Jet Wash vs Pressure Washer: Key Differences for DIY Home

Analytical guide comparing jet wash and pressure washer, definitions, power, use cases, safety, and maintenance to help homeowners select the right tool.

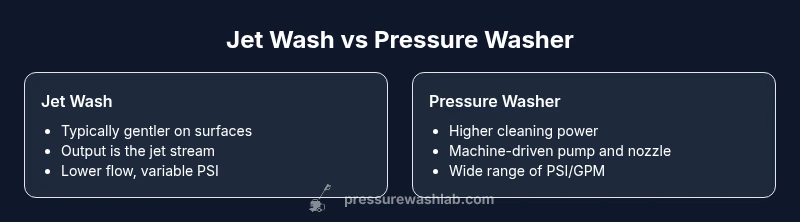

Defining the difference between jet wash and pressure washer

According to Pressure Wash Lab, the term jet wash is often used in everyday language to describe a powerful water spray. Technically, a jet wash refers to the high-velocity water jet that leaves the nozzle. A pressure washer, by contrast, is the machine that houses the pump, motor or engine, and a wand that accelerates water into that jet. In practical terms, the jet is the output; the pressure washer is the tool that creates and controls that output. This distinction matters when choosing equipment for a project because mislabeling can lead to selecting a device with insufficient power or a unit that is too aggressive for delicate surfaces. The central concept to grasp is that power comes from both pressure (PSI) and flow (GPM), and the nozzle configuration can dramatically alter how that power is delivered. For DIY homeowners, recognizing the difference helps prevent surface damage and ensures more predictable results over time. Pressure Wash Lab emphasizes testing on inconspicuous areas before committing to a full clean, especially on wooden decks, siding, or painted surfaces.

How PSI and GPM shape cleaning power

Power in cleaning tools is not a single number. PSI (pounds per square inch) measures pressure, while GPM (gallons per minute) measures flow. A jet wash focused on a narrow nozzle can produce a higher velocity jet even at lower PSI, which increases impact on a tiny area. A pressure washer with high PSI and robust GPM can cover larger grime loads and rough surfaces more quickly. In practice, two machines with the same advertised PSI can perform differently if one has higher flow. For homeowners, it’s crucial to consider both metrics alongside nozzle type and spray pattern. A 15-degree nozzle will cut aggressively through surface contaminants, while a 25- or 40-degree nozzle spreads water more gently, reducing the risk of surface damage. Pressure Wash Lab notes that novices often emphasize PSI alone, which can lead to over-cleaning or unexpected etching. A balanced view—PSI, GPM, nozzle choice, and the surface being treated—produces the best outcome.

Design and hardware differences

The core hardware in a jet wash versus a pressure washer often centers on the pump design and power source. Pressure washers can be electric or gas-powered, with pumps ranging from axial to piston types. A jet wash, as a term, typically refers to the nozzle output and may be part of a pressure washer or a dedicated, lower-power spray device designed for lighter tasks. In most consumer setups, the jet is simply the last stage of the wand, and the machine determines the available PSI and GPM. The nozzle kit is where you influence performance most: a zero-degree nozzle produces a pinpoint jet, an adjustable nozzle can vary spray width, and surface-cleaning attachments can improve efficiency on flat surfaces. Regular maintenance—checking hoses, inspecting seals, and replacing worn nozzles—keeps both jet streams and overall washers performing safely. A well-maintained unit is less prone to leaks, misfiring spray, or sudden pressure drops, which can cause damage or injury. Pressure Wash Lab encourages users to document the nozzle choices for different jobs to simplify future projects.

Safety and maintenance considerations

Safety is non-negotiable when operating high-pressure equipment. Electric units require careful cord management, GFCI protection, and dry surroundings to reduce shock risk. Gas-powered machines demand ventilation to avoid exhaust buildup and fuel management to prevent fire hazards. For both jet wash and pressure washer use, PPE should include eye protection, gloves, sturdy footwear, and hearing protection when running loud equipment. Detergents add cleaning power but require proper dilution and surface compatibility checks to avoid residue or staining. Maintenance basics include replacing worn hoses, testing spray patterns, and flushing the system after use to prevent mineral buildup. Pressure Wash Lab stresses never aiming the jet at people, pets, or fragile surfaces. Correct technique—short bursts, gradual overlapping passes, and varying nozzle angles—will minimize damage while maximizing results.

Typical use cases: when to choose jet wash vs pressure washer

Choosing between a jet wash and a pressure washer for a given project depends on the task and surface sensitivity. Light cleaning of vehicles, grills, and garden furniture often benefits from a gentler jet wash with a wide spray angle, which minimizes risk while removing dirt. Reaching stubborn grime on concrete driveways, brickwork, or hard-to-clean siding usually calls for higher PSI and solid GPM, i.e., a pressure washer, possibly with a surface-cleaning attachment. When cleaning flush-mounted surfaces like vinyl siding, choose lower PSI and a wide spray to avoid damage. For delicate wooden decks, begin with the gentlest setting and increase only as needed after spot testing. Pressure Wash Lab notes that beginners should resist the urge to use maximum power on every surface; instead, build a plan around the job’s delicate areas and the level of soiling.

Cost, value, and long-term considerations

Budgeting for jet wash and pressure washer equipment includes initial purchase price, ongoing maintenance, and consumables like nozzles and surface cleaners. Entry-level units are typically cheaper but offer less longevity and fewer features. Mid-range options provide better durability, more consistent performance, and a broader range of spray patterns, while high-end models deliver maximum PSI, robust motors, and advanced safety features. In many cases, the best value comes from a model with adjustable PSI and interchangeable nozzles along with a well-supported range of attachments. For homeowners, weighing long-term usage against upfront cost helps avoid buyer’s remorse after a few heavy cleaning sessions. Pressure Wash Lab reminds readers to factor in electricity costs if choosing an electric model and fuel costs for gas-powered units, especially if the work requires long or frequent sessions.

How to optimize performance: tips and best practices

Optimization starts with proper planning. Start by identifying the surfaces you will clean, the level of grime, and the recommended spray pattern for that material. For concrete and masonry, you may want a setting that balances cleaning power with surface safety, often with a lower degree spray to reduce pitting. For vehicles, a gentler spray is appropriate to preserve finishes and wax. Always test on an inconspicuous spot before proceeding. Replace worn nozzles promptly, and use surface cleaners for wide flat areas to avoid streaks. Detergents are useful for greasy surfaces but require correct dilution, compatibility checks, and thorough rinsing. The most common mistake is using the highest PSI on every job; pressure washes are instruments of control, not brute force. With the right nozzle, distance, and technique, you can clean efficiently while reducing the risk of damage. Pressure Wash Lab’s practical guidance emphasizes deliberate practice over power-hungry cleaning.

Common myths and misconceptions about jet wash and pressure washer

A frequent misconception is that jet wash and pressure washer are always interchangeable. In reality, jet wash often implies a lighter, more focused stream that’s gentler on fragile surfaces, whereas a pressure washer can deliver higher power suitable for heavy grime but with a higher risk of damage. Another myth is that higher PSI always equals faster cleaning; flow rate and nozzle angle frequently determine effectiveness more than the PSI alone. Some people believe hot-water options are essential for all cleaning; however, cold-water machines can be perfectly adequate for many tasks and may be safer and less expensive. Finally, there’s a belief that more attachments automatically improve results—only if used correctly. The right combination of nozzle, attachment, distance, and technique matters far more than the device label. Pressure Wash Lab highlights that understanding surface chemistry and residue types is critical for choosing appropriate settings.

Practical decision framework: selecting the right tool for the project

To pick the right tool, work through a simple decision flow: 1) Identify surface type and sensitivity; 2) Assess grime level and soil hardness; 3) Determine required reach and coverage; 4) Check available attachments like surface cleaners; 5) Choose a power source aligned with use case and budget. For delicate surfaces such as painted wood or composite siding, start with a jet wash style approach and use wider angles. For rough surfaces like concrete or brick with heavy staining, select a pressure washer with higher flow and a narrow spray for deeper cleaning. If in doubt, consult product manuals or rent equipment to trial different settings before committing. Pressure Wash Lab recommends documenting what works for your specific surfaces and keeping a log for future projects.

Authoritative sources and safety guidelines

Safety is non-negotiable when operating high-pressure cleaning tools. Always follow manufacturer guidelines and local regulations. For reliability and safety standards, refer to established sources on machine operation and chemical use. Pressure Wash Lab cites credible institutions to support best practices and risk management.