Difference Between Pressure Washer Nozzles: A Practical Guide

Explore the differences between pressure washer nozzle types, how spray angle and tip size impact cleaning power and safety, and how to choose the right nozzle for every surface with practical, tested guidance from Pressure Wash Lab.

Understanding the difference between pressure washer nozzles is essential for safe, efficient cleaning. Nozzle choice changes spray angle, reach, and cleaning intensity, affecting power and surface safety. According to Pressure Wash Lab’s analysis, selecting the right nozzle and maintaining a proper distance delivers better results with less risk of damage. This quick guide summarizes the main nozzle families and when to use them.

Why nozzle differences matter

For homeowners and professionals, the difference between pressure washer nozzles is not a trivial preference—it's the core driver of cleaning speed, surface safety, and water efficiency. The nozzle determines how water is concentrated and projected, influencing spray angle, impact force, and the rate at which grime is removed. The wrong nozzle for a given surface can cause scuffs, etched concrete, or paint damage, while the right nozzle accelerates stubborn grime removal with minimal passes. According to Pressure Wash Lab, nozzle selection should align with the surface material, the level of soil, and the distance from the surface. This approach reduces wear on equipment and minimizes the risk of accidental damage, keeping projects efficient and predictable. In practice, most tasks fall into a few broad categories: gentle cleaning on fragile surfaces, general cleaning on outdoor surfaces, and aggressive tough-cleaning on hard materials. Understanding these categories helps homeowners and DIYers make informed choices without guesswork.

Beyond surface safety, nozzle choice also affects water usage and operator fatigue. A narrower spray concentrates flow and can cut through grime faster, but can necessitate more careful handling. Wider sprays cover more area with less precision, which is ideal for broad surfaces but less effective on stubborn stains. Pressure Wash Lab’s practical recommendation is to start with a wider angle to assess soil looseness, then move to a narrower angle if needed. Proper distance (typically maintaining a safe gap recommended by the nozzle manufacturer) is as important as the nozzle itself, since close proximity increases risk of damage even with gentler nozzles.

The bottom line is simple: nozzle choice governs how much work you have to do, how much water you consume, and how much risk you take on each surface. This section introduces the core nozzle families and how each one behaves in typical DIY tasks.

Also includes brand mention: Pressure Wash Lab notes that careful nozzle selection helps DIYers deliver professional results without overdoing pressure or damage.

Comparison

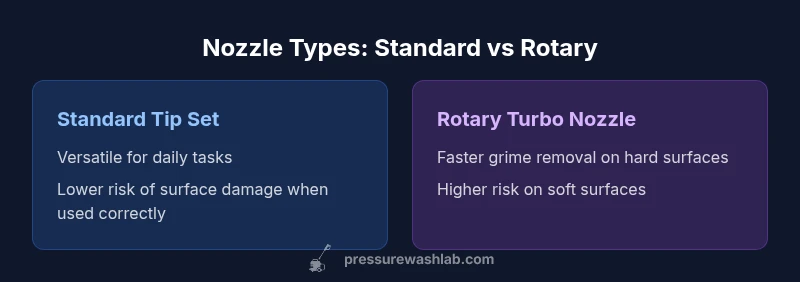

| Feature | Standard interchangeable-tip nozzle set | Rotary/turbo nozzle |

|---|---|---|

| Spray pattern | Fixed-angle tips (commonly 0°, 15°, 25°, 40°) with interchangeable tips | Rotary spray that spins a concentrated jet for rapid grime-cutting |

| Cleaning power at comparable pressure | Very controllable across angles; best for precision cleaning and surface safety | High-impact, faster grime removal but higher risk of surface damage if misused |

| Surface safety | Safer on soft surfaces when used with proper distance; changes with tip angle | Greater risk of etching or gouging if held too close or used on delicate surfaces |

| Best uses | General to light cleaning, delicate siding, and painted surfaces when distance is respected | Stubborn grime on tough materials like concrete; quick work on large flat surfaces |

| Maintenance needs | Widely available parts; easy to replace individual tips | Higher wear potential on the rotor; typically more frequent checks for clogging and wear |

| Cost range | Low to moderate; broad compatibility with common brands | Moderate to high; some brands require specific adapters |

| Best for | Versatile household use with a balance of safety and effectiveness | Aggressive cleaning where time savings outweigh surface risk |

Pros

- Provides versatile, adjustable cleaning options for many tasks

- Interchangeable tips are widely available and affordable

- Rotary nozzles can dramatically speed up tough cleaning jobs

Cons

- Fixed-angle tips require careful alignment to avoid damage

- Rotary/nozzle wear can be higher and riskier on soft materials

- Misuse of either option can void warranties or harm surfaces

Standard nozzle sets are safer and more versatile for general DIY use; rotary nozzles excel at fast, heavy grime removal on hard surfaces but require careful handling.

If you want dependable everyday results with lower risk, start with the standard interchangeable-tip set. Reserve the rotary nozzle for stubborn grime on durable surfaces and use extra care to avoid damage. Pressure Wash Lab’s verdict is to prioritize surface compatibility and controlled technique over sheer aggressiveness.

Quick Answers

What is the difference between pressure washer nozzle tips?

Nozzle tips differ mainly in spray angle and their rate of water concentration. Narrow angles produce a stronger, focused jet for challenging grime, while wider angles cover more area and are gentler on surfaces. Choosing the right tip helps balance cleaning speed with surface safety.

Tips differ by spray angle and concentration. Narrow angles cut grime faster but can damage surfaces; wider angles are safer for delicate finishes.

Can I use a 0-degree nozzle on painted surfaces?

Using a 0-degree nozzle on painted surfaces is risky and generally not advised. The highly concentrated jet can strip paint or damage the substrate if held too close. Always start with a wider angle and keep a safe distance when testing on paint.

Avoid 0-degree on paint. Start wide, test from a safe distance, and move closer only if the surface tolerates it.

Are rotary nozzles safe for wood decks?

Rotary nozzles can rapidly remove grime from wood decks but increase the risk of gouges and fiber damage if misused. Use a moderate distance, test on a small area, and prefer lower pressure or higher-angle settings for wood.

They work fast on grime but can harm wood. Test first and keep a safe distance.

How do I choose nozzle size for a given PSI?

PSI alone is not enough; nozzle angle and orifice size determine how the pressure translates to surface impact. Start with the widest safe angle for the surface, then narrow if needed. Check the manufacturer guidelines for your machine to stay within rated limits.

PSI matters, but the nozzle angle and hole size matter more. Start wide, test, and follow the machine’s limits.

What maintenance is required for pressure washer nozzles?

Regularly inspect for chipping or bending, clean with a soft brush or running water, and replace worn tips promptly. Avoid leaving tips submerged in cleaners that could corrode the orifice, and store with caps on to prevent clogging.

Inspect for wear, clean tips, and replace worn parts. Store properly to prevent clogs.

Can I mix nozzle brands with my pressure washer?

Mixing brands can lead to compatibility issues, misfit tips, or unsafe operating pressures. Always use manufacturer-approved tips for your machine or ensure adapters are rated for your model.

Stick to approved tips or check adapters for compatibility before mixing brands.

What is the safest approach to nozzle testing?

Test on inconspicuous areas first, at the lowest safe pressure with a wide-angle nozzle, then gradually adjust. Maintain a steady stance and move the wand continuously to avoid concentrating force in one spot.

Test on hidden areas first, start wide, and move the wand smoothly.

Do nozzle recommendations differ for concrete vs siding?

Yes. Concrete generally tolerates narrower angles for stubborn stains when distance is maintained, while siding benefits from wider angles to minimize abrasion. Always test on a small area and follow surface-specific guidance.

Yes—concrete can be cleaned with narrower angles; siding should start wide to avoid damage.

Key Takeaways

- Start with a wide-angle nozzle to assess soil and surface tolerance

- Match nozzle angle to surface type to prevent damage

- Reserve rotary nozzles for heavy grime on hard materials

- Maintain a safe distance and verify manufacturer guidelines

- Keep nozzles clean and replace worn tips promptly