Why Your Pressure Washer Keeps Cutting Out: A Troubleshooting Guide

Learn why your pressure washer keeps cutting out and follow a practical, step-by-step troubleshooting guide from Pressure Wash Lab to restore reliable performance.

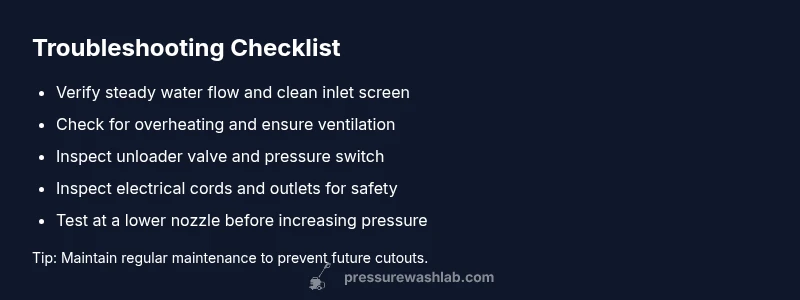

Most likely your pressure washer is cutting out due to water supply issues, overheating, or a faulty unloader valve. Start with the simplest checks: ensure the garden hose is providing steady flow with no kinks, confirm the inlet screen is clean, and verify the water temp isn’t causing thermal shutoff. If the issue persists, inspect the unloader valve and pressure switch for proper operation.

Understanding why a pressure washer keeps cutting out

When a pressure washer suddenly stops spraying and then restarts or refuses to restart, it is typically a safety-centered symptom rather than a mysterious failure. The most common culprits are water supply issues, overheating, or a faulty control valve such as the unloader valve or pressure switch. According to Pressure Wash Lab, homeowners often misinterpret these shutoffs as a dying motor or a random fault, which leads to unnecessary part replacements. This section explains the primary reasons you’re seeing a cutout and how to approach them without risking damage to your unit or personal safety. You’ll learn how to spot symptoms early, differentiate between a water-starved shutdown and an overheated engine, and prioritize fixes that restore reliable operation. Understanding the root causes will help you restore consistent pressure and extend the life of your machine.

Common causes at a glance

A pressure washer that cuts out during use can be caused by several issues, often related to flow, heat, or control hardware. The most frequent culprits are insufficient water supply or clogged inlet screens, overheating or thermal shutoff, a stuck or leaky unloader valve, a faulty pressure switch, and air leaks in the hose or fittings. Less common but possible causes include electrical problems in the outlet or extension cord (for electric models) and fuel issues in gas-powered units. This quick map helps you prioritize checks in order of ease and impact, so you can identify the root cause quickly and avoid replacing parts you don’t need.

Water flow and supply: the first line of defense

Water is the lifeblood of a pressure washer. If the inlet cannot draw enough water, the unit will struggle to maintain pressure and may cut out to protect the pump. Start by ensuring the garden hose delivers steady, unrestricted flow with no kinks, cracks, or leaks. Check the inlet screen on the pump for debris and clean it if necessary. If you have a long hose run or a low water pressure source, consider using a larger-diameter hose or a pump accumulator to maintain adequate flow. Finally, verify that the nozzle you’re using isn’t creating backpressure that starves the pump of water. Small changes here often stop the cutouts without touching the machine’s internals.

Overheating and thermal protection explained

Many units include a thermal cutout that shuts the machine down if they get too hot. Overheating can be caused by high ambient temperatures, continuous operation without breaks, blocked cooling vents, or a clogged nozzle that makes the pump work harder. Allow the engine or motor to cool completely before testing again, and ensure there’s ample ventilation around the machine. If you’re in a hot environment, consider shorter bursts, a lower pressure setting, or moving the unit to a cooler location. Regular cleaning of cooling fins and air paths can dramatically reduce unwanted shutdowns.

Unloader valve and pressure switch: how they control the show

The unloader valve and pressure switch regulate when and how hard the pump builds pressure. If the unloader valve sticks or leaks, or the pressure switch misreads, the system may relieve pressure and cut out prematurely. Clean or replace a stuck unloader valve and ensure it’s calibrated to the correct pressure range for your nozzle. A faulty switch can also mimic a cutout; test continuity with a multimeter or replace the switch if you detect erratic readings. In many cases, re-seating connections and ensuring hoses are free of leaks resolves the problem.

Electrical or fuel issues (electric vs gas models)

Electric pressure washers rely on a stable outlet and a grounded cord. Check for damaged cords, tripped GFCI outlets, or circuit breakers that may interrupt power during operation. For gas-powered units, fuel mixture, spark plug or carburetor settings, and air filter cleanliness affect running stability. A lean fuel mix or dirty air filter can cause surges that trigger safety cutouts. Always disconnect power or spark plug wire before inspecting electrical components, and follow the manufacturer’s service manual for fuel-related adjustments.

Quick checks you can perform right now

- Ensure the water source provides continuous flow and the inlet screen is clean.

- Inspect hoses for kinks and leaks; replace damaged sections.

- Let the unit rest if it feels extremely hot; never run a hot machine continuously.

- Check the unloader valve and pressure switch for proper operation.

- Confirm the nozzle size matches your intended task and does not create excessive backpressure.

- Verify the power plug, cord, and outlet are safe and dry before powering on.

These checks are low risk and often resolve cutouts without disassembly. If you still see shutdowns after these steps, move to the diagnostic flow below.

A practical diagnostic flow you can follow

Symptom: The washer cuts out during spraying Causes and fixes:

- high: Low water supply or restricted inlet flow — fixes: clean filter, ensure flow

- high: Overheating — fixes: cooldown, ventilation

- medium: Unloader valve fault — fix: clean/replace

- medium: Pressure switch fault — fix: test/replace

If none of these resolve the issue, check electrical components and seek professional help. Always stop if you smell gas, hear hissing, or notice water leaking from unsafe spots.

Maintenance and prevention to avoid future cutouts

Regular maintenance is essential to prevent future interruptions. Create a simple service schedule that includes cleaning the inlet screen every few uses, inspecting hoses for wear or leaks, and keeping vents clear. Use clean, cool water, and avoid running the unit in direct sunlight or enclosed spaces where heat can accumulate. Replace worn parts on a reasonable timeline and use only manufacturer-recommended accessories and fluids. Finally, store the unit in a dry, sheltered place and perform a quick test after long storage to catch any latent issues before the next project.

Steps

Estimated time: 60-90 minutes

- 1

Power off and secure safety

Disconnect from power, close water source, and relieve any built-up pressure by squeezing the spray gun trigger. For gas units, shut off fuel and allow the engine to cool before inspection.

Tip: Always remove the spark plug boot on gas models before handling hot components. - 2

Check water source and flow

Inspect the garden hose for kinks or leaks and ensure a steady flow into the inlet. If you have low supply, shorten hoses or boost flow with a larger-diameter hose.

Tip: Run the water without the wand to verify continuous flow first. - 3

Inspect inlet filter/screen

Remove the inlet screen from the pump and clean any debris. Reinstall securely and re-check flow before testing.

Tip: Use a soft brush and avoid abrasive cleaners that could scratch the screen. - 4

Test for overheating and venting

Let the unit sit and cool completely. Check for blocked cooling vents and clear away dust build-up that impedes airflow.

Tip: On hot days or enclosed spaces, perform shorter bursts to reduce heat buildup. - 5

Inspect unloader valve

Locate the unloader valve; clean if dirty and ensure it moves freely. If needed, replace with a compatible part.

Tip: Document the exact model and part number before replacement. - 6

Check pressure switch and wiring

Test the switch with a multimeter for proper continuity. Re-seat or replace faulty connections.

Tip: Always unplug the unit before performing electrical tests. - 7

Reassemble and test at low pressure

Reassemble components, re-connect water and power, and run at a low nozzle setting to observe stability.

Tip: Gradually increase pressure while watching for any cutouts. - 8

Inspect electrical outlets/cords

Check for damaged cords, plug integrity, and that the outlet isn’t on a shared circuit with high-demand devices.

Tip: Use a heavy-duty extension cord appropriate for outdoor use if needed. - 9

Decision point for parts or pro help

If symptoms persist after these steps, determine whether parts replacement is warranted or if a professional service is required.

Tip: Keep a symptom log to aid the technician if you hire one.

Diagnosis: Pressure washer cuts out intermittently during use

Possible Causes

- highLow water supply or restricted inlet flow

- highOverheating or thermal shutoff

- mediumUnloader valve fault

- mediumPressure switch fault

- lowElectrical issues (outlet/cord) or fuel issues (gas models)

Fixes

- easyCheck water source and inlet screen; ensure steady flow and clean filter

- easyLet unit cool, improve ventilation, and verify nozzle creates no excessive backpressure

- mediumInspect and clean/unload valve; recalibrate or replace if stuck/leaking

- mediumTest/replace pressure switch; verify wiring connections

- mediumCheck electrical outlets, cords, and fuel system (gas models); replace damaged components

Quick Answers

Why does my pressure washer cut out after a few seconds?

Most cutouts are due to water flow problems, overheating, or a faulty control valve. Start by checking water supply and inlet screen, then inspect cooling and unloader valve. If the symptom persists, move to electrical checks.

Common causes are water flow problems, overheating, and valve issues. Begin with the water supply and inlet, then check cooling and valve components.

How can I tell if the unloader valve is faulty?

A stuck or leaking unloader valve often causes the unit to release pressure and shut down. Clean the valve, verify movement, and replace if necessary after testing. A review of accompanying pressure switch behavior helps confirm the fault.

If the unit relieves pressure or stops while still spraying, the unloader valve may be faulty. Clean or replace as needed.

Is overheating a safety feature?

Yes. Thermal protection shuts the machine down to prevent damage when temperatures get too high. Allow it to cool, improve ventilation, and adjust usage to prevent heat buildup.

Yes, most units have a thermal cutout. Cool down and improve airflow before trying again.

Do I need to replace the pump if it keeps cutting out?

Not always. In many cases the issue is related to water flow, cooling, or valve components. Only replace the pump after confirming other causes or as advised by a professional.

Usually you don’t need to replace the pump right away. Check other components first.

Can a dirty inlet filter cause cutouts?

Yes. Debris in the inlet filter restricts flow and can trigger shutdowns. Clean or replace the filter and re-test.

A clogged inlet filter can trigger shutoffs; clean or replace it and test again.

Watch Video

Key Takeaways

- Identify root causes before replacing parts

- Start with water flow and cooling checks

- Unloader valve and pressure switch are common culprits

- Use a structured diagnostic flow for consistent results

- When in doubt, seek professional help