How to Clean a Pressure Washer: Step-by-Step Guide

Learn how to clean your pressure washer safely and effectively. This maintenance guide covers exterior cleaning, nozzle care, fluid management, and proper storage to extend pump life for gas and electric units.

This guide shows you how to clean your pressure washer thoroughly and safely. You’ll disconnect power, drain fluids, clean the nozzle and filter, flush with clean water, inspect hoses, and store properly. Following these steps helps extend pump life and maintain performance, whether you use a gas, electric, or powered unit.

Why Regular Cleaning Matters

Keeping a pressure washer clean isn’t just about cosmetics. Over time, dirt, minerals, and detergent residue can clog filters, degrade seals, and reduce efficiency. According to Pressure Wash Lab, a regular cleaning routine helps maintain performance and extends pump life by preventing buildup that can lead to overheating or leaks. When you remove grime from the intake screen, cooling passages stay clear and the nozzle maintains consistent pressure. In practice, a focused cleaning after each heavy use saves time and money on repairs and downtime. A clean unit also prevents corrosion on metal components and reduces the risk of stubborn clogs in the high-pressure hose. Regular maintenance is the best defense against unexpected failures on the job.

Safety and Prep

Before you touch any moving parts, ensure the unit is powered off, unplugged, and cool. Put on safety glasses and gloves to shield your eyes and skin from splashes and sharp edges. Work in a well-ventilated area, have a bucket of clean water and towels handy, and keep a trash bin nearby for used rags. If you’re cleaning a gasoline-powered unit, perform this task outdoors in a ventilated area away from sparks. Safety is non-negotiable because a rushed clean can lead to injuries or accidental starts.

External Cleaning and Exterior Care

Clean the housing, wand, and spray nozzle exterior with a mild soap solution and a soft brush or cloth. Rinse gently with clean water, avoiding high-pressure streams directly into vents, seals, or the pump area. A quick wipe-down after use removes detergent residues that can attract dirt and cause clogs. Pressure Wash Lab analysis notes that debris on the intake screen can reduce airflow and cooling, which emphasizes why you should inspect and clean these areas regularly as part of your routine.

Internal Cleaning and Fluid Management

If your unit is gasoline-powered, drain old fuel and check oil levels before reassembly. Electric models typically require flushing the water lines with clean water to prevent mineral buildup. Remove and rinse the inlet filter, and if your model has a detergent siphon, flush it with water to clear any soap residue. After cleaning, refill fluids to the manufacturer’s recommended levels and reconnect hoses carefully. Internal cleaning helps prevent pump wear and ensures consistent performance when you reconnect to power.

Storage, Maintenance Schedule, and Troubleshooting

Dry all components completely to prevent rust and mold. Store the unit off the ground in a dry area, with hoses coiled loosely to avoid kinks. Create a simple maintenance calendar: after each job, perform external cleaning and exterior checks; every 3–6 months, do a deeper internal flush and filter inspection; keep an eye on seals, O-rings, and connectors for signs of wear. If you notice reduced pressure, unusual noises, or leaks, revisit the steps above and consult the manual. The Pressure Wash Lab team emphasizes keeping a written log of maintenance tasks for easy reference.

Tools & Materials

- Safety gloves(Non-slip grip for handling hoses and chemicals)

- Safety glasses(Eye protection against splashes)

- Soft-bristled brush(Use for exterior grime without scratching surfaces)

- Mild dish soap(Gentle cleaner for exterior components)

- Buckets and towels(For rinsing and absorbing spills)

- Garden hose or access to clean water(Rinse and flush lines)

- Rags or shop paper(Drying and wiping sensitive parts)

- Funnel (optional)(Helpful when refilling fluids)

- Basic oil and fuel (if applicable)(Only for gas-powered units per manufacturer)

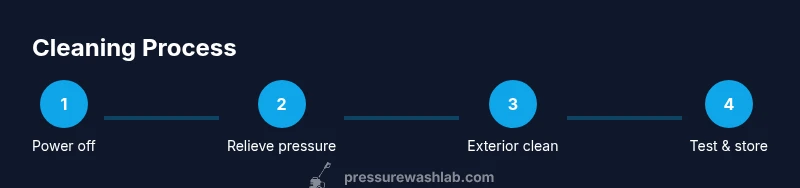

Steps

Estimated time: 40-60 minutes

- 1

Power off and allow to cool

Turn off the unit, unplug electric models, or shut off gas supply. Let the machine cool for at least 10 minutes to avoid burns and component damage. This ensures safe handling during cleaning.

Tip: A cool unit reduces the risk of warping hoses or burning your hands. - 2

Relieve pressure

Release trapped pressure by squeezing the trigger wand until steady water flow stops. Releasing pressure prevents sudden sprays and makes subsequent steps safer.

Tip: Keep a bucket handy in case of residual spray. - 3

Drain and assess fluids

For gas-powered units, drain old fuel and check for water in the fuel line if present. For electric units, ensure the water reservoir or supply line is emptied as recommended by the manual.

Tip: Dispose of fluids according to local regulations. - 4

Clean exterior and wand

Mix a mild soap solution and scrub the exterior surfaces with a soft brush. Rinse from top to bottom to prevent dirty water from recontaminating cleaned areas.

Tip: Avoid spraying soap into vents or seals. - 5

Inspect and clean nozzle and intake

Remove the nozzle tip and clean any mineral buildup. Check intake screens for debris and rinse them under running water.

Tip: Use a pin or small brush to gently clear any obstructions. - 6

Flush lines and clean filters

If your unit has a detergent line or filters, flush them with clean water to remove soap residue and debris. Clean or replace the inlet filter as needed.

Tip: Don’t use harsh solvents that could damage seals. - 7

Replenish fluids and reconnect

Reinstall or refill any fluids to the manufacturer’s specifications. Reconnect hoses and fittings securely to prevent leaks.

Tip: Double-check hose clamps and quick-connect fittings. - 8

Test run and final check

Turn the unit on and run at low pressure over a safe test surface to ensure everything works, listening for unusual sounds or leaks. Stop if anything seems off and recheck connections.

Tip: Proceed to a full task only after a successful test. - 9

Dry, store, and schedule next clean

Wipe dry, store in a dry place, and note the next maintenance date in your log. Proper drying prevents rust and keeps seals pristine.

Tip: Store with hoses loosely coiled to prevent kinks.

Quick Answers

Can I use bleach or solvents to clean a pressure washer?

Most manufacturers advise avoiding harsh solvents or bleach that can damage seals and hoses. Use mild soap and water, and follow your manual for any approved cleaners. If in doubt, contact the manufacturer or a professional.

Avoid bleach and harsh cleaners unless the manual approves them; stick to mild soap and water, and consult the manual if unsure.

Is it necessary to flush detergent lines after cleaning?

Flushing detergent lines after cleaning helps prevent residue from drying and clogging the system. If your unit lacks a detergent line, simply flush with clean water through the wand to clear any soap remnants.

Yes, flush detergent lines after cleaning to prevent residue from causing clogs, and rinse with clean water if you don’t use a detergent line.

Should I run water through the system before storage?

Yes. Run clean water through the system briefly to flush out soap and minerals, then dry all components completely before storing.

Run clean water through, then dry everything thoroughly before storage.

Is outdoor storage safe for a pressure washer?

Outdoor storage is acceptable if the unit is protected from the elements and moisture. Prefer a dry, sheltered spot and keep fuel stored safely away from heat sources for gas models.

Store in a dry, sheltered spot if possible and keep fuel away from heat.

What should I do if I notice leaks after cleaning?

If you see leaks, inspect every connection, hose, and seal for wear or damage. Tighten fittings carefully and replace any worn parts before reusing the unit.

Check all connections for leaks, tighten as needed, and replace worn parts before using again.

How often should I clean my pressure washer?

Clean the exterior after each job and perform a deeper internal check every few months, or after heavy use. Refer to the manual for the recommended maintenance schedule specific to your model.

Clean after each job, and do a deeper check every few months based on the manual.

Watch Video

Key Takeaways

- Power off and depressurize before any maintenance

- Clean exterior, nozzle, and intake to prevent buildup

- Flush lines and inspect filters for optimal flow

- Dry thoroughly and store properly to extend life

- Document maintenance dates for a reliable routine