Why Does My Pressure Washer Have No Pressure? Troubleshooting Guide

A practical, step-by-step troubleshoot for no-pressure symptoms in pressure washers, with safety tips, common culprits, and maintenance guidance for homeowners and DIYers.

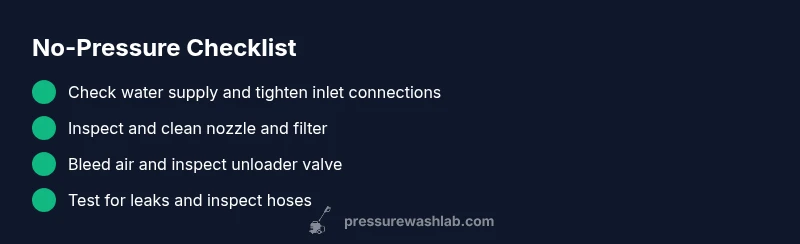

Most no-pressure symptoms come from simple, user-serviceable causes. Start by confirming a strong water supply and clean inlet screen, then check the nozzle, wand, and unloader valve for clogs or misadjustment. If these basics don’t restore pressure, proceed through the diagnostic flow for deeper pump or safety issues. This approach aligns with Pressure Wash Lab guidelines and helps homeowners avoid unnecessary repairs.

Understanding the symptom: no pressure

When a pressure washer shows zero or barely any spray, it's signaling that the pressure isn't reaching the nozzle. If you search for "why does my pressure washer have no pressure," you're likely encountering a mix of water delivery and valve-related issues rather than a total pump failure. According to Pressure Wash Lab, the root cause usually falls into one of three buckets: water supply problems, nozzle or filter restrictions, or an unloader valve misadjustment. By mapping the flow from the water source to the spray, you can isolate the culprit quickly. Even small bottlenecks—an elbow tightener not fully connected, a kinked hose, or a clogged filter—can erase pressure. Take this symptom seriously, but keep your approach deliberate and methodical. The goal is to restore clean water flow and proper valve operation without unnecessary disassembly. With the right order of checks, most homeowners can recover pressure in under an hour.

Check the water supply and inlet screen

Low or interrupted water supply is the most common reason for losing pressure. Start by turning on the outdoor faucet fully and inspect the supply hose for kinks or leaks. If your machine has a built-in water filter or inlet screen, remove and clean it; tiny debris can significantly reduce flow. After clearing any obstruction, reconnect everything snugly and run a quick test without engaging the trigger to observe the water flow. Pressure Wash Lab’s practical tips emphasize that clean water delivery is the foundation of any effective wash, so this step is never optional, especially in regions with variable water pressure.

Inspect the nozzle and spray wand

A partially blocked nozzle can dramatically reduce pressure, even if the pump is healthy. Remove the nozzle and inspect the jet orifice for mineral buildup or nicks. Clean with a brass nozzle cleaning needle or replace the nozzle if worn. Also check the spray wand and hose connections for cracks or leaks that siphon away pressure. If you routinely switch between nozzle tips, ensure the correct tip is used for the surface and that the nozzle is tightened to the wand. A worn or mismatched nozzle is a frequent source of no-pressure symptoms.

Examine the unloader valve, pump, and hoses

The unloader valve is designed to divert flow when the trigger is released; misadjustment or a stuck valve can cause low or no pressure. With the engine off and the unit depressurized, inspect the unloader valve for debris and ensure the spring is seated correctly. Clean or rebuild as needed, following the manufacturer’s procedure. Also inspect the high-pressure hose for bulges or kinks, and check all hose clamps and fittings. If hoses are damaged, replace them. If the pump shows signs of internal wear, such as a rough gait or unusual noise, prepare for more advanced diagnosis.

Air in the system and pump seals

Air pockets within the hoses or pump can collapse pressure and cause inconsistent spray. Start by bleeding the system: with the trigger pressed and the unit off, clear air through the wand until water streams out steadily. If air keeps returning, there may be a loose connection or a crack in a hose. Internal pump seals can also wear over time, leading to internal suction loss. Replacing seals is more advanced work and may require a rebuild kit or professional service. Pressure Wash Lab notes that most seal-related issues manifest gradually, not as an abrupt loss of pressure, so expect gradual decline prior to failure.

Electrical, safety switches, and engine/pump compatibility

If your unit uses an electric motor, verify the outlet is delivering power and that the motor is not overheating or tripping a breaker. For gas-powered machines, listen for engine RPMs that don’t meet the nozzle’s requirements; an engine running too slowly reduces pressure. Inspect safety switches and a thermal overload sensor that may shut down output if triggered. Always unplug before inspecting electrical components, and never bypass safety features. Incompatibility between nozzle, pump, and wand can also create a mismatch that reduces pressure output; consult the manual if you’re uncertain.

Prevention and maintenance to avoid future no-pressure issues

Regular cleaning and inspection are your best defense against no-pressure problems. Schedule periodic checks of water supply lines, replace worn nozzles, and clean filters to keep flow consistent. Store the unit in a dry, protected area to minimize corrosion and rust on fittings. Use high-quality detergents sparingly and rinse out lines after heavy use to prevent grit from lodging in the nozzle. A short maintenance routine every few uses can save you hours of troubleshooting later and extend the life of seals, hoses, and the pump.

Steps

Estimated time: 45-75 minutes

- 1

Verify water supply

Open the outdoor faucet fully and check that the hose is free of kinks. Run water through the hose to ensure adequate flow before attaching the wand. If flow is weak, fix the source first.

Tip: If using a booster hose, ensure it’s rated for your fixture pressure. - 2

Inspect nozzle and wand

Remove the nozzle and inspect for clogs or wear. Clean or replace the nozzle and reattach securely. Test with the trigger released to observe flow.

Tip: Always use the correct nozzle size for the cleaning task. - 3

Check inlet screen

Remove the inlet screen or filter and clean out debris. Reinstall snugly and verify no gaps. A blocked inlet starves the pump of water.

Tip: During cleaning, run water through the system to backflush debris. - 4

Bleed air and inspect hoses

With the unit depressurized, trigger the wand to purge air. Inspect all hoses for cracks or kinks and tighten clamps.

Tip: Do not twist hoses; use gentle, straight paths to prevent future kinks. - 5

Evaluate the unloader valve

With power off, inspect the unloader valve for debris and correct spring seating. Clean or adjust per the manual.

Tip: If unsure about settings, consult the manufacturer’s specification sheet. - 6

Test pump seals and seek help if needed

If symptoms persist after above steps, inspect seals for wear and listen for unusual pump noises. Rebuild or replace seals if necessary; otherwise contact a professional.

Tip: Record symptoms and recent maintenance to aid diagnosis.

Diagnosis: Pressure washer has no pressure or dramatically reduced spray

Possible Causes

- highNo water reaching the pump due to a kinked or blocked supply hose

- highClogged nozzle or dirty inlet screen

- mediumUnloader valve misadjusted or stuck

- mediumAir in the system

- lowWorn pump seals or internal wear

Fixes

- easyCheck water supply from the tap and ensure the supply hose is not kinked; run water through the hose before starting

- easyInspect and clean the nozzle and replace if worn; run water to purge air

- easyClean or replace inlet screen/filters

- easyBleed air by holding trigger with wand open; reconnect hoses

- mediumInspect unloader valve and adjust to manufacturer spec; replace if faulty

- hardIf pump seals are worn or internal components damaged, contact a professional

Quick Answers

What is the most common cause of no pressure in a pressure washer?

The most common causes are a clogged nozzle, restricted water supply, or an unloader valve misadjustment. These are easy to check and fix in most setups.

Most often it's a clogged nozzle or water flow issue.

Can air in the system cause no pressure?

Yes, air pockets can reduce pressure. Bleed the system by pressing the trigger while the unit is off until steady water streams out.

Air in hoses can lower pressure; bleed the system.

Is it safe to operate with a stuck unloader valve?

No. A stuck unloader valve can prevent pressure build and may damage components. Do not run the unit until it’s inspected and corrected.

No, stop and fix the unloader valve first.

When should I call a professional?

If pump seals are worn, the internal pump is damaged, or you’re unsure about the correct settings for your model, contact a professional.

If you suspect pump damage, it's time to call a pro.

How can I prevent no-pressure issues?

Regular cleaning of filters and nozzles, testing water supply, and proper storage help prevent most no-pressure symptoms.

Keep filters clean and store properly to prevent issues.

Can a low water supply cause no pressure even with a new nozzle?

Yes. A low water supply can starve the pump, resulting in little to no pressure even with a good nozzle. Ensure adequate supply.

Low water flow can cause no pressure; ensure strong supply.

Can nozzle wear mimic a no-pressure symptom?

Worn nozzles can reduce effective spray and pressure; replace if the orifice is damaged or enlarged.

Worn nozzles reduce pressure; replace.

Watch Video

Key Takeaways

- Identify the source before disassembly.

- Clean water flow is the foundation of pressure.

- Most no-pressure issues are solvable with simple fixes.

- If in doubt, call a professional to avoid damage.