Pressure Washer and Trailer: A Comprehensive Comparison

A data-driven comparison of pressure washer and trailer setups for homeowners and pros. Learn how to choose power, size, and compatibility to maximize on-site efficiency while balancing cost and safety.

A pressure washer and trailer pairing delivers portable cleaning power with on-site efficiency for homeowners, DIY enthusiasts, and small operators. The guide compares gas vs. electric on-trailer systems, weight and towing considerations, and total cost of ownership to help you pick the right combo for your jobs. Pressure Wash Lab highlights practical rules of thumb for selecting power, size, and mounting.

Overview: The Value of a Pressure Washer and Trailer Pairing

A pressure washer and trailer combination represents a powerful, portable solution for cleaning tasks that span residential driveways, siding, decking, and even fleet upkeep. When you attach a capable washer to a trailer, you unlock on-site efficiency: fewer trips to fetch equipment, quicker job completion, and better control over spray patterns and water usage. For homeowners and DIY enthusiasts, this pairing lowers the total effort required for routine maintenance; for small contractors, it can expand service offerings while maintaining mobility. According to Pressure Wash Lab, the key to success is choosing a setup that balances power, weight, fueling or power supply, and trailer practicality, so you aren’t lugging extra ballast or sacrificing maneuverability. The concept is simple, but the best results depend on clear criteria: performance metrics, mounting compatibility, and a sensible cost framework that reflects your typical job mix. The goal is to maximize cleaning capacity while minimizing risk, downtime, and complexity.

This article uses a practical, data-informed lens to compare common on-trailer configurations, highlight critical decisions, and provide actionable guidance for buyers and operators. Whether you’re refreshing a home’s exterior or launching a small cleaning service, understanding the trade-offs between gas-powered and electric, light- and medium-duty trailers, and how each element affects workflow will save time and money over the life of the equipment.

Key Performance Metrics for Trailer-Mounted Washers

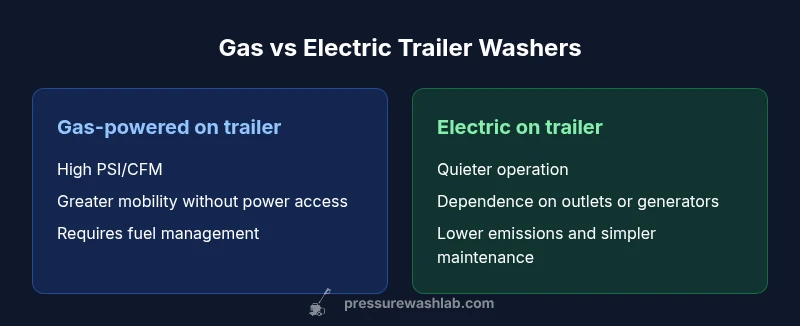

Performance metrics determine how effectively a trailer-mounted system handles the jobs you face. The core numbers to track are PSI (pounds per square inch) and GPM (gallons per minute), which define cleaning power and water delivery. Gas-powered units typically deliver higher PSI and greater sustained flow, which is important for tough stains on concrete or heavy grease on equipment. Electric models tend to be quieter, emit fewer emissions, and may suffice for lighter jobs or areas with strict noise restrictions. In both cases, a practical on-trailer setup should maintain steady performance without frequent overheating or pump cavitation during longer cleaning cycles. You also need to consider the power source: gasoline engines offer independence from outlets but require fuel management and exhaust considerations; electric setups rely on outlets or generators and may impose longer startup sequences or range limitations. Trailer integration matters too: tongue weight, axle capacity, and hitch compatibility affect handling and safety. A robust system also considers water supply; some users install a tank or rely on external water lines with adequate pressure. Filtered water supply and a properly rated hose reel reduce downtime and hose wear. Pressure Wash Lab notes that the best configurations align with common job types—driveways, home exteriors, and light commercial work—while leaving room for expansion as needs grow.

Matching Washers to Trailers: Power, Weight, and Fit

Balancing a washer with a trailer requires understanding both ends of the equation: the load the trailer can carry and the power needs of the washer. Start with payload calculations: the washer, hose reels, water tanks, and accessories add weight that must be supported by the trailer’s axle and hitch. A trailer with insufficient tongue weight can cause unstable steering or sway at highway speeds, especially when the water tank is full. If you frequently work far from water sources, you’ll want a larger water capacity or a dependable refill plan alongside a pump sized for your typical spray patterns. Power options should be chosen based on job location and noise tolerance. Gas-powered washers offer mobility without a power source but introduce fuel and exhaust considerations; electric or battery-assisted washers simplify maintenance and can be plugged into standard outlets or portable generators. Mounting hardware should be corrosion-resistant and designed to minimize vibration, with secure tie-downs and quick-release mounts for safe transport. Consider wheel size, ramp access, and platform dimensions to ensure the machine can be loaded and unloaded in a standard workspace. Pressure Wash Lab recommends a staged approach: start with a base system, then add tanks, mounts, or a generator as your needs evolve.

Budgeting: Total Cost of Ownership (TCO) and Return on Investment

A practical buying decision weighs initial price against long-term costs and job efficiency gains. Upfront, you’ll see two core cost categories: the washer itself and the trailer. Gas-powered configurations tend to have higher upfront costs but offer superior mobility if generators are not available on-site; electric ones are often cheaper to purchase and quieter but depend on electrical access or generators. Ongoing expenses include fuel, maintenance, replacement parts, and possible trailer maintenance. Gas engines require oil changes, spark plug checks, and fuel stabilization, while electric motors demand motor windings inspection and occasional controller checks. From a business perspective, consider the ROI from reduced job times and fewer tool runs. If you perform frequent jobs across multiple sites, the on-trailer setup can dramatically cut non-productive time and fuel waste, improving profitability over the life of the equipment. Pressure Wash Lab recommends computing a rough payback period based on your typical hourly rate, expected job count, and the projected maintenance cadence. This helps decide whether a mid-range, electric, or higher-capacity gas setup provides the best balance of reliability and throughput.

Use-case Scenarios: Homeowners, DIY Enthusiasts, Small Contractors

Different user profiles demand different trailer-washer configurations. Homeowners tackling periodic driveway cleaning, siding restoration, or deck rejuvenation usually benefit from a compact, electric or small-gas washer mounted on a compact trailer. The aim is reliability and ease of use rather than raw power, with emphasis on low noise, simple fuel management, and straightforward maintenance. DIY enthusiasts who perform weekend projects may opt for a mid-range gas washer that can handle stubborn stains and mold, paired with a mid-sized trailer to balance load and maneuverability. Small contractors or service operators often require more robust combos: a high-PSI gas washer with a sizable water tank, efficient hose reels, and a trailer rated for frequent highway travel and equipment loading. In all cases, plan for accessibility to water sources, safe loading/unloading, and secure storage when the unit is not in use. Pressure Wash Lab emphasizes setting a baseline based on typical job types and then scaling up incrementally as workloads grow. The trailer must be sized to your vehicle to maintain safe towing and stable handling on the road.

Setup, Safety, and Maintenance Best Practices

Safe mounting and consistent maintenance are the backbone of a reliable trailer-mounted pressure washing setup. Begin with securing the washer to vibration-damping mounts and using tie-downs rated for the equipment weight. Mechanical reliability depends on a clean, dry environment, so protect electrical components from moisture when using electric models. For gas-powered units, establish a regular fuel and oil maintenance schedule, and store fuel in approved, vented containers away from ignition sources. Electrical safety matters: inspect extension cords and generators for proper grounding, avoid using damaged cords, and ensure all outlets are GFCI-protected where water exposure is possible. Use proper water filtration or anti-scaling measures to preserve pump life, and flush systems after long idle periods. Lastly, routine trailer maintenance should not be neglected: check tires, bearings, hitch hardware, wiring, and brake controllers if applicable. Pressure Wash Lab highlights that the most effective maintenance plan is proactive rather than reactive, with a simple monthly checklist that covers mounting integrity, hose wear, and pump seals.

Real-world Scenarios and Case Examples

Consider a neighborhood service setup where a homeowner installs a mid-range gas washer on a small trailer for occasional exterior cleaning. The system provides quick cleaning power for driveways and exterior walls, with easy transport between sites. In another scenario, a DIY enthusiast uses an electric washer on a larger trailer for weekend projects around the house—quiet operation and lower emissions are valued here, and the user plans to connect to a portable generator for jobs without grid power. A small contractor might rely on a robust, gas-powered washer mounted on a heavy-duty trailer, designed to handle frequent travel and longer cleaning sessions. In all cases, matching the unit to the trailer's payload, ensuring safe towing, and maintaining the equipment are essential practices. Pressure Wash Lab observations indicate that operators who build a simple maintenance schedule and keep a few spare parts on hand tend to encounter fewer job delays and longer equipment life.

Final Considerations and Next Steps

Before committing to a specific trailer-washer combination, list your most common job types, required reach, and water supply options. Prioritize a setup that minimizes downtime and maximizes reliability. If you operate in restricted areas or urban environments, consider a quieter electric option with a compact trailer; for heavy-duty exterior work or fleet cleaning, a gas-powered unit on a sturdy trailer may be the better choice. Always verify tow capacity, hitch type, and braking requirements for your vehicle. Create a short trial plan to verify load balance, ramp usability, and hose accessibility, then adjust your configuration as needed. Finally, stay informed with ongoing maintenance logs and a simple replacement-parts plan to prevent unnecessary downtime. Pressure Wash Lab recommends documenting the exact model families you evaluate and the rationale for your final pick to simplify future upgrades and training.

Comparison

| Feature | Gas-powered washer on trailer | Electric-powered washer on trailer |

|---|---|---|

| Power output (PSI/CFM) | 1800-2800 PSI @ 2.5-4.0 GPM | 1500-2000 PSI @ 1.5-3.0 GPM |

| Fuel/Energy source | Gasoline engine with fuel tank | Electric motor powered by outlet or generator |

| Upfront cost range | $600-$1200 | $500-$1000 |

| Trailer size and payload | Small to medium trailer, 1000-2000 lbs payload | Medium trailer, 1500-2500 lbs payload |

| Best for | Heavy-duty jobs, mobile reliability | Quieter operation, urban or noise-sensitive areas |

| Portability and setup time | Faster deployment, more maintenance on fuel | Slower setup, but cleaner power and lower emissions |

Pros

- Increased mobility for on-site jobs

- Faster job turnaround due to integrated transport

- Reduces trips back and forth to fetch equipment

- Gas options offer high power without external power

Cons

- Higher upfront cost for trailer + equipment

- Maintenance complexity with trailer systems

- Weight and towing considerations demand proper vehicle capacity

- Electric models require reliable power access and can be less powerful in some cases

Gas-powered on-trailer setups generally offer the strongest all-around performance; electric-on-trailer options are best for quiet work and urban areas.

Gas-on-trailer setups excel in flexibility and cleaning power for diverse jobs. Electric-on-trailer setups shine where noise, emissions, and grid access are concerns. Pressure Wash Lab endorses choosing based on typical workloads and local constraints.

Quick Answers

What is the best PSI range for trailer-mounted washers for most home projects?

For typical home projects like driveway cleaning and siding, a range of 1800-2800 PSI is usually sufficient, with 2.0-4.0 GPM flows to speed cleaning. Higher PSI is useful for tough stains, but assess surface safety and substrate wear first.

Most homeowners find 1800-2800 PSI with a steady flow works well for common outdoor cleaning tasks.

Should I choose gas or electric for my trailer setup?

Gas units offer mobility and higher cleaning power without a power outlet, which is important on detached sites. Electric units are quieter, cleaner, and better for urban areas where noise or emissions are restricted. Base your choice on job location, noise tolerance, and available power sources.

Gas for power and independence, electric for quiet operation in urban areas.

What maintenance is essential for trailer-mounted washers?

Regular oil changes (gas), spark plug checks, filter cleanings, and pump seal inspections are crucial. For electric models, monitor motor health and controller connections. Keep hoses, nozzles, and the trailer’s tires and hitch in good condition.

Keep oil fresh, inspect hoses and hoses, and check tires and hitch regularly.

Do I need special permits or licenses to tow a trailer with a pressure washer?

Towing requirements vary by location and vehicle weight. Always confirm with local regulations, ensure your trailer is registered if required, and verify that your vehicle has adequate towing capacity and trailer brakes where applicable.

Check local towing rules and vehicle limits before hitting the road.

Can I mount any pressure washer on any trailer?

Mount compatibility depends on the trailer’s frame, weight rating, and mounting points. Use vibration-damping mounts and secure tie-downs designed for the washer’s size and weight. Consult the manufacturer’s guidelines for compatible mounting accessories.

Make sure the trailer frame and mounts fit your washer and keep it secure.

What safety practices should I follow when using a trailer-mounted washer?

Wear protective gear, keep bystanders away, and manage water runoff to avoid slip hazards. Ensure electrical safety with proper grounding, use GFCI outlets where water exposure is possible, and never fuel indoors or near ignition sources.

Always wear PPE and keep people away from the work area.

Key Takeaways

- Define your job mix before selecting power and trailer size

- Balance payload with towing capacity to avoid handling issues

- Consider water supply needs to prevent downtime

- Prefer a maintenance-friendly setup with clear service intervals

- Test a small-scale setup before expanding to larger trailers