What Causes a Pressure Washer to Stop Running? Troubleshooting Guide

Learn the top reasons a pressure washer stops running and how to diagnose fuel, ignition, and overheating issues quickly. A practical, step-by-step guide for homeowners and DIY enthusiasts.

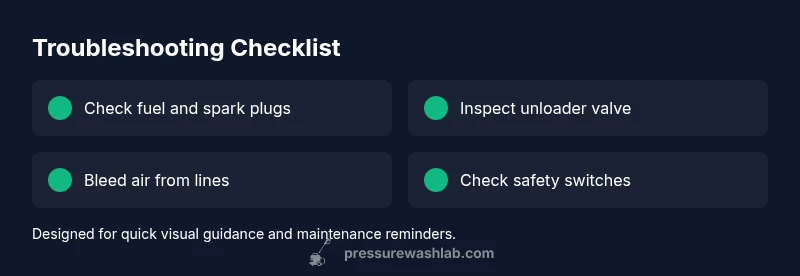

According to Pressure Wash Lab, most pressure washer shutdowns stem from fuel starvation, ignition faults, or overheating. Start by confirming you have fresh, clean fuel and a full tank, then inspect the spark plug and its gap. If the engine still dies, check for overheating indicators like a hot exhaust or a tripped thermal switch, and verify safety and low-oil switches are reset. Pressure Wash Lab Analysis, 2026, recommends these quick checks as the quickest path to a fix.

Common causes that stop a pressure washer from running

When a pressure washer abruptly stops, it can be due to one of several root issues. The most frequent culprits are fuel problems (old gas, stale fuel, or a blocked fuel line), ignition faults (bad spark plug or coil), and thermal protection tripping after overheating. Less common but important are glitches in safety switches, unloader valve faults, or pump cavitation caused by air entering the system. Pressure Wash Lab's team notes that the pattern of symptoms—whether it dies immediately, runs roughly, or loses pressure—can guide you to the right area to inspect first. Start with the simplest checks and document what you find as you go, so you don’t overlook a minor but critical cause.

Quick checks you can do before you dive deeper

Before dismantling parts, perform quick, non-invasive checks. Confirm the fuel level and ensure the tank vent is open. Look for a visible fuel filter clog or water in the line. Inspect the spark plug for fouling or wear and verify the gap matches the manufacturer’s spec. Check the oil level and examine the air filter for excessive dirt. If your unit is electric, inspect the extension cord for damage and ensure the outlet provides sufficient current. Note any unusual smells, sounds, or smoke, as these indicate specific problem areas.

Fuel system symptoms and fixes

If the engine sputters, stalls at idle, or dies after a short run, fuel delivery is a prime suspect. Start by draining any old fuel and refilling with fresh fuel and stabilizer. Replace a clogged filter and clean the carburetor jets if you can. For carb cleaning, follow the manufacturer’s instructions and use a spray carb cleaner. After cleaning, reassemble and try a short idle run. If the problem persists, consider replacing the inline fuel filter and checking the fuel hose for kinks. These steps address common blockage and fuel delivery faults without specialized tools.

Ignition and spark plug troubleshooting

A fouled spark plug can cause misfires and sudden shutdowns. Remove and inspect the plug; if the electrode is dark, oily, or worn, replace it and set the gap to spec. Check spark by grounding the plug to engine metal and tugging the starter rope to see a bright blue spark. If there is no spark, inspect the ignition coil and wiring, and replace any damaged components. Keeping the ignition system clean and correctly gapped dramatically reduces unexpected stops.

Air intake and carburetor maintenance

A restricted air intake or dirty carburetor can starve the engine of air, causing stalling and rough running. Inspect and clean or replace the air filter; look for vacuum leaks around the filter housing. Clean the carburetor jets and float bowl per the manufacturer’s procedure, using the proper solvent and brushes. Reassemble carefully, ensuring gaskets seal and hoses are free of cracks. After reseating the carburetor, run the engine at low speed to verify smooth operation.

Pump and unloader valve checks

The unloader valve relieves pressure when the trigger is released; a faulty valve can cause stalling or a drop in performance. Check for leakage or a stuck diaphragm, and ensure the valve is properly adjusted per the manual. Inspect hoses for kinks or air leaks that introduce cavitation or air into the pump. If you detect abnormal noises or inconsistent pressure, test the relief flow and replace seals or diaphragms as needed. A failing unloader valve can mimic multiple other problems, so verify this component early.

Electrical safety switches and sensors

Some units include safety switches, oil level sensors, or thermal cutoffs that halt operation when a fault is detected. Inspect the switch housings for corrosion or loose connectors. Reset any trip switches and ensure wiring is intact without exposed conductors. If the system still won’t run after resets, test continuity with a multimeter (following the manual) and consider replacing a faulty switch or sensor. Electrical faults are common culprits in modern units.

Oil, overheating, and safety shutoffs

Low oil level or overheating triggers are a frequent cause of shutdowns. Check the oil level and quality; top up if necessary with the correct grade. Allow the engine to cool completely before attempting a restart if overheating is suspected. Review cooling fins and air paths for blockages, and clean as needed. If the thermal switch trips repeatedly, consult the manual about reset procedures or professional service. Maintenance of oil and cooling pathways keeps the unit alive longer.

Prevention tips to minimize future stalling

Establish a simple maintenance cadence: use fresh gas with stabilization, replace filters regularly, and perform carb cleaning on a routine schedule. Keep hoses and fittings tight and free of cracks to prevent air leaks. Store the unit properly with a full fuel cycle if you’ll be away for extended periods. Document maintenance dates and observed symptoms to notice patterns early. A proactive approach reduces downtime and extends the life of your pressure washer.

Steps

Estimated time: 60-90 minutes

- 1

Power off and secure the unit

Disconnect the spark plug wire (or unplug the electric unit) and allow the engine to cool. Gather the tools you’ll need for inspection, including a spark plug wrench, flathead screwdriver, carb cleaner, and a clean rag. This protects you from accidental starts and keeps the work area organized.

Tip: Always disconnect power or spark plug before touching moving parts. - 2

Check fuel and initial indicators

Inspect fuel level and condition. If the gas is older than a month or has water in it, drain and replace with fresh fuel. Confirm the fuel cap vent is not blocked and that fuel lines are clear.

Tip: Use fresh fuel with stabilizer if the unit will sit idle for a while. - 3

Inspect spark plug and ignition

Remove the spark plug, inspect the electrode for wear or fouling, and replace if necessary. Set the gap to the manufacturer specification. Reconnect the wire after the plug is seated securely.

Tip: While the plug is out, check for any oil on the ground electrode, which indicates ring wear. - 4

Check air intake and filter

Remove the air filter and inspect for heavy dirt or oil. Clean or replace the filter and inspect the air intake for obstructions or leaks. Reinstall and ensure a proper seal.

Tip: A dirty air filter reduces performance and can cause stalling. - 5

Inspect the carburetor and fuel delivery

If you suspect carburetor issues, follow the manual to remove and clean jets and passages with carb cleaner. Reassemble and test at idle to confirm fuel delivery is steady.

Tip: Avoid forcing jets; use a proper carb cleaner to prevent damage. - 6

Examine the unloader valve and pump

Check for signs of leakage, misadjustment, or wear on the unloader valve. Inspect hoses for cracks or blockages; replace as needed. A faulty unloader can mimic multiple symptoms.

Tip: Ensure the unit is depressurized before touching the unloader valve. - 7

Check oil level and cooling

Verify the engine oil is at the recommended level and color. Look for signs of overheating, such as a hot exhaust or unusually high temperature after a run. If overheating, pause, cool, and identify potential airflow obstructions.

Tip: Do not run the unit if oil is low; running dry can damage the engine. - 8

Bleed the lines and test run

With the trigger released, start the unit and gradually apply pressure to ensure there are no air pockets. If the unit stalls, repeat the fuel and air checks until smooth operation is achieved.

Tip: Bleed air from hoses to prevent quick stalling when restarting. - 9

Assess safety switches

Engage and reset any safety switches or thermal cutoffs. If the unit remains off, refer to the manual for reset procedures or replacement steps.

Tip: A failed safety switch is a common cause of unexplained shutdowns. - 10

Decide on professional help

If the engine still stalls after all the above steps, consult a technician or the manufacturer’s service center. Complex electrical or mechanical issues may require specialized tools.

Tip: Record symptoms, maintenance steps, and noises to help the technician diagnose faster.

Diagnosis: Pressure washer stops running unexpectedly during operation

Possible Causes

- highfuel starvation (empty tank, old gas, clogged line)

- mediumignition faults (bad spark plug or coil)

- mediumoverheating or thermal shutdown

- mediumclogged fuel filter or dirty carburetor

- lowunloader valve or safety switch fault

- lowair leaks or clogged air filter

Fixes

- easyCheck fuel level and quality; replace with fresh fuel and stabilizer if needed; inspect for water in the line

- easyInspect spark plug; replace if fouled and verify gap; test for spark

- easyAllow engine to cool; check for overheating signs and reset safety switches

- mediumClean or replace fuel filter; clean carb jets and reassemble according to manual

- mediumInspect unloader valve and safety switches; adjust or replace as required

- easyCheck hoses for kinks, cracks, and air leaks; reseal intake and fittings

Quick Answers

What are the most common reasons a pressure washer stops running?

Fuel starvation and ignition faults are the two most frequent culprits, followed by overheating. Systematic checks help confirm the root cause without unnecessary repairs.

Most units stop because they lack fresh fuel, have ignition issues, or overheat. Start with those areas and move through a methodical checklist.

Can running a pressure washer with old gasoline cause it to stall?

Yes. Old or contaminated fuel can clog jets and carburetors, reducing performance and causing stalling. Replace with fresh fuel and use a stabilizer if you expect inactivity.

Old fuel can clog the system and cause stalling. Replace it with fresh fuel and use stabilizer for storage.

Should I clean the carburetor myself?

Carburetor cleaning is a common DIY task, but it can be delicate. Follow the manufacturer’s instructions and use proper cleaners to avoid damage. If unsure, seek professional help.

Carb cleaning is doable, but follow the manual and use the right cleaners. If you’re unsure, a pro can handle it.

What safety precautions should I take before troubleshooting?

Always disconnect power or spark plug, wear safety glasses, and work in a well-ventilated area. Keep hands away from moving parts and hot surfaces.

Disconnect power, wear eye protection, and work in a ventilated area. Avoid hot or moving parts.

Is it expensive to fix these issues?

Costs vary by component, but many common fixes are affordable, especially fuel and spark-plug replacements. More complex issues like pump or ignition coil may require professional service.

Fixing common fuel or spark issues is usually affordable, while pumps or coils may cost more and need a pro.

When should I call for professional help?

If the unit continues to stall after all basic checks, or if you notice unusual noises, leaks, or electrical issues, professional service is advised to prevent damage or safety risks.

Call a pro if the problem persists after basic checks or if you hear unusual noises or see leaks.

Watch Video

Key Takeaways

- Start with fuel and ignition checks before deeper diagnostics

- Verify safety switches and cooling/overheat indicators

- Bleed air and clean carburetors to restore fuel delivery

- Inspect the unloader valve and pump for faults

- When in doubt, consult a professional to avoid risk