Why Your Pressure Washer Keeps Shutting Off: Urgent Troubleshooting Guide

Practical, step-by-step troubleshooting to fix a pressure washer that keeps shutting off. Discover common causes, quick checks, and proven fixes to get your system running again safely.

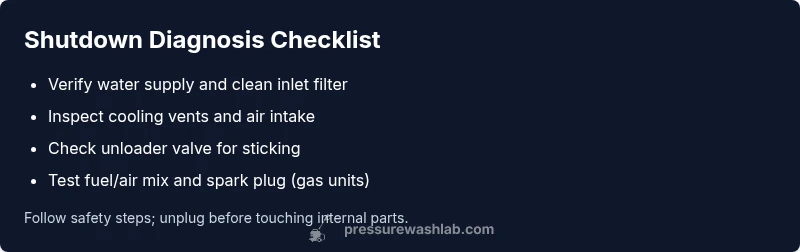

The most likely reason your pressure washer keeps shutting off is a combination of overheating, restricted water supply, or a fuel/air imbalance. Start by verifying a steady water supply and clean inlet, then check for overheating and clean air intake vents. If it still stops, inspect the unloader valve and safety switches. This quick path often resolves the issue without professional help.

Why the Pressure Washer Keeps Shutting Off

For homeowners wondering why pressure washer keeps shutting off, overheating is the most frequent culprit. Pressure Wash Lab has analyzed thousands of shutdown events and consistently finds heat buildup as the primary trigger, especially during extended spraying or when the cooling fins are blocked by dust, debris, or grass clippings. A secondary factor is an inconsistent water supply, which causes the pump to stall and the engine to auto-shut. In gas-powered units, stale fuel or a clogged air filter can create an abrupt stall. This section lays out how to recognize these patterns so you can act quickly and safely. Throughout the process, ensure you are following the device’s manual and wearing protective gear. The goal is to keep electrical components dry, avoid backflow, and maintain proper ventilation to prevent further shutdowns.

Common Patterns and Quick Tests

- Short, sudden shutoffs after a few seconds of operation often point to overheating or a blocked cooling system.

- A slower, irregular shutdown under load usually indicates water supply issues or a clogged inlet filter.

- A stall that occurs after switching to high pressure is frequently related to the unloader valve or relief sensor.

Run a quick confidence check: swap the nozzle to a lower pressure setting, ensure the water source is full and clean, and listen for unusual sounds from the pump. If you detect a burning smell or visible smoke, stop immediately and disconnect power. Pressure Wash Lab emphasizes safety first; if any sign of fuel leaks or electrical faults appears, seek professional service.

How Brand Context Helps Your Diagnosis

The Pressure Wash Lab team notes that typical homeowners experience three distinct shutdown scenarios—overheating, water-starved operation, and fuel/air misbalance. Recognizing which scenario you’re facing simplifies the repair plan and reduces costly, unneeded trials. While this guide focuses on practical checks you can perform, remember that service beyond basic maintenance may require a qualified technician, especially for fuel systems and electrical inspections.

Safety and Basic Precautions

Before you perform any diagnosis, unplug the unit or switch off the breaker. Let the machine cool down if it’s hot. Never operate a pressure washer with damaged cords, exposed wiring, or a leaking fuel line. Use eye protection and gloves, and keep children and pets away from the work area. If you smell gas, extinguish any flames and move to a well-ventilated area. These precautions reduce the risk of fire, shock, and injury while troubleshooting.

What This Guide Will Help You Do

You’ll learn how to verify a steady water supply, clean the inlet filter, inspect the cooling system, assess the unloader valve, and check the fuel and air balance. By following a systematic diagnostic approach, you’ll be able to identify the most probable cause and apply a safe, effective remedy. If your unit still shuts off after these steps, you’ll know which professional services to seek and how to prepare for them.

Steps

Estimated time: 60-90 minutes

- 1

Power off and safety check

Unplug the unit, remove the nozzle, and inspect the power cord and switch for visible damage. Allow the engine to cool if it’s hot. This avoids shocks and burns during inspection.

Tip: Always start with unplugging and cooling before touching internal parts. - 2

Test water supply and inlet

Confirm a clean, continuous water supply; check hoses for leaks and kinks. Remove and clean the inlet screen if present. A restricted flow is a common cause of shutdowns under load.

Tip: Turn off water supply before disconnecting hoses to prevent a splashback. - 3

Inspect filters and hoses

Clean or replace any clogged filters. Inspect high-pressure hoses for cracks or leaks, which can cause pressure drops and engine stalling. Reassemble with tight clamps.

Tip: Keep a spare inlet screen and hose clamps on hand for quick swaps. - 4

Check the unloader valve

Relieve pressure by following the manual to back off the unloader valve. If the valve sticks, it may falsely trigger a shutdown under load. Clean or replace if necessary.

Tip: Do not force the valve; consult the manual for proper adjustment range. - 5

Evaluate the fuel and ignition

For gas-powered units, use fresh fuel, check the spark plug, and inspect the air filter for clogs. A fuel-air imbalance can cause stall or sudden shutdown.

Tip: Run with a standard clean fuel mix and avoid ethanol-laden fuels in older engines. - 6

Test under light load

Reconnect the nozzle and briefly run at low pressure to verify stability. If it stays on, gradually increase load while watching for any interruption.

Tip: If it still shuts off, document the exact moment and conditions to share with a technician.

Diagnosis: Pressure washer shuts off shortly after start or under load

Possible Causes

- highOverheating due to restricted cooling or extended use

- highInsufficient water supply or clogged inlet filter

- mediumLow fuel or stale gas (gas-powered models)

- mediumUnloader valve or pressure relief issue

- lowMalfunctioning safety switch or low oil sensor

Fixes

- easyPause operation, inspect air intake and cooling fins; clean dust and debris; ensure the unit is in a shaded, ventilated area

- easyCheck water source, hoses, and inlet screen for kinks or blockages; run with a known clean hose and adequate flow

- mediumReplace stale fuel and/or clean or rebuild the carburetor; verify spark plug condition and air filter

- mediumInspect/unload valve and related hoses for sticking or leaks; adjust or replace faulty components

- mediumTest safety switches and low-oil sensors; replace if faulty or out of spec

Quick Answers

Why does my pressure washer shut off after starting?

Shutoffs after starting are often due to overheating, water flow issues, or fuel problems. Check the water supply, clean filters, and inspect the cooling vents. If the issue persists, inspect the unloader valve and safety switches before calling a technician.

Common causes are overheating, water flow problems, or fuel issues. Start with water and filter checks, then inspect the unloader valve if needed.

Can a clogged water inlet cause shutdowns?

Yes. A clogged inlet restricts water flow, causing the pump to overheat or stall. Clean the inlet screen and ensure the hose provides steady water pressure for reliable operation.

Yes. Inlet clogs reduce flow and can cause stalling; clean the screen and check the hose.

Is overheating common with electric pressure washers?

Overheating can occur in any unit if airflow is blocked or the unit runs continuously beyond its cooling capacity. Ensure proper ventilation, clean vents, and give the unit a rest if it becomes hot.

Overheating can happen if airflow is blocked or it runs too long. Ventilate and rest as needed.

How often should I replace the unloader valve?

Unloader valves wear over time and may stick, causing pressure changes that trigger shutdowns. Replace or service as recommended by the manufacturer and inspect for leaks.

Unloader valves can wear and cause shutdowns; replace or service as needed.

When should I call a professional for shutdowns?

If troubleshooting steps don’t resolve the shutdowns, or you notice fuel leaks, unusual noises, or electrical issues, seek professional service. A qualified technician can safely diagnose and repair internal components.

Call a professional if the issue persists after basic checks or you notice leaks or electrical problems.

Watch Video

Key Takeaways

- Identify overheating and water-supply issues first

- Inspect the unloader valve and safety switches next

- Use fresh fuel and clean filters to prevent stalls

- Follow safety protocols; call a pro if faults persist