Can You Make a Pressure Washer with an Air Compressor? Feasibility and Alternatives

Explore whether an air compressor can power a pressure washer, the science behind it, safety concerns, and practical alternatives for homeowners and DIYers.

Can you make a pressure washer with an air compressor? In short, not as a drop-in replacement for a traditional water-driven machine. A standard air compressor cannot pressurize water directly; pressure washers rely on a dedicated water pump. Without a proper pump, water management becomes unsafe and inefficient. For cleaning tasks, use a purpose-built pressure washer or a pneumatic water-pump system designed for liquids.

Why this concept is challenging

Can you make a pressure washer with an air compressor? This question often surfaces during equipment planning, but the underlying physics tell a clear story. A traditional pressure washer relies on pressurizing water and delivering a high-velocity water stream through a nozzle. An air compressor, by contrast, pressurizes gases, not liquids, and cannot reliably push water through a pump at the volumes required for effective cleaning. Without a pump that can handle liquids, compressed air simply can't create the sustained water flow needed to lift grime from concrete, siding, or vehicles. Water must be drawn from a reservoir, moved through a pump, and delivered through a nozzle with controlled flow. Without a pump, you’ll also face cavitation and hose-failure risks that can cause leaks or dangerous sprays. For most cleaning tasks, a purpose-built water pump powered by electricity or gasoline is the reliable choice. The feasibility debate hinges on integrating a liquid pump with the air source, not on air pressure alone.

From a design perspective, the water side is where the real work happens. Air pressure can assist tools or dry surfaces, but it cannot substitute the hydraulic power that pushes water through a nozzle at consistent pressure and volume. This is why most DIY attempts end up needing a conventional washer anyway, or a purpose-built pneumatic liquid pump designed for controlled water flow.

How a pressure washer actually works

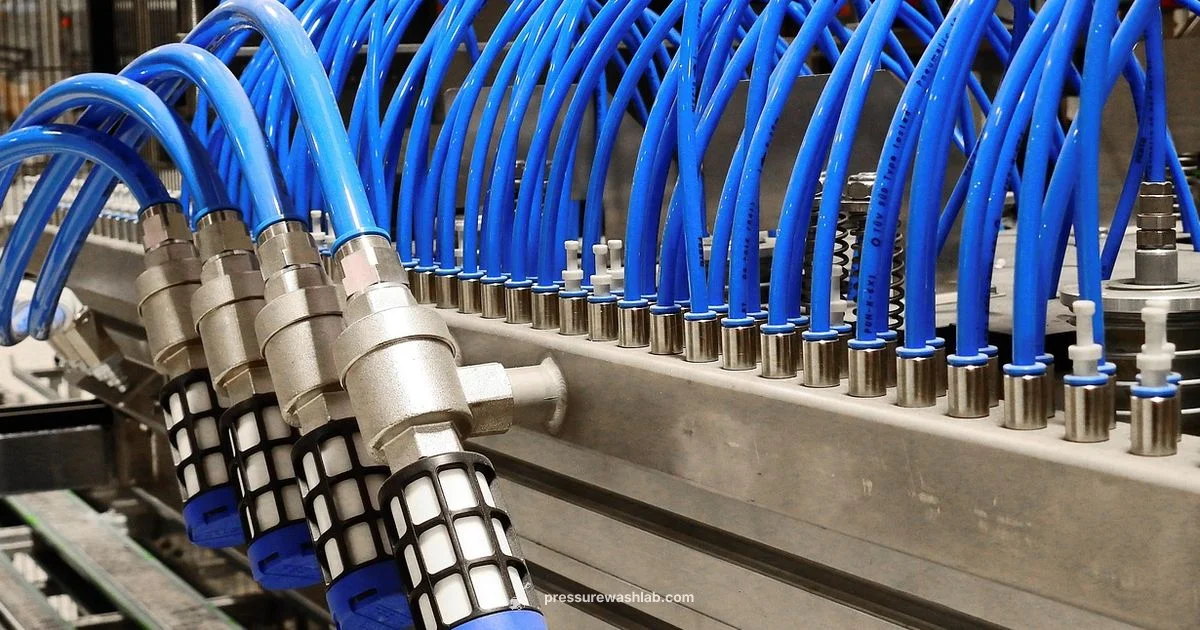

A pressure washer takes clean water from a source and increases its pressure with a pump. The high-pressure water is then directed through hoses to a nozzle, where the spray pattern and flow are controlled. In consumer models, you’ll typically find a choice of pump types (for example, triplex plunger pumps or wobble/diaphragm variants) driven by an electric motor or an internal combustion engine. The machine’s performance is described by two key specifications: PSI (pounds per square inch) and GPM (gallons per minute). PSI tells you how hard the water is pushed; GPM tells you how much water is delivered per minute. Nozzles with different orifices alter the spray shape, from a wide fan to a narrow, high-velocity jet. The water path—source, pump, hoses, and nozzle—defines reliability and effectiveness. Knowing these basics helps you compare models and match them to your cleaning jobs. Any consideration of air-driven alternatives should start by understanding how the water side actually works and why it’s difficult to replace with air.

Can you power one with an air compressor?

In theory, you could attempt to use an air compressor to drive a water pump, or to operate a diaphragm pump that moves water with compressed air. Some specialized, commercial systems do use air to drive a liquid pump, but this approach adds significant complexity and cost. The typical hobby or home workshop air compressor offers limited airflow (CFM) and pressure consistency, which makes it hard to sustain the water pressure a typical washer requires for effective cleaning. Energy conversion losses from air to water further reduce efficiency, so even if you could make a setup work, you’d likely end up with slower cleaning and greater wear on components. In addition, moisture and oil in the air lines can contaminate seals and degrade performance. If you’re curious about this route, research dedicated pneumatic liquid pumps built for liquids and follow manufacturer guidance. For most users, the risks, noise, maintenance needs, and reduced reliability outweigh any potential benefit. The safer path is to rely on a real water pump powered by electricity or gasoline, paired with a proper water source and nozzle.

If you still want to explore it, treat this as a learning experiment rather than a recommended solution for home cleaning. Start with understanding the air-to-water transfer mechanism and only work with documented, purpose-built equipment designed for liquids.

Practical alternatives that achieve similar results

If your goal is efficient cleaning, there are safer and more practical routes than trying to replace the water pump with air pressure. Consider these alternatives:

- Use a purpose-built electric or gas-powered pressure washer appropriate for the job. These machines are designed to handle water flow, pump duty cycles, and nozzle options with built-in safety features.

- Use a water spray system that combines a bucket or reservoir with an air-assisted spray gun intended for liquids. While this still uses water pressure, it is designed specifically for controlled cleaning and chemical delivery.

- Employ a water-fed sprayer that uses a separate pump to deliver water at the required pressure, and pair it with a controllable spray wand. This approach keeps air separate from the water path and reduces risk.

- For light-duty tasks, a high-pressure garden hose with a quality nozzle and detergents can be an affordable option, though it won’t match a real pressure washer’s performance.

In short, the most reliable and safe route is to select a properly rated pressure washer for your tasks, or to use a dedicated pneumatic liquid pump system if you have a clearly documented use case and manufacturer support.

Safety considerations and best practices

Safety must come first when dealing with high-pressure cleaning. High-velocity water jets can cause serious injuries and even damage surfaces if misused. Electricity and water are a dangerous combination—never operate electric equipment near water without proper grounding and GFCI protection. If you’re experimenting with any air-to-water approach, maintain clear separation between the air supply and the water path, use appropriate fittings rated for liquids, and wear protective gear (eye protection, gloves, and sturdy footwear). Do not modify equipment beyond manufacturer guidance, and avoid creating improvised adapters or high-pressure hoses that lack pressure rating tests. Always follow local regulations and the manufacturer’s safety instructions. When in doubt, prioritize buying a certified pressure washer rather than attempting a DIY hybrid that could fail catastrophically.

How to choose a pressure washer instead

Choosing the right pressure washer starts with your tasks. For light patio cleaning, you’ll want a model with moderate PSI and GPM, a reliable electric motor, and a compact form factor. For heavy-duty jobs like concrete or large outdoor surfaces, seek higher PSI, robust build quality, and a durable pump. Consider features such as automatic shutdown, thermal protection, chemical dilution options, and easy-access service points. Don’t forget nozzle types and spray patterns, detergent compatibility, hose length, and overall weight. Read reviews that focus on real-world performance, and verify warranty terms. In most cases, investing in a purpose-built pressure washer will deliver safer operation, predictable results, and lower long-term costs than attempting to retrofit an air compressor into a water pump.

Bonus: what to buy instead (quick-start guidance)

- For general household use, a portable electric pressure washer in the mid-range PSI and GPM is typically sufficient.

- For stubborn outdoor stains, a gas-powered washer with higher endurance is often better suited than a DIY air-based system.

- If you require spray precision and chemical application, look for models with adjustable nozzle kits and compatibility with detergents. Always prioritize safety features, reputable brands, and service availability.

Tools & Materials

- Safety goggles(Protect eyes from flying debris and spray)

- Work gloves(Grip and hand protection during testing)

- Water source (garden hose or reservoir)(Adequate flow to test pump and spray)

- Air compressor (for evaluation only)(If you’re testing concepts, ensure rated safety and do not pressurize liquids without a proper pump)

- Pressure-rated hoses and fittings(Only with formal liquid-pump setups; do not improvise)

- Basic hand tools (wrench, pliers)(For inspection and adjustments, not for creating a working pressure washer)

Steps

Estimated time: Estimated total time: 2-4 hours

- 1

Assess your goal

Clarify the cleaning tasks you need to accomplish and the level of power required. This initial assessment helps you decide whether a conventional pressure washer is the right tool or if alternative approaches are better.

Tip: Document the surfaces and stains to estimate PSI/GPM needs. - 2

Review the fundamentals of a washer

Study how water pressure, flow, and nozzle size interact to remove grime. Understanding these relationships helps you evaluate whether any air-based approach can meaningfully substitute for a water pump.

Tip: Focus on pump type, not just motor size, when assessing performance. - 3

Check air compressor capabilities

If you’re exploring an air-driven concept, inventory the compressor's airflow and pressure characteristics. Remember that sustaining a water flow depends on a liquid pump, not air alone.

Tip: Avoid assuming air alone will deliver the needed water pressure. - 4

Explore safe alternatives

Research dedicated pneumatic liquid pumps or, more practically, a real pressure washer. Compare PSI, GPM, weight, and maintenance requirements, and consider warranty coverage.

Tip: Choose documented, purpose-built equipment over DIY ad hoc solutions. - 5

Plan a safe test path

If you proceed with any experimental setup, isolate the water path from the air, use pressure-rated components, and follow safety guidelines. Conduct tests with low pressure and near-field supervision.

Tip: Never circumvent safety interlocks or bypass manufacturer instructions. - 6

Decide between buy or build

Based on your tests and needs, decide whether to purchase a standard washer or pursue a specialized, professionally designed pneumatic liquid pump. DIY hybrid setups are not recommended for routine use.

Tip: Prioritize reliability, warranty, and service availability.

Quick Answers

Is it possible to convert an air compressor into a pressure washer?

Practically, no. Replacing the water pump with air pressure alone is not feasible for reliable cleaning. Any workable option would require a documented pump designed for liquids and adherence to safety guidelines.

Converting air pressure alone into water pressure isn’t practical. Use a real pump or a documented pneumatic liquid pump instead.

What is a pneumatic water pump and could it work?

A pneumatic water pump uses compressed air to drive a liquid-moving mechanism. While possible in specialized machines, it’s not a DIY solution for home cleaning and requires careful design and testing.

A pneumatic water pump can move water, but it’s not a simple DIY fix for a home washer and needs proper equipment.

What are the safety risks of trying to bench-build an air-powered washer?

Risks include hose rupture from high-pressure jets, unintended spray directions, electrical hazards near water, and contamination of seals by oil or moisture in air lines.

High-pressure sprays and electrical hazards make DIY air-to-water setups dangerous; safety gear and manufacturer guidance are essential.

What should I buy instead for effective cleaning?

Choose a purpose-built pressure washer that matches your cleaning tasks, with appropriate PSI, GPM, and nozzle options. If you need chemical delivery, look for models with detergent compatibility and safety features.

For reliable cleaning, pick a real pressure washer with the right PSI and GPM, plus proper nozzles.

Can a garden hose and nozzle replace a pressure washer for tough jobs?

A garden hose with a nozzle delivers far less water pressure and accuracy than a true pressure washer. It’s fine for light cleaning but won’t replace a high-pressure machine for stubborn grime.

A hose with a nozzle is great for light cleaning, but it can’t match a pressure washer for tough jobs.

Is there a legitimate path to mixing air with water safely?

The only safe path is to use equipment specifically designed to handle liquids with an air-assisted mechanism, following the manufacturer’s instructions and safety standards.

Only use equipment designed for air-assisted water delivery and follow safety guidelines.

Watch Video

Key Takeaways

- Define the task clearly before attempting any modifications.

- Use purpose-built equipment rather than DIY air-driven substitutes.

- Prioritize safety features and warranties when choosing gear.

- Understand water-side mechanics (pump, nozzle, flow) over air-side concepts.