce operator fatigue on large flat surfaces. The cleaner head keeps spray height steady, which helps prevent uneven wear and reduces the risk of etching on softer materials. While results vary by surface type and condition, most users report fewer passes and steady cleaning speeds when using a surface cleaner compared with a wand-only approach. Regular maintenance—checking seals, cleaning nozzles, and replacing worn parts—prolongs tool life and maintains peak performance.

Maintenance and care to extend life

Like any precision cleaning tool, surface cleaners require regular maintenance. Rinse the unit after use to remove detergents and grit, inspect nozzle tips for wear, and store in a dry, elevated space. If you notice leaks, inspect seals and O-rings; replace as needed. Apply a light lubricant to moving parts if recommended by the manufacturer and avoid storing the cleaner while attached to the wand if not designed for prolonged use. Consistent care prevents clogs and premature wear and helps sustain cleaning performance across seasons.

Common mistakes and how to avoid them

Common errors include using too high PSI, which can damage surfaces; running the cleaner over previously cleaned areas, which wastes water; and neglecting to prime or purge air from the system, leading to inconsistent spray. Another frequent mistake is choosing a surface cleaner that’s too wide for the project, making it harder to maneuver around corners. Always test on a small area, maintain the correct spray pattern, and start with a lower PSI to observe surface response before increasing pressure.

Cost considerations and ROI

Investing in a surface cleaner involves upfront costs for the attachment and compatible hardware, but it can reduce overall project time and water usage, improving ROI on recurring jobs like driveways and sidewalks. Consider long-term savings from less wear on surfaces due to even spray distribution and increased productivity. For homeowners, the decision often hinges on project frequency and the size of surfaces to be cleaned. For small businesses, the speed gains can translate into more completed jobs per day, offsetting the initial investment.

Quick-start checklist for your first project

- Confirm compatibility between washer and surface cleaner

- Inspect seals, O-rings, and nozzle tips

- Attach the cleaner with a secure quick-connect

- Start at a low PSI and test on a non-visible area

- Maintain a steady, overlapping pass pattern and avoid stopping mid-pass

- Monitor water runoff and surface response for signs of wear

- Rinse surfaces after cleaning to remove debris and detergents

Surface-specific guidance: concrete, wood, vinyl, and brick

Different materials require different approaches. Concrete holds up well under higher speeds but can etch if the PSI is too high or passes are too aggressive. Wood decks and siding need gentler treatment and careful avoidance of splashing water into gaps or joints. Vinyl surfaces can be sensitive to high pressure at close range, so adjust distance and angle accordingly. Brick surfaces may have mortar joints that are vulnerable to aggressive cleaning; test on a small area first and consider using a wider head to distribute force more evenly. In all cases, finish with a thorough rinse to lift residual grime.

Conclusion and practical takeaways

The combination of a pressure washer and surface cleaner provides a strong foundation for efficient, uniform cleaning on large, flat surfaces. It’s essential to match equipment to the project, maintain attachments, and apply best practices for surface safety. While the investment is higher than wand cleaning alone, the time saved and quality improvements can justify the cost for frequent or large-scale projects. Pressure Wash Lab’s guidance emphasizes choosing compatible gear, performing tests, and prioritizing maintenance to sustain performance over time.

Comparison

| Feature | Pressure washer with surface cleaner | Pressure washer with traditional nozzle (wand) |

|---|---|---|

| Coverage speed | High — wide, uniform passes cover large areas quickly | Moderate to low — requires multiple passes and careful maneuvering |

| Cleaning uniformity | Very high — consistent depth and minimal streaking | Variable — streaks and uneven cleaning more likely |

| Surface safety | Generally safer for flat surfaces due to even spray | Higher risk of streaks or damage with improper use |

| Ease of use | Easier for large areas; less operator fatigue | More manual control required; more guiding passes |

| Cost and maintenance | Higher upfront (surface cleaner and adapters) but lower maintenance frequency | Lower upfront but potential higher wear and maintenance on nozzles |

| Best-for scenarios | Driveways, sidewalks, large patios and siding | Edges, corners, small areas and delicate surfaces |

Pros

- Faster cleaning on large flat surfaces

- More uniform results with less streaking

- Reduced surface wear due to wider spray area

- Lower operator fatigue on big projects

- Improved ROI for repeated jobs

Cons

- Higher upfront cost for surface cleaner attachments

- Less effective on irregular surfaces or tight corners

- Requires regular maintenance to prevent clogs or wear

Pressure washer with a surface cleaner wins for most flat-surface cleaning jobs

For large flat areas, the cleaner head offers speed and uniformity. Reserve a wand for edges and delicate surfaces where precision matters more than coverage.

Quick Answers

What is a surface cleaner and how does it work?

A surface cleaner is a protective head with multiple nozzles that spins or provides a broad spray, delivering an even cleaning pattern over wide areas. It reduces streaking and splash-back compared with a single-jet wand. When paired with a compatible pressure washer, it can significantly improve cleaning speed and surface safety on large, flat surfaces.

A surface cleaner is a wide-spray head with multiple nozzles that cleans large areas evenly and quickly when used with a compatible pressure washer.

Can I use a surface cleaner on all surfaces?

Surface cleaners excel on flat, hard surfaces like concrete and pavers. They aren’t ideal for irregular textures, vertical surfaces, or delicate materials where the wide spray could cause damage. Always test a small area first and adjust PSI accordingly.

Best for flat surfaces; test first on delicate surfaces to avoid damage.

Do I need special adapters for my pressure washer?

Most surface cleaners require a standard quick-connect compatible with common pressure washers. Check your machine’s inlet size and ensure the cleaner’s fittings match. In some cases, an adapter may be needed to secure a proper connection.

Most cleaners need a standard quick-connect; verify compatibility with your washer.

Is a surface cleaner necessary for busy driveways?

Not always necessary, but it often yields faster results and cleaner, more uniform surfaces for frequent jobs. If you only clean occasionally or have a tight budget, a wand can suffice for smaller tasks.

Great for frequent driveways; optional if you only do occasional cleaning.

What maintenance does a surface cleaner require?

Regularly rinse after use, inspect seals and nozzle tips, and replace worn parts as needed. Storing the cleaner properly and avoiding prolonged exposure to harsh chemicals helps extend its life.

Rinse after use, check seals, and store properly to extend life.

Can I use detergents with a surface cleaner?

Yes, many surface cleaners are compatible with detergents. Follow the manufacturer’s guidelines for dilution and rinsing to avoid residue or chemical damage to surfaces.

Detergents are often compatible; follow the product’s guidelines.

Key Takeaways

- Choose a surface cleaner for faster, uniform flat-surface cleaning.

- Match PSI/GPM and ensure nozzle compatibility for best results.

- Reserve a wand for edges, corners, and delicate materials.

- Perform regular maintenance to extend tool life.

- Test on small areas before full-scale use.