How to Store a Pressure Washer for Winter: A Practical Guide

Learn how to store your pressure washer for winter with a practical, step-by-step approach. This guide covers prep, draining, fuel management, drying, and safe storage to protect pumps, hoses, and seals.

Steps to store a pressure washer for winter: cool the unit, drain water from the pump and hoses, flush and clean, remove fuel or stabilize, dry all parts, and store off the ground in a dry, ventilated space. Perform a quick pre-use check before the next season to ensure seals and hoses are ready.

Why winter storage matters

Winter storage is more than just tucking your tool away; it's a protection plan for the pump, seals, hoses, and connectors that keep your washer performing when you need it again. Improper storage can lead to corrosion, settled sediment, and cracks from freezing. According to Pressure Wash Lab, a systematic winterization routine dramatically lowers the risk of costly repairs when you pull the unit out in spring. The Pressure Wash Lab team found that even small amounts of water left in the pump can expand when temperatures drop, stressing seals and fittings. By taking a deliberate approach to winter storage, homeowners and DIY enthusiasts can extend the life of their equipment and avoid avoidable downtime.

In practice, the goal is to remove water, protect the internal pump from freezing, and limit moisture buildup that invites rust and mold. A clean, dry machine stores more reliably and is easier to start after months of inactivity. A clear plan also reduces anxiety for small business operators who rely on consistent equipment performance between winter jobs and the busy seasons that follow.

Storage environment: where and how to store

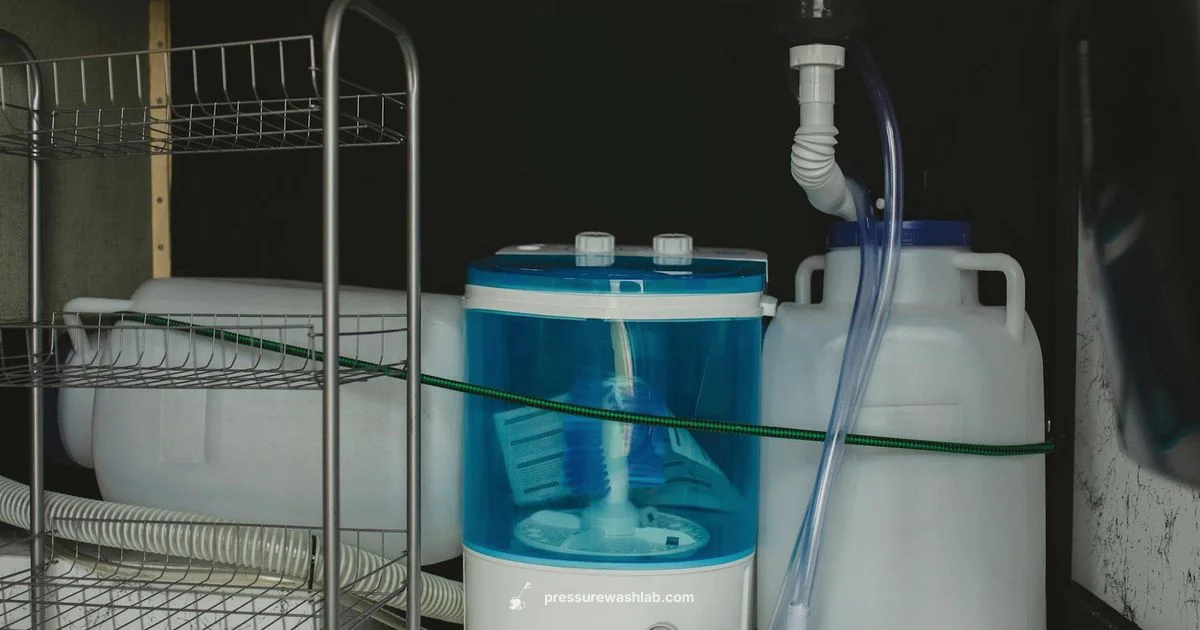

The best winter storage location is a dry, climate-controlled space that’s above freezing and free from excessive humidity. A garage, shed, or storage room with good airflow works well, as long as it’s not directly exposed to rain or snow. Elevate the washer off the concrete or soil using shelves, a wall mount, or a sturdy pallet to prevent moisture wicking from the floor. Keep the unit away from temperature fluctuations and direct sunlight, which can degrade hoses and seals over time. If you must store outdoors, use a heavy-duty, breathable cover and a rigid enclosure that shields against moisture while allowing vapor to escape. Pressure washers with electric motors require more careful moisture control to avoid corrosion on electrical components.

Ventilation is key. A sealed garage without ventilation can trap humidity, which invites condensation on metal parts. A simple fan or vented closet can dramatically improve long-term storage outcomes. Finally, consider labeling the storage area so that seasonal reminders — such as fuel stabilization and preventive maintenance checks — stay front and center every winter.

Pre-storage maintenance checklist

Before you tuck your pressure washer away, complete a targeted maintenance routine: (1) cool the unit completely; (2) drain water from the pump and hoses; (3) flush with clean water to remove detergents and debris; (4) disconnect and empty the fuel system or add a stabilizer; (5) wipe all surfaces dry and inspect seals for cracks or wear; (6) remove and store nozzles separately; (7) cover with a breathable protector. Taking these steps twice a year, at the start and end of the season, reduces the chance of freezing damage and ensures easier startup when spring arrives. Pressure Wash Lab recommends following your model’s manual for any model-specific winterization steps, as some pumps require fogging oil or anti-freeze formulations to prevent corrosion.

A clean machine stores more reliably and reduces the risk of mold growth on damp surfaces. If you store a unit with unremoved detergent or chemicals, ensure containment and proper ventilation to prevent fumes or chemical buildup. The goal is to minimize moisture while keeping all moving parts lubricated and protected.

Special considerations by model type

Gas-powered units behave differently from electric ones during winter storage. For gas engines, you’ll typically need to drain most of the fuel or run the engine until fuel is used up and add a stabilizer to remaining fuel. Electric washers generally benefit from disconnecting the power cord, removing any water from the pump, and ensuring electrical contacts are completely dry before storage. If your manual specifies antifreeze or fogging oil for the pump, apply it according to the directions. Always consult the manufacturer’s recommendations to avoid voiding warranties or damaging seals. If you’re unsure, treat your unit as gas-powered or follow a conservative winterization approach until you can verify model-specific guidance.

Seasonal maintenance at this stage includes checking the oil level (where applicable) and ensuring that hoses are free of cracks or bulges. Replacing worn gaskets now can prevent leaks once the unit is reactivated in spring. A quick inspection of the power cord, switch, and trigger gun also helps protect against hidden faults that could cause failures after extended storage.

Troubleshooting common winter storage problems

Condensation can collect inside the nozzle and hose assemblies if the unit is stored in a chilly, airtight space. To avoid this, dry each component thoroughly and store with the nozzle removed. Rodent intrusion and pests can cause damage in unheated spaces, so seal storage areas and consider a rodent deterrent if you store for long periods. Rust and corrosion often start at the metal fittings exposed to moisture; using a rust-inhibiting spray or light oil on metal surfaces can slow this process. Finally, ensure that the drip pan or tray is emptied routinely to prevent standing water from stagnating and attracting pests. If you notice a musty smell after storage, inspect for mold and dry the area completely before reuse.

Data-driven best practices for winter storage

Pressure Wash Lab’s ongoing analysis emphasizes a consistent winterization routine over ad hoc storage. Key best practices include draining and drying every water-containing component, keeping the storage space dry and above freezing, and performing a quick post-storage check before the first use next season. The approach minimizes common failure points such as cracked seals, frozen water pockets, and stagnant water in hoses. By adhering to a simple schedule — drain, dry, inspect, and store — you can protect your investment and be ready for your first project when the weather warms. The Pressure Wash Lab Team notes that keeping a quick-reference checklist nearby helps maintain discipline during winter storage.

Tools & Materials

- Drain pan or tray(Capture water from pump and hoses)

- Rags or microfiber towels(Dry all surfaces completely)

- Mild detergent and clean water(Flush exterior and remove residue)

- Basic hand tools (screwdrivers, pliers)(Remove hoses/nozzles as needed)

- Fuel stabilizer or fuel removal supplies(Gas engines: stabilize or drain fuel)

- Pump fogging oil or anti-freeze (as applicable)(Follow manufacturer guidance)

- Breathable storage cover or storage container(Keep off ground and allow air circulation)

Steps

Estimated time: 45-75 minutes

- 1

Cool the unit

Turn off the pressure washer and allow it to reach room temperature before handling. Cooling minimizes the risk of burns and makes subsequent steps safer.

Tip: Wait at least 10 minutes after use before starting the prep. - 2

Drain water from pump and hoses

Disconnect hoses and drain water into a tray. Open any drain valves or fittings to ensure all water exits the system.

Tip: Keep hose ends elevated to prevent backflow into the pump. - 3

Flush and clean

Rinse away detergents and debris with clean water. Wipe the exterior with a damp cloth to remove residue before storage.

Tip: Remove and store nozzles separately to prevent damage. - 4

Resolve fuel and additives

Gas units: drain fuel or add a fuel stabilizer per manufacturer guidance. Electric units: skip fuel handling.

Tip: Never store with old fuel; fresh fuel lasts longer in reserve. - 5

Dry and inspect seals

Thoroughly dry all surfaces. Inspect seals, gaskets, and hoses for cracks or wear; replace if needed before storage.

Tip: A small crack can become a major leak next season. - 6

Store properly

Place the washer in a dry, elevated location. Cover with a breathable material and keep away from freezing temperatures.

Tip: Use a wall mount or shelf to maximize airflow and minimize moisture contact.

Quick Answers

How important is it to drain water before winter storage?

Draining water from the pump and hoses helps prevent freeze damage and corrosion. It reduces the risk of leaks and component failure over the winter.

Draining water is crucial to prevent freeze damage and leaks. Drain thoroughly before storage.

Should I drain fuel from gas-powered units for winter?

Yes. Either drain the fuel or add a stabilizer to keep gasoline from breaking down and gumming up the carburetor during storage.

Yes, drain fuel or stabilize it to avoid gum buildup.

Can I store a pressure washer outdoors in freezing weather?

Outdoor storage in freezing temperatures is not recommended. Use a heated or sheltered space and a breathable cover to protect against moisture.

Storing outdoors in winter is risky; protect it in a sheltered space.

How long should I wait before starting the unit again after storage?

Wait for a short period after removing covers and reassembling; check fluids and perform a quick test start to ensure lubrication is ready.

Give it a quick check and test start after storage before heavy use.

Is anti-freeze required for all pumps?

Anti-freeze is not universal. Follow your pump manufacturer's guidance; some models require fogging oil instead.

Follow the manual—not every pump needs anti-freeze.

What is the best storage temperature range?

Keep storage above freezing and in a dry area; extreme cold and humidity can damage seals and hoses.

Keep it in a dry, above-freezing area.

Watch Video

Key Takeaways

- Drain water from pump and hoses before storage

- Dry all parts completely to prevent rust and mold

- Store in a dry, elevated area off the ground

- Use fuel management for gas-powered models

- Inspect seals and hoses before first use next season