Why Is My Pressure Washer Not Powerful? Troubleshooting Guide

Struggling with a weak pressure washer? This urgent troubleshooting guide explains why is my pressure washer not powerful and how to fix it fast with practical checks, nozzle care, and pump health.

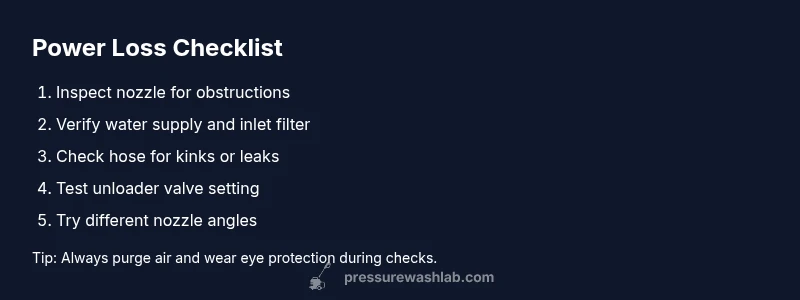

Most power loss with a pressure washer comes from simple, fixable culprits. If your spray is weak, start with the nozzle, water supply, and unloader valve. Quick fixes: clean or replace the nozzle, verify a steady water flow, and check the unloader valve setting for correct pressure. If the issue persists, move through the diagnostic flow or consult a professional.

Understanding the Power Gap: Why your pressure washer feels weak

When homeowners ask why is my pressure washer not powerful, the answer is often a combination of simple, correctable factors rather than a failed motor. The most common culprits are a clogged nozzle, an inadequate water supply, or a misadjusted unloader valve. Pressure washers rely on a constant flow of clean water to create high-velocity jets; any bottleneck in flow reduces effective pressure at the surface. According to Pressure Wash Lab, many power-loss cases originate in the fluid path and nozzle selection rather than the motor itself. Start by verifying you have a steady water supply and a clean inlet screen. If the inlet is starved or partially blocked, the pump cannot develop full pressure, and the spray will feel anemic. The nozzle matters too: using the wrong tip or a worn nozzle can dramatically reduce impact, even if the motor runs smoothly. Finally, inspect the unloader valve—if it sticks open or is set too low, pressure bleeds back into the system. Address these areas first, and you’ll likely reclaim most of your lost performance. This is precisely why is my pressure washer not powerful questions often begin with simple checks rather than expensive repairs.

Quick checks you can perform before diving deeper

If you’re asking why is my pressure washer not powerful, start with a rapid, methodical audit. First, ensure your water supply is open and unobstructed, and that you’re not fighting a kinked or stretched hose. Next, inspect the nozzle and wand for blockages; even a small blockage can dramatically cut flow. Third, check the inlet screen or filter—debris here can choke the pump. Fourth, confirm you’re using a nozzle appropriate for the job; worn or damaged tips reduce efficiency. Finally, test the unloader valve setting; an incorrect setting can divert pressure away from the nozzle. If you’ve completed these checks and still experience reduced power, you’re ready to move into deeper diagnostics. Pressure Wash Lab notes that most losses are tied to fluid path issues rather than a failed motor. If you need a quick, permanent fix it’s often a matter of replacing the worn nozzle or cleaning the intake.

Steps

Estimated time: 20-45 minutes

- 1

Verify water supply and inlet condition

Turn on the water supply and run water through the system before engaging the wand. Check the inlet screen for debris and clean if necessary. A clean, steady flow is essential for restoring power to the spray.

Tip: Let the system purge for a few seconds to clear any trapped air. - 2

Inspect and clean the nozzle/wand

Detach the nozzle and inspect for tip wear or blockages. Clean with a soft brush and reattach, using the correct nozzle for your task. A worn or clogged nozzle can dramatically reduce performance.

Tip: Compare with a known-good nozzle to confirm performance. - 3

Check the inlet filter and hose integrity

Remove and clean the inlet filter; replace if frayed or damaged. Inspect the hose for kinks, leaks, or collapsed areas that restrict flow. Reconnect and test the spray.

Tip: Never run the unit with a damaged hose; it can blow out or cause leaks. - 4

Test nozzle variety and spray pattern

Try a different nozzle size and angle to observe changes in spray power. Some surfaces require wider spray while others benefit from a narrow jet. Record which configuration yields best results.

Tip: Start with the widest spray for safety and gradually narrow if needed. - 5

Assess the unloader valve setting

Verify that the unloader valve is properly configured for your engine speed and pressure needs. A valve stuck open or misadjusted can bleed pressure back into the system, reducing nozzle output.

Tip: If in doubt, reset to the manufacturer’s recommended setting. - 6

Perform a pump health check or seek pro help

If the spray remains weak after the previous steps, you may have internal wear or seals needing attention. A professional service visit can diagnose pump wear, seals, or internal component faults.

Tip: Document symptoms and steps taken to speed up diagnosis.

Diagnosis: Weak spray or insufficient power from the pressure washer

Possible Causes

- highClogged nozzle or spray tip

- highInadequate water supply or low intake flow

- mediumDirty inlet filter or kinked/blocked hose

- lowWorn or misadjusted unloader valve or damaged pump seals

Fixes

- easyClean or replace nozzle and spray tips; verify compatibility with the model

- easyTest water supply and straighten/replace the inlet hose; ensure adequate flow

- easyClean or replace the inlet filter; remove kinks and replace damaged hoses

- mediumInspect and adjust the unloader valve; replace worn seals or consult a service professional if internal wear is suspected

Quick Answers

What is the most common reason a pressure washer loses power?

The most common causes are a clogged nozzle or an inadequate water supply. Debris in the inlet filter or a misadjusted unloader valve can also hamper performance.

Usually it's a clogged nozzle or a weak water supply, sometimes the unloader valve is misadjusted.

Can a faulty unloader valve cause low pressure?

Yes. A stuck or misadjusted unloader valve can divert pressure away from the nozzle, resulting in weak spray. Check and adjust or replace if needed.

Yes, an unloader valve issue can cause low pressure.

Will a clogged inlet filter reduce power?

A dirty inlet filter can restrict water flow, reducing pressure. Clean or replace the filter to restore proper flow.

A clogged inlet filter can lower power; clean or replace it.

Is the pump the likely culprit for ongoing low power?

Pump wear or internal seals can cause gradual power loss. If exterior checks fail, a professional pump assessment is recommended.

It could be pump wear; consider a professional check if other fixes don’t help.

Should I use a smaller nozzle to boost power?

A smaller nozzle increases PSI but reduces overall flow. Use the nozzle range recommended by the manufacturer for your task.

Smaller nozzles can raise pressure but lower flow; follow manufacturer guidance.

When should I call a professional?

If you suspect internal pump wear, damaged seals, or unloader valve problems, a professional service is the safest option.

Call a pro if you suspect pump or valve wear.

Watch Video

Key Takeaways

- Start with simple checks before disassembly

- Clean or replace the nozzle and confirm water flow

- Check the unloader valve and filters first

- If issues persist, consult a pro for pump wear diagnosis