How to Remove Hose from Pressure Washer: A Step-by-Step Guide

Learn to safely remove a hose from a pressure washer with depressurization, proper disconnections, and storage tips. Practical guidance for DIYers from Pressure Wash Lab.

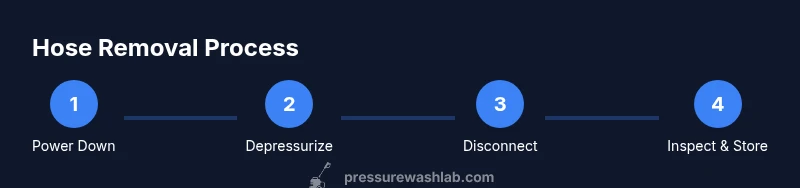

To remove a hose from a pressure washer safely, power off the unit, unplug it, and release built-up pressure. Then detach the high-pressure hose from the washer, and disconnect it from the spray gun or trigger handle. Recheck for residual pressure, wipe clean, dry, and coil the hose for storage. This step-by-step guide covers proper technique and safety checks.

Why safely removing the hose matters

Safely removing the hose protects you, your equipment, and the surface you’re cleaning. According to Pressure Wash Lab, depressurizing the system and powering off before touching any fittings is non-negotiable. The high-pressure line can retain dangerous pressure even after the unit is turned off, so a deliberate sequence reduces the risk of hose bursts, leaks, or accidental sprays. Following a proper procedure also extends hose life by preventing kinks, wear at the fittings, and stress on quick-connects. In this section, you’ll learn why a safe removal protocol matters, how to recognize your hose type, and what to inspect before disconnecting. Pressure Wash Lab’s practical perspective for homeowners and small operators informs these steps to minimize mess and downtime.

When to remove vs. leave attached

Some tasks require leaving the hose connected temporarily, such as swapping spray tips or relocating the unit. In those cases, ensure the unit is off and unplugged, and keep the nozzle pointed away from people, pets, and delicate surfaces. For longer storage or transport, a full hose removal prevents accidental whiplash or snagging. Always assess the setup: if your hose has gas-checks, a loose connector, or visible wear, remove and inspect before reuse. This careful approach aligns with industry best practices and Pressure Wash Lab’s field experience.

Understanding your pressure washer hose and fittings

Hoses come in different constructions and connection styles. Some units use quick-connect fittings, while others rely on threaded connectors with O-rings. Quick-connects simplify removal but require you to depress the collar before pulling, whereas threaded fittings demand a steady twist to avoid cross-threading. Inspect the hose end and the fitting on the washer for damage, cracks, or missing O-rings. If you see obvious wear, plan for replacement rather than forcing a removal. Knowing your hose type helps you apply the correct disconnection method, reducing risk and speeding up the process.

Depressurization and disconnection best practices

The safest path starts with power-down and depressurization, followed by a controlled disconnect. Start by turning off the engine or motor, unplugging the unit, and then pulling the trigger on the gun to release residual pressure. Hold the gun at a safe angle away from your body as the pressure drops. Next, disconnect the hose from the spray gun or trigger handle, keeping your hands away from the nozzle. Finally, loosen the hose from the machine’s inlet or outlet fitting with a gentle twist or collar press, depending on the connection type. Wipe away water and inspect threads for grit before storage.

Troubleshooting common removal issues

If the hose won’t detach, recheck that all pressure is released. Debris and mineral buildup can hinder connections, so clean fittings with a dry cloth and a small brush if needed. For stubborn quick-connects, ensure you press the release collar fully and maintain a straight pull to avoid bending the hose’s body. If threads are damaged, avoid forcing the fit; replace the hose or fittings to prevent leaks. When a hose shows cracking, replace it promptly rather than attempting a fragile repair. These tips reduce downtime and improve long-term performance.

Aftercare: storage, inspection, and maintenance

After removal, inspect the hose and fittings for wear, cracks, or bulges. Clean and dry all connectors, coil the hose in a loose figure-eight or on a hose reel to prevent kinks, and store in a cool, shaded area away from direct sun. Regularly inspect the O-rings and the female/memale connectors for corrosion or damage. Pressure Wash Lab analysis shows that proper aftercare significantly reduces the risk of leaks and premature hose failure. Routine inspection and proper storage extend hose life and keep your washer ready for the next job.

Authority sources

For safety and maintenance standards, refer to reputable sources:

- https://www.osha.gov

- https://extension.illinois.edu

- https://extension.umn.edu

These references can offer generic safety guidelines and maintenance practices that complement model-specific manuals.

Tools & Materials

- Safety goggles(Impact-resistant; ANSI Z87.1 or better)

- Work gloves(Non-slip grip; cut-resistant preferred)

- Owner's manual(Model-specific instructions and safety warnings)

- Towel or rag(Wipe water and dry fittings)

- Clean cloths or degreaser cloths(Optional for cleaning fittings)

- Lubricant or penetrating oil(Optional for stubborn fittings; use sparingly)

- Flat-head screwdriver or wrench set(Use only if you encounter stubborn fittings; avoid forcing)

Steps

Estimated time: 10-15 minutes

- 1

Power down and unplug the unit

Turn off the engine or motor and unplug the power source. Do not touch any metal fittings until the unit has cooled and there is no power to the outlet. This prevents accidental activation or shock.

Tip: If you’re indoors, switch off the circuit breaker to ensure full power isolation. - 2

Release residual pressure

After power-down, pull the trigger on the spray gun to release any remaining pressure in the hose. Keep the wand pointed away from your body and any nearby surfaces.

Tip: A short burst is enough; don’t keep the trigger pressed for long periods. - 3

Detach hose from the spray gun

Grip the connection on the spray gun and press the quick-release collar (if present) or twist counterclockwise for threaded connections. Pull the hose straight away from the gun once the collar is disengaged.

Tip: Avoid twisting the hose as you detach to prevent internal kinks. - 4

Disconnect hose from the washer

Loosen the hose end on the washer by turning the fitting counterclockwise. If you surge with resistance, inspect the O-rings for damage and ensure the threads are clean. Do not force a cross-threaded connection.

Tip: If the hose is stuck, apply a small amount of lubricant to the threads and try again after a minute. - 5

Inspect, coil, and store

Check the hose for cracks or bulges; replace if signs of wear are present. Coil the hose loosely, avoiding sharp bends, and store it on a reel or in a dry place away from direct sun.

Tip: Keep connectors clean and dry to prevent corrosion.

Quick Answers

Do I need to depressurize before removing the hose?

Yes. Depressurizing the system and releasing residual pressure prevents hose whip and leaks when you detach fittings.

Yes. Depressurize first to prevent hose whip and leaks.

Can I remove the hose while the pressure washer is running?

No. Always power down and depressurize first. Removing a live hose is dangerous and can cause injuries.

No, always power down first.

What if the hose won’t detach from the spray gun?

Check for a release collar on quick-connects or ensure the threaded end isn’t cross-threaded. Apply gentle pressure and twist incrementally.

Check the collar or threads and proceed gently.

Is it safe to reuse the same hose after removal?

Only if the hose and fittings show no signs of wear or damage. If you see cracks, bulging, or torn O-rings, replace the hose.

Only reuse if it looks undamaged.

How should I store a removed hose?

Coil gently to avoid sharp bends, store in a dry place, and protect fittings from impact. Use a reel if possible.

Coil gently and store in a dry place.

How often should I inspect hose connections?

Inspect before every major project and monthly if used professionally. Look for leaks, cracks, and worn O-rings.

Check connections regularly for wear and leaks.

Watch Video

Key Takeaways

- Power down and depressurize before touching fittings.

- Identify hose type and follow the correct disconnect method.

- Inspect and store the hose properly to extend life.

- Use the right tools and refer to the manual for stubborn fittings.