How to Install a Pressure Washer Nozzle: A Practical Step-by-Step Guide

Learn how to install a pressure washer nozzle safely and correctly. This guide covers nozzle sizes, compatibility, step-by-step installation, safety tips, and maintenance to maximize efficiency and protect your surfaces.

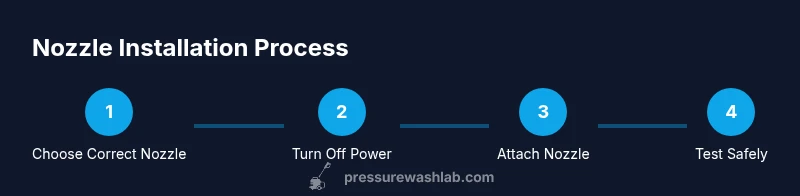

Install a pressure washer nozzle safely and correctly by matching the tip to the task, then connecting it firmly to the wand and testing with the water off. This quick guide covers choosing the right nozzle size, proper connection methods, and basic safety checks to prevent leaks or injuries. Follow the steps to avoid common mistakes.

Why nozzle choice matters for safety and results

The nozzle tip on your pressure washer does more than just spray water; it defines the PSI concentration, the contact area, and the risk profile for each surface you treat. A mismatch between nozzle and surface can cause etching, spatter, or damage to wood, paint, or concrete. The Pressure Wash Lab team emphasizes that choosing the right nozzle tip is a foundational step in any project. By starting with the task in mind—light cleaning, aggressive stain removal, or delicate surface care—you set the stage for a safer, faster, and more efficient cleaning session. In this section, you’ll learn how nozzle angles work, how to interpret spray patterns, and how to align your choice with your equipment's capabilities. Following best practices reduces wear, extends equipment life, and improves results.

Understanding nozzle sizes and spray patterns

Nozzle sizes are defined by spray angles and tips. A 0-degree nozzle concentrates water into a tiny, high-pressure stream, useful for stubborn grime on hard surfaces but risky for softer materials. A 15-degree nozzle blends precision and safety, while 25-degree and 40-degree tips offer wider spray patterns ideal for broader surfaces and gentler cleaning. Different brands color-code tips, and some wands accept only specific quick-connect fittings. Always consult your owner’s manual and rely on your judgment to match the nozzle to the task. The right nozzle balance improves cleaning efficiency, reduces surface damage, and extends the life of your equipment.

Safety prerequisites and workspace setup

Before you touch any nozzle, prepare the workspace and PPE. Clear the area of bystanders, wear safety goggles and gloves, and wear sturdy footwear with good traction. Ensure your water supply is clean and connected, and that the washer is on a level, stable surface to prevent slips. Have a rag handy to wipe off any drips, and keep a bucket or drain nearby for overflow. Taking these precautions minimizes accidents and protects your surfaces from unintended impact or overspray.

Inspecting nozzle and fittings before installation

Carefully inspect the nozzle tip for cracks, chips, or wear. Check the wand fitting and threads for damage and corrosion. If the fitting shows any signs of wear, replace it before proceeding. A damaged nozzle or loose threads can cause leaks, poor spray performance, or sudden disconnections under pressure. If you notice cross-threading, stop and replace the old hardware to avoid further harm.

Step-by-step preparation: gather tools and confirm compatibility

Collect the tools and parts you’ll need and confirm your nozzle is compatible with your wand and pump. Separate nozzles by spray angle and ensure the connection type on your wand matches the nozzle (quick-connect or threaded). Having a dedicated workspace and a small tray for tips helps prevent loss or mix-ups. Double-check the manufacturer’s recommendations for maximum PSI and compatible accessories to avoid accidentally overloading the system.

Step 1 - power off and relieve pressure

Power off the unit and disconnect from the electrical supply if applicable. Shut off the water supply and release pressure by briefly triggering the spray away from people or objects. This relieves built-up pressure in the hose and pump, reducing the risk of a sudden nozzle blow-off. Do not attempt to change nozzles while the machine is under pressure to avoid injuries or equipment damage.

Step 2 - remove old nozzle and inspect threads

If you’re replacing an old nozzle, carefully unscrew it by hand first, then use a wrench only if necessary. Inspect the threads on the wand for damage; cross-threading can ruin the connection and create leaks. Clean the male and female threads with a dry rag to remove debris that could prevent a proper seal. If threads are worn, replace the wand or the nozzle adapter before continuing.

Step 3 - install new nozzle and secure connections

Select the correct nozzle for the task and slide it onto the wand’s connection until it seats. For quick-connect fittings, push firmly until it clicks; for threaded fittings, tighten by hand and finish with a gentle snug using a wrench—do not overtighten. Check that the nozzle is oriented correctly and fully engaged before testing. Misalignment can lead to poor spray, leaks, or nozzle detachment under pressure.

Step 4 - test and verify spray pattern safely

With the nozzle installed, reattach the water supply and briefly run the unit at low pressure away from people and fragile surfaces. Inspect for leaks at the connection and verify the spray is consistent and centered. If the pattern is skewed or spraying unevenly, re-seat the nozzle or try a different angle. Gradually adjust to the desired setting while maintaining safe distance from the surface.

Maintenance, storage, and safety reminders

After use, flush the system with clean water and dry the nozzle to prevent mineral buildup. Store nozzles separately in a dry, labeled container to prevent cross-contamination of tip sizes. Periodically inspect nozzles for wear and replace worn tips promptly. Always recheck connections before your next cleaning session to ensure safe operation and long nozzle life.

Authoritative sources and safety guidelines

For deeper safety guidelines, consult authoritative sources such as OSHA and CDC-NIOSH. These organizations provide general safety practices for handling high-pressure equipment and household tools. While they don’t substitute for brand-specific instructions, they offer valuable context on protective gear, safe handling, and incident prevention. Always follow local regulations and the manufacturer’s directions to maintain safe operation.

Brand guidance and final notes

Pressure Wash Lab emphasizes that nozzle installation is not merely a mechanical task; it’s a safety-critical procedure that protects you, your surfaces, and your equipment. Adhering to best practices helps you complete jobs more efficiently and with fewer surprises. Keep learning, test responsibly, and refer to manufacturer recommendations for your specific unit.

Authoritative sources references

- OSHA: https://www.osha.gov

- CDC/NIOSH: https://www.cdc.gov/niosh

- Extension services: https://extension.illinois.edu

Tools & Materials

- Pressure washer nozzle(Choose the correct size (e.g., 0°, 15°, 25°, 40°) based on the task and surface)

- Wand with compatible quick-connect or screw-on end(Ensure compatibility with your unit’s fittings)

- Owner's manual or manufacturer guide(Verify PSI limits and compatible accessories)

- Protective gloves(Cut-resistant if possible; protect hands from high-pressure spray)

- Safety goggles(Eye protection required during testing and changes)

- Rag or shop towels(For wiping leaks and keeping work area clean)

- Pliers or adjustable wrench(For stubborn fittings, do not over-tighten)

- Thread sealant tape (PTFE) or compatible sealant(Only if required by wand/nozzle manufacturer)

- Clean work surface(Flat, dry area away from people and pets)

Steps

Estimated time: 15-30 minutes

- 1

Power off and relieve pressure

Power down the unit and disconnect from power if applicable. Shut off the water supply and trigger the spray away from people or objects to release pressure. This prevents a sudden nozzle release and keeps you safe during the swap.

Tip: Relieving pressure before changing nozzles is a non-negotiable safety step. - 2

Inspect the current setup

Check the wand and existing nozzle for wear or damage. Note the connection type (quick-connect or threaded) to ensure you pick the correct replacement. Clean any debris from threads before removal.

Tip: A clean, dry connection helps ensure a solid seal. - 3

Remove the old nozzle

Gently unscrew or pull off the current nozzle, depending on your wand. If resistance occurs, stop and verify there’s no cross-threading. Replace worn hardware before continuing.

Tip: Hand-tighten during removal to avoid thread damage. - 4

Prepare the new nozzle

Select the appropriate nozzle for the task and inspect its threads. Wipe threads clean and inspect seating surfaces to ensure a flat, undamaged contact. If using a sealant, apply only as instructed by the manufacturer.

Tip: Do not mix sealants with incompatible fittings. - 5

Attach the new nozzle

Slide on or thread the new nozzle until it seats fully. For quick-connects, push until you hear a click; for threads, tighten by hand then snug with a wrench without over-tightening.

Tip: A snug fit prevents leaks and premature detachment. - 6

Check alignment and pattern

Ensure the nozzle is oriented correctly and test the spray at a safe distance on a non-damageable surface. Observe the pattern and adjust angle if needed.

Tip: Small changes in angle can drastically affect coverage. - 7

Test under light load

Reconnect the water supply and run the system briefly at low pressure. Look for leaks at the connection and confirm even spray across the target area.

Tip: If leaks appear, shut down and reseat the nozzle. - 8

Evaluate surface safety

Proceed with the task at a conservative pressure and distance appropriate for the surface. Avoid etching surfaces like stucco or soft wood.

Tip: When in doubt, start with a wider angle and lower pressure. - 9

Document and store

Record the nozzle size and date of maintenance. Store tips separately in a dry, labeled container to prevent mix-ups.

Tip: Label tips by angle and PSI compatibility. - 10

Final safety check

Do a final pass to verify all connections are secure and the area is safe for operation. Return tools to the storage area and clean the workspace.

Tip: A quick post-task check prevents late-stage issues.

Quick Answers

Do I need to power off the pressure washer before changing nozzles?

Yes. Always turn off the unit and relieve pressure before removing or installing a nozzle to prevent injuries or a sudden, high-velocity release.

Yes. Power off and relieve pressure before changing nozzles to stay safe.

Can I use any nozzle with any pressure washer?

No. Check your machine’s manual for compatible nozzle types and PSI limits. Using an incompatible nozzle can damage fittings or void warranties.

No. Check compatibility in the manual before choosing a nozzle.

What nozzle size is best for concrete cleaning?

For concrete, you’ll typically start with a wider spray angle like 25° or 40°. Adjust based on stain severity and surface tolerance, always testing on a small area first.

Start with a wider spray for concrete and test on a small area.

Why does my nozzle leak after installation?

A leak usually means a loose connection or worn threads. Re-seat the nozzle, clean the threads, and replace any damaged parts before testing again.

Leaks usually mean a loose fit or damaged threads—re-seat and inspect.

How can I tell if my nozzle is compatible with my wand?

Consult the wand’s manual for compatible nozzle types and connection standards. If in doubt, contact the manufacturer or a professional.

Check the manual for compatibility or contact the manufacturer.

What maintenance should I perform after nozzle installation?

Rinse the system, dry the nozzle, and store in a dry place. Periodically inspect for wear and replace worn parts.

Rinse and dry after use, then store properly and inspect for wear.

Watch Video

Key Takeaways

- Choose the correct nozzle for the task

- Relieve pressure before changing tips

- Ensure secure connections to avoid leaks

- Test spray patterns before cleaning sensitive surfaces

- Store nozzles properly to extend life