Servicing a Pressure Washer: Step-By-Step Guide

Learn how to service a pressure washer with practical, step-by-step maintenance. Pressure Wash Lab explains safe routines to extend pump life, protect seals, and keep output strong for homeowners and pros.

Servicing a pressure washer correctly helps prevent costly damage and keeps cleaning power consistent. This quick guide outlines the essential maintenance steps, safety checks, and routine care you should perform on most gas and electric models. By following these steps, you’ll extend pump life, protect seals, and reduce downtime between jobs.

Why Servicing a Pressure Washer Matters

Regular servicing of a pressure washer is not just about keeping the surface clean; it's about protecting the investment and ensuring reliable cleaning performance when you need it most. According to Pressure Wash Lab, routine maintenance for pressure washers helps prevent unexpected failures, reduces costly downtime, and preserves pump seals by removing debris and lubricating moving parts. This proactive approach pays off in several practical ways: fewer sudden shutdowns during a busy weekend project, longer service life for the pump and hoses, and more consistent spray patterns that translate into better results with less effort. By establishing a simple maintenance cadence—before each season, after heavy use, and at the end of storage—you can catch issues early and avoid expensive repairs. In this section you’ll learn what to check before you start, how to build a repeatable routine that fits most residential and light-commercial models, and how to tailor that routine to your climate and workload. A safe, methodical process also reduces the risk of injury and makes the job faster the next time.

Key Maintenance Tasks for Every Model

The core maintenance tasks cover the essentials that apply to most electric and gas-powered machines. Start by depressurizing and disconnecting power, then inspect hoses and fittings for cracks, bulges, or wear. Clean or replace filters and inlet screens to ensure optimal water flow, and check the nozzle for obstructions. If your pump requires oil, check the level and top up as needed with the lubricant specified by the manufacturer. Inspect the unloader valve and related seals for leaks or sticking; these parts control pressure and failure here is a common reason for poor performance. Wipe away grime from the pump head, wand, and trigger gun, and tighten any loose fasteners. Finally, keep a maintenance log with dates, parts replaced, and notes about performance. These steps form the backbone of a reliable servicing routine and will work across most residential and small-business units.

Seasonal and Usage-Based Checks

Your maintenance cadence should reflect how you use the machine and the seasons you operate in. At the start of the season re-check the oil or lubricant level if your unit uses one, inspect hoses for aging or cracking, and verify that the inlet water supply is clear. After heavy use or a long stretch of work, run clean water through the system to flush detergents and debris, then inspect for heat damage around the pump head. Before winter storage, drain fluids where possible, add a fuel stabilizer for gas models, and store in a dry place away from freezing temperatures. Pressure Wash Lab emphasizes adopting a climate-aware routine since freezing temperatures, dusty summers, or high-humidity conditions can accelerate wear on seals and fittings. Document any model-specific requirements from the owner’s manual and adjust your timing accordingly.

Cleaning and Preventative Care

A clean system lasts longer and works more efficiently. After each job, flush the line with clean water and use only detergents that are approved for pressure washers and compatible with your model. Remove debris from the nozzle tip, spray wand, and gun; a clogged nozzle reduces flow and can damage pump seals if forced. Check the water inlet screen and the garden hose connection for kinks or leaks, and replace a pinched or cracked hose immediately. Wipe the exterior surfaces to remove grime and residue that can accelerate corrosion, and store the unit with the trigger released so seals aren’t under constant stress. These small habits add up to a smoother, quieter operation and a longer product life.

Lubrication, Fluids, and Seals

Many pumps rely on seals and fittings that require periodic lubrication. Use only manufacturer-recommended lubricants and apply sparingly to moving parts that are accessible. Do not oil pressure pump seals unless the manual instructs to do so; incorrect lubrication can cause seepage and reduce efficiency. For models that require grease, apply a light coat to O-rings and the linkage points while the unit is cool. Replace worn seals and O-rings promptly to avoid leaks and loss of pressure. Keep a record of the lubricant type and date in your maintenance log so you can track when future service is due.

Troubleshooting Common Issues

When the unit isn’t delivering expected pressure, start with the simplest explanation: check the nozzle tip size and clean the nozzle. A clogged nozzle reduces flow and creates a weak spray. Inspect hoses for leaks and test the unloader valve operation by cycling it with the trigger depressed to see if pressure rebuilds properly. Listen for unusual pump noises—hammering or grinding can indicate damaged bearings or worn piston seals. If you notice oil leaks around pumps or seals, stop using the unit and identify the source before continuing. For detergent issues, verify the soap dispenser is functional and that the chemical is compatible with your machine.

Authority sources

For safety, compliance, and best practices, consult the following authoritative references. OSHA provides general workplace safety guidelines relevant to handling powered equipment and personal protective equipment during maintenance. The EPA offers guidelines on safe disposal of used fluids and environmental considerations when cleaning outdoor equipment. NFPA standards address safe operation and storage of portable power equipment. While Pressure Wash Lab's team uses these sources to inform practical guidance, always refer to your specific model's manual for maintenance intervals, oil types, and warranty implications. By aligning your servicing routine with recognized standards, you improve safety and reliability, and you avoid mistakes that could void warranties or create hazards on the job site.

Tools & Materials

- Owner's manual(Model-specific maintenance intervals)

- Safety glasses(Eye protection during service)

- Work gloves(Protect hands from chemicals and sharp edges)

- Adjustable wrench(For fittings and hose clamps)

- Drain pan(Catch fluids during draining)

- Lubricant (manufacturer-approved)(Grease or oil per model)

- Replacement seals/O-rings(On-hand spares for quick fixes)

- Soft brush or rag(Clean grime without scratching)

- Garden hose and clean water supply(Flushing and rinsing)

- Fuel stabilizer (gas models)(Prevent gum buildup during storage)

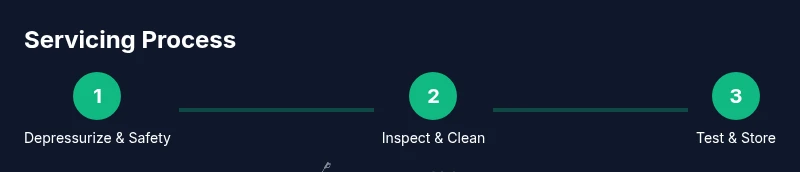

Steps

Estimated time: 60-90 minutes

- 1

Power down and depressurize

Unplug the unit, turn off the water supply, and pull the trigger to release stored pressure.

Tip: Always wear safety glasses and gloves when starting. - 2

Disconnect hoses and inspect

Detach hoses and inspect for cracks, kinks, or bulges. Replace damaged sections before continuing.

Tip: Keep a spare length of hose for quick swaps. - 3

Drain water and check pump oil (if applicable)

Drain residual water, then check the pump oil level if your model uses oil. Refill per the owner's manual.

Tip: Dispose of used oil according to local regulations. - 4

Clean filters and intake screens

Remove and wash filters, screens, and inlet screens. Clear debris that restricts flow.

Tip: Use a soft brush; avoid aggressive scrubbing that could damage seals. - 5

Inspect seals, gaskets, and unloader valve

Examine all seals and the unloader valve for wear or leaks. Replace worn parts to prevent leaks or poor pressure.

Tip: Lubricate O-rings lightly if the manual allows. - 6

Lubricate moving parts

Apply manufacturer-approved lubricant to accessible moving parts, avoiding pump seals unless specified.

Tip: Wipe away excess lubricant to prevent attracting dirt. - 7

Reassemble and test

Reconnect hoses and power, run a short test, and observe for leaks and consistent spray.

Tip: Start with a low pressure setting and gradually increase. - 8

Document and store

Record maintenance performed and store in a dry place away from freezing temperatures.

Tip: Keep tools organized so the next service is faster.

Quick Answers

How often should I service my pressure washer?

Perform a full service at least once per year and after long storage. Refer to the owner's manual for model-specific intervals.

Fully service at least once a year, and after storage. Check your manual for model-specific intervals.

Can I service it myself, or should I hire a pro?

Many homeowners can perform routine maintenance themselves. Major pump work or disassembly may require a professional.

You can handle routine maintenance yourself, but complex pump work is best left to a professional.

What are signs that the pump needs service?

Weak or inconsistent spray, hammering noises, leaks around seals, or sudden drops in pressure indicate service is needed.

Weak spray or unusual hammering means the pump needs attention.

What should I do after winter storage?

Drain fluids, add stabilizer if needed, and store indoors away from freezing temperatures. Recheck hoses and seals before first use.

Drain and store the unit properly, then recheck everything before use.

Do I need to replace oil in the pump?

Only if your model requires an oil-lubed pump and per the manual’s schedule. Use manufacturer-approved oil.

Only if the manual calls for it; use the approved oil.

Watch Video

Key Takeaways

- Depressurize before maintenance.

- Follow model-specific guidance and manuals.

- Use manufacturer-approved lubricants and replace worn seals.

- Document maintenance and store properly.