How to Check a Pressure Washer Unloader Valve

A complete, safety-focused guide on how to check a pressure washer unloader valve for proper function, leaks, and wear. Includes tools, step-by-step diagnostics, maintenance tips, and when to replace.

You will learn how to check your pressure washer unloader valve for proper pressure relief, leaks, and sticking components. By following safety steps, identifying symptoms, and performing a guided inspection, you can diagnose whether the valve needs service or replacement. This guide covers tools, steps, and safety precautions.

What is an unloader valve and why check it?

An unloader valve is a critical safety and performance component on most high-pressure washers. It redirects pressurized water away from the nozzle and back into the pump when you release the trigger, helping regulate system pressure and prevent motor strain. When this valve isn’t functioning correctly, you can see excessive pressure, reduced spray reach, or frequent shutdowns. By learning how to check pressure washer unloader valve, you can diagnose whether the issue is valve-related or caused by hoses, o-rings, or the pump itself. According to Pressure Wash Lab, the unloader valve is the pressure-relief mechanism that directs water back to the pump when the trigger is released. A healthy valve improves efficiency, protects seals, and extends the life of the pump. In many units, a failed or dirty valve will show symptoms such as erratic pressure, leaks at the valve cap, or a lingering pump build-up after you release the trigger. Understanding where the valve sits and how it should move will make the diagnosis faster and safer, especially for DIY enthusiasts who rely on clear, repeatable checks. Different brands use cartridge, diaphragm, or piston designs, but the basic principle is the same: the valve routes water away from the nozzle once the trigger is released. Regular inspection helps catch wear, cracks, or debris before they become bigger problems.

Symptoms that point to unloader valve issues

Recognizing the signs of a faulty unloader valve is the first step in how to check pressure washer unloader valve. Look for erratic or excessively high pressure, which can cause the spray to surge or spike unpredictably. A noticeable drop in peak pressure or a loss of overall performance can also indicate valve trouble. Leaks around the valve cap or at fittings are common red flags, as is a valve that sticks in the closed or open position, preventing normal pressure relief. If you notice the pump running hot or cycling on and off without user input, this can be another symptom of a misbehaving unloader mechanism. If you’ve recently replaced hoses or seals and the behavior began afterward, the unloader valve is a good candidate for inspection. Documenting symptoms helps you decide whether a cleaning, reseal, or replacement is needed. Lastly, any unusual sounds—hissing or popping noises from the valve area—should prompt a closer look. These signals help you perform targeted diagnostics rather than guesswork. Remember, consistent symptoms across multiple starts often indicate a valve-related issue rather than a single loose hose.

Safety first: essential precautions before you start

Before you begin any inspection, prioritize safety. Disconnect power or engine kill switch, unplug if electric, and turn off the gas supply if your unit is gas-powered. Relieve all pressure by pulling the trigger with the wand pointed safely away from you and others. Wear eye protection and gloves, and work in a well-ventilated area. If your unit is mounted or heavy, secure it to prevent movement during testing. Keep a fire extinguisher nearby if you’re working around engines. Never work on a live system with pressurized water in the line. Having a clean workspace, a flashlight, and a small container for fasteners will help you stay organized and reduce the risk of losing parts during disassembly. When in doubt, consult the user manual for model-specific instructions. Safety is the foundation of effective troubleshooting and long-term reliability.

Understanding valve designs and what to expect

Unloader valves come in several designs, including diaphragm, piston, and cartridge types. The design can affect how you inspect and service them. Diaphragm valves may show wear around the diaphragms; piston valves can exhibit sticking or misalignment; cartridge valves might leak at the seal faces. Regardless of design, the basic checks are similar: look for obvious damage, confirm the valve moves freely, and ensure the bypass path opens when the trigger is released. Your inspection should consider the valve’s mounting orientation, accessibility, and the presence of protective covers. With the right approach, you can identify whether loss of pressure is due to the valve itself or ancillary parts, such as O-rings, seals, or the pump.

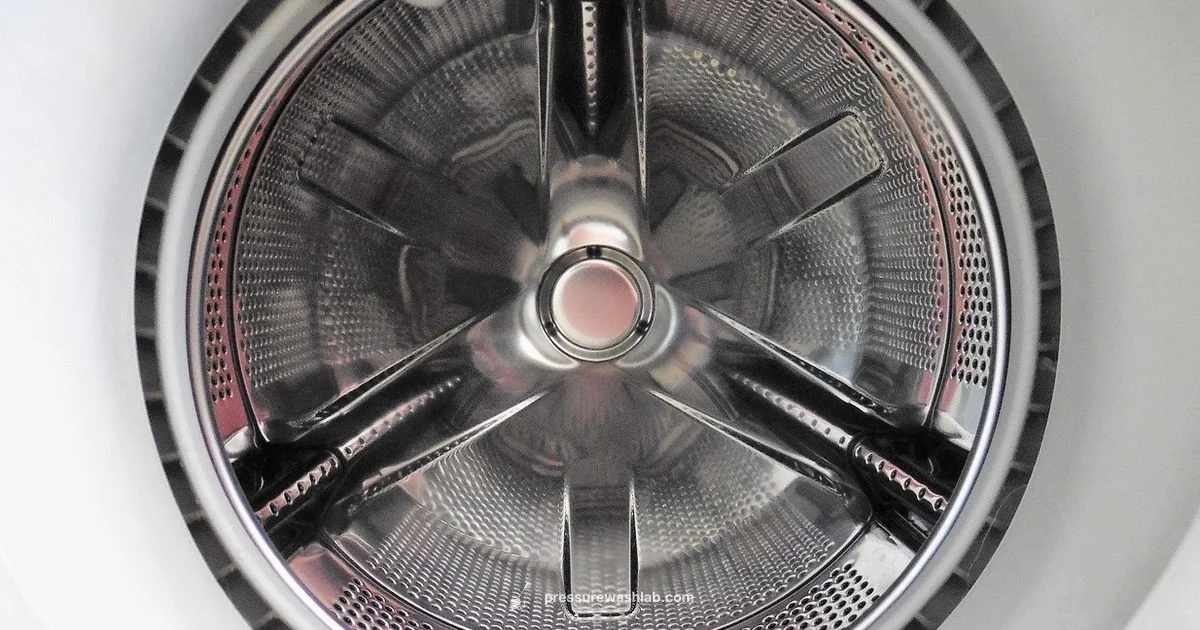

Locating the unloader valve on common pressure washers

The unloader valve is typically mounted on or near the pump body, often close to the outlet fitting. In some layouts, you’ll find it beneath a protective shroud or behind a small access plate. The valve may be cylindrical with a cap or a small block with a spring-loaded plunger. If your unit uses quick-connect spray guns, the valve could sit just upstream of the wand connection. If you can’t locate it by touch, consult the model’s schematic in the user manual or the manufacturer’s website. Knowing the exact location speeds up diagnosis and reduces unnecessary disassembly. Take care not to apply force to fragile housings or to pry at seals, which can cause additional leaks.

Visual inspection and preliminary tests you can perform without disassembly

Start with a careful external inspection. Look for cracks in the valve body, corrosion around fittings, and any signs of oil or grease that may indicate seal failure. Check for loose fasteners and inspect the cap for distortion. Gently wiggle the valve (if safe to do so) to detect looseness. With the wand pointed away, trigger the spray and observe the current behavior. A quick, initial test can reveal if the valve is not moving correctly or if the system is bypassing too early. If you see leakage at the cap or fittings, you likely need to reseal or replace components rather than the entire valve. Document your observations to guide the next steps.

Step-by-step disassembly and diagnostic checks (advanced)

If external checks point to a valve issue, prepare for a careful disassembly. Remove the valve cap following the manufacturer’s instructions, then inspect the internal components: the spring, diaphragm, and seals. Use appropriate tools to avoid damaging threads or faces. Look for cracks, bent parts, or hardened diaphragms. Clean all parts with mild soapy water or a parts-safe solvent, and dry thoroughly before reassembly. Reinstall the cap snugly without over-tightening. After reassembly, perform a controlled test at low pressure to verify operation and ensure there are no leaks. Keep the workspace organized and replace any worn components with manufacturer-approved parts.

How to test after reassembly and what constitutes a successful result

Once reassembled, test the unit at low pressure first to confirm that the unloader valve moves smoothly and that the system builds pressure normally. If the valve returns to bypass quickly when you release the trigger, tests should show stable maximum pressure within the expected range. If pressure remains high or a leak persists, re-check the valve seating or replace worn seals. A successful test shows consistent performance across multiple cycles and no leaks around the cap or fittings. If issues recur, it may be more cost-effective to replace the valve or consult a pro.

Maintenance and preventive care to extend valve life

Regular maintenance can extend the life of the unloader valve. Schedule periodic inspections, keep the valve clean from debris, and replace worn seals proactively. Use fresh, clean water and avoid running the washer dry, which can damage seals. When connecting hoses, ensure fittings are tight but not over-torqued. Keep spare O-rings and diaphragms on hand for quick reseals. Finally, adhere to manufacturer-recommended service intervals and use only approved parts. Preventive care reduces downtime and prolongs pump life.

Tools & Materials

- Safety glasses(Impact-rated, ANSI Z87.1 compliant)

- Work gloves(Durable, non-slip gloves)

- Mechanic's screwdriver set(Flathead and Phillips sizes common to pump hardware)

- Wrench set(Open-end or adjustable; ensure correct size for fittings)

- Rags and a small container(Secure small parts and clean spills)

- Replacement O-rings/diaphragm kit(Have on hand in case of wear)

- Penetrating oil(Useful for stubborn fittings)

- Dimensional calipers or a ruler(For measuring worn components if needed)

Steps

Estimated time: 30-60 minutes

- 1

Power down and unplug

Turn off the unit and disconnect the power. If you have a gas-powered model, switch off the engine and remove the spark plug boot to ensure it cannot start. Relieve internal pressure by pulling the trigger on the spray wand until the stream stops.

Tip: Never work on a live system. Double-check that the wand is depressurized before touching valve hardware. - 2

Relieve stored pressure

With the wand pointed away from you and others, press and hold the trigger to release any remaining pressure in hoses and the pump. Do this slowly to avoid a spray burst.

Tip: If pressure seems stubborn, wait a few minutes and try again to ensure full relief. - 3

Locate the unloader valve

Find the valve on or near the pump body, often behind a small access plate or beneath a protective shroud. Consult the manual if you’re unsure of the exact location for your model.

Tip: Take a quick photo of the setup before disassembly to aid reassembly. - 4

Inspect the exterior

Look for leaks around the valve cap, cracks in the body, or corrosion at fittings. Ensure the valve is firmly mounted and that hose connections are tight but not over-torqued.

Tip: Leaks at the cap usually indicate a need to reseal or replace the cap O-ring. - 5

Disassemble the cap if needed

Carefully remove the valve cap following the manufacturer’s procedure. Keep track of all screws and parts, and avoid scratching mating surfaces.

Tip: Use penetrating oil on stubborn screws and back them out slowly to prevent thread damage. - 6

Check spring and diaphragm or piston

Examine the spring for sagging or corrosion, the diaphragm for cracks or stiffness, and the piston for wear. Replace worn parts with OEM parts when possible.

Tip: A stiff or damaged diaphragm is a common cause of improper relief. - 7

Clean and reseat

Clean all parts with mild soap and water, rinse, and dry completely before reassembly. Ensure seals seat evenly and that the cap threads engage smoothly.

Tip: Lubricate o-rings with a tiny amount of compatible lubricant to improve seal seating. - 8

Reassemble and test at low pressure

Reinstall the valve cap and any covers. Reconnect hoses as needed, then run the unit at low pressure to confirm normal operation before returning to full duty.

Tip: Watch for leaks and verify the trigger releases pressure promptly. - 9

Evaluate results and plan next steps

If the unit shows stable pressure and no leaks, you’ve likely resolved the issue. If problems persist, consider replacing the valve or consulting a service technician.

Tip: Keep spare seals on hand for quick future maintenance.

Quick Answers

What is the function of an unloader valve on a pressure washer?

The unloader valve redirects water back to the pump when you release the trigger, regulating pressure and protecting the pump and seals from damage due to over-pressurization.

The unloader valve relieves pressure by routing water back to the pump whenever you release the trigger, protecting the system from damage.

How can I tell if the unloader valve is bad?

Common signs include erratic pressure, sudden surges, leaks at the cap, or the pump running hot. If you notice one or more of these, inspect the valve and related seals.

Look for sudden pressure changes, leaks, or an overheating pump to suspect a bad valve.

Can I adjust an unloader valve to fix pressure?

Some units allow minor adjustments, but many models require factory settings or replacement parts. Refer to the manual and avoid forcing adjustments that can damage seals.

Only adjust if the manual allows it; otherwise, replacement parts are usually safer.

Should I replace the whole pump or just the valve?

If the valve shows wear or recurrent issues, replacing the valve or its seals is often more cost-effective than replacing the entire pump. Use OEM parts when possible.

Often you can replace the valve or seals rather than the entire pump.

How often should I inspect the unloader valve?

Inspect during routine maintenance, especially after heavy use or if you notice performance changes. Annual checks are common, but follow your model’s guidance.

Check it during regular maintenance or after heavy use.

What if I can’t locate the valve?

Consult the user manual or manufacturer’s online diagrams for your model. If you’re unsure, contact a professional technician to avoid improper disassembly.

If you can’t find it, refer to the manual or seek professional help.

Watch Video

Key Takeaways

- Identify valve location before disassembly

- Depressurize system completely to stay safe

- Inspect spring, diaphragm, and seals for wear

- Test at low pressure first after reassembly

- Replace worn components promptly to prevent pump damage