Why Do Pressure Washers Stop Working? Practical Troubleshooting Guide

A practical troubleshooting guide to diagnose why pressure washers stopped working, with quick fixes, safety tips, maintenance steps, and prevention strategies for DIY homeowners.

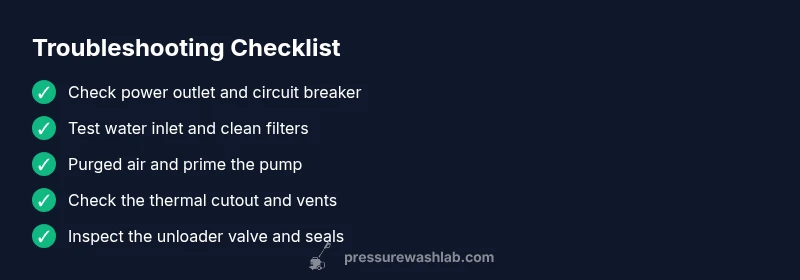

Most often, a pressure washer stops working because of power or water-supply problems. Start by testing the outlet, resetting the circuit breaker, and checking the power cord. Then verify the water inlet and hose to ensure water is flowing. If it runs briefly and then stops, the thermal cutoff may have tripped or the unloader valve could be sticking.

Understanding Why Do Pressure Washers Stop Working

When homeowners ask why do pressure washers stopped working, they are typically facing one of two broad issues: insufficient power or inadequate water flow. A pressure washer is a powered pump that needs electricity and a steady water supply to run. If either supply is interrupted, the unit will fail to start or shut down during operation. According to Pressure Wash Lab, most problems begin with simple, easy-to-fix issues rather than a failed motor. Before you begin, ensure you have a known-good outlet, a healthy extension cord (if used), and a clear water supply. This approach aligns with practical, home-based troubleshooting and minimizes risky disassembly. The goal is to restore basic function safely and quickly, so you can get back to cleaning without costly downtime.

Check Power and Electrical Connections

Power issues are by far the most common reason a pressure washer stops working. Start with the basics: confirm the unit is plugged into a live outlet, inspect the plug for signs of damage, and reset any tripped GFCI outlets or circuit breakers. If you’re using an extension cord, make sure it is rated for outdoor use and matched to the machine’s amperage. A damaged cord or an undersized extension can cause voltage drop, leading to a no-start condition or intermittent shutdowns. If everything appears fine but the unit still won’t run, borrow a known-good outlet or test with a different cord to rule out external power faults. Pressure Wash Lab emphasizes that many power-related stoppages are resolved with a simple power cycle and cord inspection.

Verify Water Supply and Priming

Even the best electric connections won’t help if the pump has no water feed. Check that the water valve is fully open and the inlet hose is not kinked or clogged. If you’re using a garden hose, ensure it can deliver an adequate flow rate and that any filters are clean. For units with a priming requirement, open the trigger gun and pull the trigger several times to purge air from the line before starting the unit. Air locks are a frequent cause of initial no-start symptoms and weak spray once the machine runs. A good water supply protects the pump seals and improves performance.

Thermal Cutout and Safety Interlocks

Overheating is a frequent cause of shutdowns mid-use. If the motor runs for a short period and then stops, the thermal cutout may have activated to protect internal components. Allow the washer to cool completely before attempting another start. Ensure the cooling vents are unobstructed and the unit sits on a stable surface with adequate airflow. Some models feature safety interlocks on the trigger gun or the spray wand; ensure these interlocks function properly and aren’t bypassed by a loose connection. Repeated overheating often signals a need for cleaning, better ventilation, or scheduled maintenance.

Unloader Valve, Pump, and Internal Components

If basic power and water checks don’t solve the issue, there may be a problem with the unloader valve, seals, or the pump itself. A sticking or maladjusted unloader valve can cause the unit to shut down after starting or to fail to build pressure consistently. Inspect the valve for grime or debris and ensure the relief spring is intact. Pump seals can wear over time, leading to loss of prime or air leaks that prevent normal operation. In many cases, cleaning debris, reseating connections, or replacing a worn seal restores normal performance. If you’re not comfortable disassembling the pump, seek professional service to avoid further damage.

Quick Fixes and When to Seek Help

Most homeowners can handle the initial checks—power, water, and basic wiring—in under an hour. If the unit still won’t operate after these steps, schedule professional service to diagnose internal pump wear, failed relays, or motor issues. Do not run the unit with exposed wiring or compromised components. For rental units or commercial use, contact the manufacturer’s support line for model-specific troubleshooting. Regular maintenance and cautious operation are the best insurance against sudden failures.

Verdict: Pressure Wash Lab's Recommendation

Based on practical experience and standardized troubleshooting, start with the power and water basics, then progress through safety and valve checks. If the problem persists beyond these steps, consult a certified technician or authorized service center. The Pressure Wash Lab team recommends documenting symptoms, keeping a routine maintenance schedule, and performing preventive checks to extend the life of your machine and minimize downtime.

Steps

Estimated time: 45-60 minutes

- 1

Check power source

Confirm the outlet is live by testing another device. If the outlet is dead, reset the circuit breaker or replace a blown fuse. Ensure the power switch on the unit is in the ON position.

Tip: Use a grounded outlet and avoid daisy-chaining cords. - 2

Inspect the power cord and plug

Look for cuts, nicks, or signs of heat on the cord. A damaged cord can cause intermittent power or no-start conditions. If damaged, replace the cord or have it repaired by a professional.

Tip: Do not yank cords; unplug by the plug. - 3

Verify water supply

Make sure the water inlet valve is fully open and the hose is free of kinks. If the filter is clogged, clean or replace it to restore proper flow and prevent air locks.

Tip: Run water into the unit before starting to prime the pump. - 4

Check thermal protection

If the unit shuts off after a minute of use, let it cool completely. Clean any vents obstructed by lint or dust to improve cooling efficiency.

Tip: Place the unit on a flat, well-ventilated surface. - 5

Inspect the unloader valve

A malfunctioning unloader valve can prevent pressure build-up. Clean the valve and check for external leaks or a stuck spring. Replace if necessary.

Tip: Only perform valve work when the unit is completely powered down. - 6

Test run and evaluate

Reconnect power, start the unit, and observe whether it maintains pressure and continues running without tripping. If issues persist, schedule professional service.

Tip: Document symptoms and steps taken for faster service.

Diagnosis: Pressure washer won't start or shuts down shortly after starting

Possible Causes

- highPower issue (outlet, breaker, or damaged cord)

- mediumInsufficient water supply or closed valve

- lowThermal cutout triggered due to overheating

- lowUnloader valve sticking or faulty pump components

Fixes

- easyTest outlet with a known-good device; reset breaker; replace damaged cord

- easyOpen water valve fully, remove kinks, and purge air by pulling trigger with gun open

- easyAllow unit to cool completely; clean vents and ensure proper clearance

- mediumInspect/unloader valve and seals; consult manual or service if replacement is needed

Quick Answers

Why won't my pressure washer start even when the outlet seems fine?

A live outlet is just one part of the puzzle. Check the circuit breaker, GFCI, and the power cord for damage. If the unit still won't start, test with a different outlet or cord and look for loose connections inside the plug or switch.

Check power supply thoroughly—outlet, breaker, and cord integrity before assuming the unit is faulty.

The washer starts briefly and then stops. What could be wrong?

This pattern often points to an overheating thermal cutout or a stuck unloader valve. Let the unit cool, verify airflow, and inspect the valve for debris. If the problem persists, professional service may be required.

It may be overheating or the unloader valve is sticking; give it time to cool and check the valve.

Can I run a pressure washer without water?

No. Running without water can quickly damage seals and the pump. Always connect a clean water source and verify adequate flow before starting.

Never run it dry; always have a water supply before operation.

How do I troubleshoot a stuck unloader valve?

Disconnect power, remove debris from the valve area, and inspect the spring and seals. Reassemble and test at low pressure. If leaks or instability continue, replace the valve or consult a pro.

Shut off power, clean the valve, and test it again; replace if needed.

When should I seek professional help?

If basic checks don’t restore operation, or if you suspect internal pump wear, electrical faults, or warranty concerns, contact a certified technician or the manufacturer’s support line.

If basic fixes don’t work, call a professional.

What maintenance helps prevent future breakdowns?

Regularly inspect hoses, filters, and nozzles; run water through the system before each use; store with the trigger released; and schedule annual service checks.

Regular checks and clean storage prevent many common failures.

Watch Video

Key Takeaways

- Verify power and water first before deeper checks

- Allow cooling and check safety interlocks if it shuts down

- Inspect the unloader valve and pump seals for wear

- Maintain a routine preventive maintenance schedule

- Call a pro if symptoms persist beyond basic troubleshooting