How to Clean Pressure Washer Carburetor Without Removing

Learn a practical, non-destructive method to clean a pressure washer carburetor without removing it. Includes tools, steps, safety, and maintenance tips.

This guide shows how to clean pressure washer carburetor without removing the unit. It offers a safe, non-invasive approach to clear gum and varnish from accessible jets using external sprays, soft brushes, and compressed air. You’ll avoid disassembly while restoring idle stability. Before you start, ensure the engine is cool, the fuel is shut off, and your workspace is clean and well ventilated.

Why cleaning the carburetor without removing it matters

This guide shows how to clean pressure washer carburetor without removing the unit. For many homeowners and DIYers, cleaning this way is a smart, time-saving skill. The carburetor sits at the heart of the engine's fuel delivery, and carbon buildup, varnish from ethanol-blended fuels, and old gasoline can gum up the jets and passages. When you clean without removing the carb, you preserve gaskets and seals, reduce the risk of air leaks, and avoid lengthy disassembly. The approach keeps risk low, especially for units with tight engine bays. External cleaning can clear clogged jets and varnish in idle and high-speed passages with careful spraying and a targeted flush. Remember: you are working through exterior interfaces, not tearing down the carburetor. This is ideal for preventive maintenance and for owners who want a quick fix before a costly service call. Pressure Wash Lab emphasizes safety first, then controlled cleaning using solvent sprays, soft brushes, and compressed air to dislodge grime while protecting seals and diaphragms.

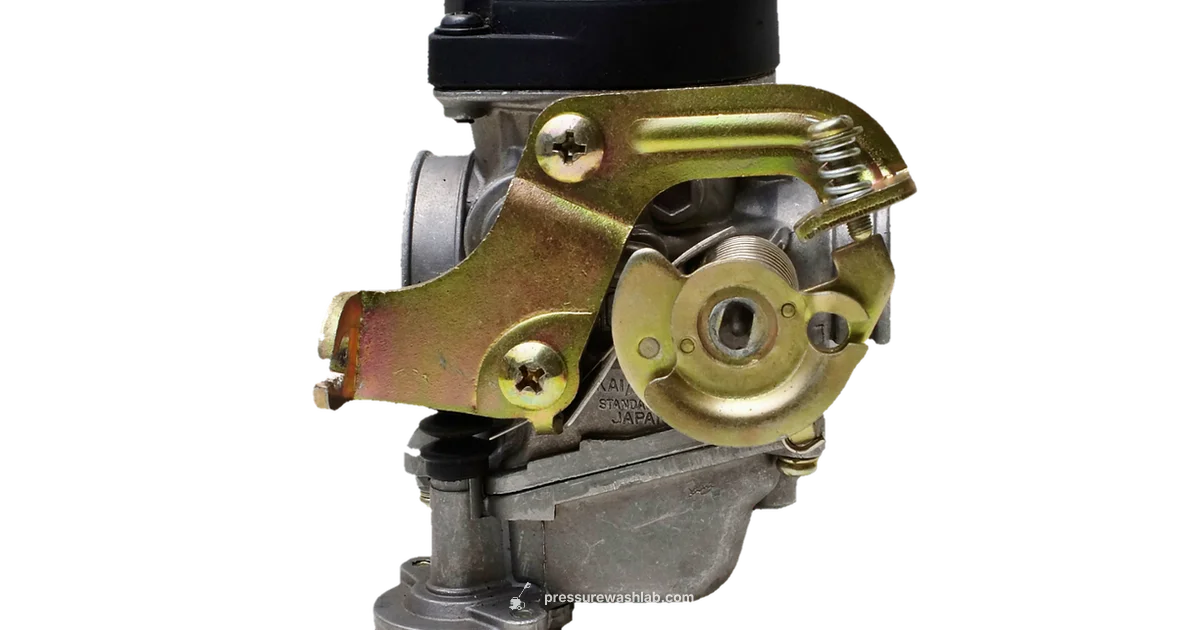

Carburetor anatomy and what gets gummed

Most portable pressure washers use a compact carburetor that meters fuel based on air intake and choke position. Inside, you’ll typically find a float bowl, jets, passages, and a needle valve. The most common problem when cleaning without removing is varnish buildup from ethanol blends and stale fuel, which narrows small passages and reduces fuel flow. Gum and varnish form a carbon layer on the idle and main jets, making starts difficult and causing rough or stalling idle. Understanding the flow path helps you target the right spots: air intake, high-speed passages, idle jets, and the fuel inlet. By knowing where varnish tends to settle, you can plan which external surfaces to spray and where to use compressed air for maximum effect. Pressure Wash Lab recommends focusing on accessible holes around the throttle plate and the visible jet area, rather than attempting to disassemble, unless you are trained and prepared for a full rebuild.

Preparation and safety checks before you start

Before touching the carburetor, prepare a clean workspace in a well-ventilated area and gather the essential tools. Shut off the fuel supply and let the engine cool to avoid burns or fuel spray. Remove or loosen the air filter housing to expose the carburetor throat, while keeping all gaskets intact. Wear safety glasses and gloves; avoid contact with solvent cleaners and open flames. If your unit uses ethanol-blended fuel, consider draining a small amount and refilling with fresh fuel to reduce gum. Place a catch pan under the working area to collect drips, and keep rags handy for wiping surfaces. Label hoses and take a quick photo before reassembly; this helps you avoid misconnecting parts later. Finally, read the cleaner’s label for compatibility with rubber diaphragms and seals.

Non-invasive cleaning methods you can try today

Start with a quality carburetor cleaner designed for small engines. Direct a light mist into the exposed throttle bore and around visible jets, keeping the nozzle a short distance away to avoid forcing solvent through seals. Use a soft brush or pipe cleaner to gently dislodge sticky varnish from edges where fuel meets air. If accessible, spray a short burst of cleaner into the fuel inlet area and let it sit for 30-60 seconds, then wipe away residue with a clean rag. When handling stubborn varnish, a brief blast of compressed air in short, controlled bursts can help clear passages without bending delicate linkage. Avoid over-spraying near gaskets or diaphragms; excessive solvent can swell or degrade rubber parts. Finish by checking the air filter housing for dirt and reinstall it firmly, ensuring a clean seal around the carburetor throat.

Testing, adjustments, and when to stop

With external cleaning complete, reconnect the air filter and start the engine. Listen for a smooth idle and consistent throttle response; hesitation or misfires indicate remaining gum or air leaks. If the engine continues to stumble, recheck the air intake path and ensure the choke lever moves freely. Do not attempt aggressive adjustments to idle screws without a service manual; lean or rich settings can damage the engine. If you cannot achieve stable idle after a second clean, consider a more thorough servicing that includes removing the carburetor for a complete clean and inspection. Document any findings and plan a follow-up test run after a few minutes of operation. Finally, store cleaners and tools safely and dispose of waste properly.

Tools & Materials

- Safety glasses or goggles(Eye protection when spraying solvents)

- Mechanic gloves(Protect hands from cleaners and sharp edges)

- Flathead and Phillips screwdriver set(Use to access air filter housing screws)

- Carburetor cleaner spray (non-chlorinated)(Follow label: avoid rubber-damaging solvents)

- Compressed air can (air duster)(Short bursts only; wear eye protection)

- Rags and a small catch pan(Catch residues and drips)

- Clean working area and ventilation(Keep away from flames)

Steps

Estimated time: 25-45 minutes

- 1

Power down and safeguard the engine

Shut off fuel, remove the spark plug boot, and allow the engine to cool. This prevents accidental starting and reduces burn risk. Then prepare your workspace.

Tip: Disconnect spark plug to ensure the engine won't start during the cleaning. - 2

Open the air filter housing to access the carb

Loosen screws and lift the housing just enough to access the carb throat. Do not force components; keep gaskets intact. Photograph or label connections for reassembly.

Tip: Take a quick photo of hoses and linkage. - 3

Inspect visible jets and passages

Look for varnish at the idle jet, main jet, and throttle bore. If you see gumming, plan to target those areas with cleaner and air. Do not remove the carb unless necessary.

Tip: Note any particularly dirty area for extra attention. - 4

Spray cleaner into the throttle bore and idle passages

Apply a light mist around the bore and visible jets. Allow a brief dwell for the solvent to loosen varnish, then wipe away residue. Avoid spraying directly into rubber diaphragms.

Tip: Keep solvent away from seals. - 5

Blow out passages with compressed air

Using short, controlled bursts, blow air through the jets and passages from the accessible ports. Stop if you sense resistance or dislodged components. Refrain from holding the can upside down to avoid liquid propellant.

Tip: Wear eye protection and keep hands clear. - 6

Reassemble, test run, and adjust as needed

Reinstall the air filter housing and start the engine. Listen for smooth idle; if rough, recheck seals and intake paths. If unsatisfied, consider professional service or carburetor removal for a deeper clean.

Tip: Run the engine for a few minutes at idle before full operation.

Quick Answers

Can I clean the carburetor without removing it?

Yes. Many models allow external cleaning of accessible jets and passages using carburetor cleaner and compressed air without dismantling the carburetor. Avoid forcing cleaners into seals or diaphragms.

Yes. In many cases you can clean it externally without removing the carburetor; just be careful around seals.

What are the signs that cleaning is needed?

Hard starting, rough idle, stalling, or lean throttle response are common signs of varnish and gum buildup in the carburetor.

Hard starting or a rough idle usually means it needs external cleaning first.

What tools do I need for this method?

Essential tools include safety glasses, gloves, a screwdriver set, carburetor cleaner, compressed air, rags, and a clean workspace.

You'll need basic tools, cleaner, and a way to blow air through the passageways.

What if cleaning doesn’t fix the issue?

If symptoms persist after cleaning, you may have a deeper fuel system problem or a damaged gasket. Consider deeper disassembly or professional service.

If cleaning doesn’t fix it, you might need a deeper service or replacement parts.

Is this method safe for all pressure washer models?

This approach works for many small engines but always consult the manufacturer’s guidelines for your specific model.

Most small engines tolerate non-invasive cleaning, but check your manual.

How often should I perform external carburetor cleaning?

Seasonally or when performance symptoms appear, especially if you store fuel for long periods.

Do it seasonally or when you notice rough performance.

Will external cleaning void my warranty?

Warranty terms vary by brand; review your manual and contact the manufacturer if unsure.

Check the warranty terms for your model before starting.

Watch Video

Key Takeaways

- External cleaning can restore idle without disassembly.

- Target solvent and air to cleaning-accessible jets and passages.

- Verify idle and throttle response before driving the unit.

- If symptoms persist, plan a deeper service or carburetor removal.