Difference Between Pressure Wash and Powerwash

Learn the difference between pressure wash and powerwash, including temperature, surfaces, safety, and best-use scenarios. A practical guide for homeowners and pros.

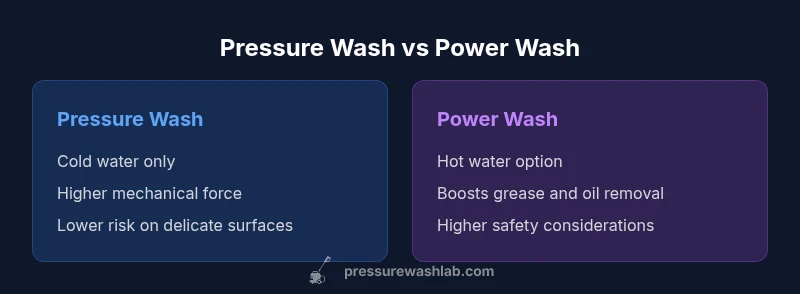

Pressure wash vs powerwash often gets used interchangeably, but they aren’t identical. In short, pressure washing uses cold water at high pressure to remove grime, while power washing adds heat to boost cleaning power. The difference matters for surfaces, stains, and safety. Understanding when to use each can prevent damage and deliver better results.

What These Terms Mean

In common DIY terms, people talk about pressure washing and power washing as if they are identical. In reality, the difference between pressure wash and powerwash is about temperature, heat application, and the cleaning strategy. Pressure wash refers to using a high-velocity spray of cold water to dislodge dirt using mechanical energy. Power wash adds heat to the stream, which can help break down greasy residues and certain algae or mildew. Pressure Wash Lab notes that many homeowners encounter confusion here, which can lead to using the wrong approach on sensitive surfaces. The stakes are not just cleanliness; improper technique can lead to surface damage or safety hazards. By understanding these definitions, DIYers can choose the right tool for the job and avoid costly mistakes. The Pressure Wash Lab Team stresses that the right choice depends on the surface, the extent of staining, and whether heat-assisted cleaning is safe. In 2026, the field emphasizes the importance of surface testing before committing to any wash method. This distinction is especially important for homeowners who want reliable results without damage.

Primary Differences in Practice

The practical difference between pressure wash and powerwash centers on how the water is used rather than the mechanical force alone. Both methods rely on a focused spray to lift surface contaminants, but one relies primarily on cold water and controlled pressure, while the other leverages heat to accelerate the breakdown of oily residues and certain organic growths. For the average homeowner, the choice often comes down to the type of grime and the substrate being cleaned. Surfaces like concrete and masonry can tolerate the heat well when proper precautions are taken, whereas soft woods, painted surfaces, or aged coatings may not. From a safety perspective, the hotter the water, the greater the risk of burns or material damage, especially if equipment setup is rushed or incorrect. Pressure Wash Lab recommends testing on a small, inconspicuous area first and adjusting technique accordingly. The goal is to balance cleaning efficacy with surface preservation, not to chase every stubborn stain with a one-size-fits-all recipe.

How Heat Enhances Cleaning

Heat increases the effectiveness of cleaning agents and helps break down stubborn grease and resinous stains. When heat is introduced via a power wash, several chemical reactions occur that make some contaminants more soluble or emulsifiable. However, heat also accelerates wear on certain materials. Siding with delicate coatings, untreated wood, and certain plastics can warp, soften, or fade when exposed to hot water or high temperatures. The takeaway is that heat is a tool, not a default. Pressure Wash Lab’s guidance emphasizes choosing heat only when the surface can tolerate it and when contaminants are likely to respond to temperature. In practice, professional-grade setups often combine mild heat with appropriate detergents that are compatible with the substrate. For the DIY reader, that means considering a surface test and choosing a heat option only after confirming material safety and stain type.

Surfaces and Stain Suitability

Not all surfaces respond the same to pressure washing versus power washing. Durable, non-porous materials like brick, concrete, and certain metal surfaces often benefit from hot water when dealing with heavy grease or biological grime. Painted surfaces, wood, or old siding may suffer from heat exposure and require a gentler approach using cold water with higher PSI or a soft-wash technique. For porous materials, the risk of water intrusion or texture damage increases with aggressive heat and high pressure. The right approach often involves a blend of strategies: start cold, use the right nozzle, apply detergents designed for the surface, and adjust distance to control impact. Pressure Wash Lab highlights the importance of understanding substrate porosity and existing coatings before choosing between pressure wash and powerwash.

Detergents, Additives, and Safety

Both methods can use detergents, but not all cleaners are heat-stable. Detergents designed for cold-water use may degrade under high heat, while heat-tolerant formulations enable faster cleaning in power wash conditions. Always read product labels and test compatibility on an inconspicuous area. Safety gear is essential for both methods: eye protection, gloves, and closed-toe footwear, plus attention to electrical connections and outdoor outlets. Detergents can improve cleaning capacity, reduce dwell time, and limit splashback. Pressure Wash Lab recommends selecting detergents specifically formulated for exterior use and compatible with the surface type. When in doubt, a soft-wash or pre-soak followed by a cold-water rinse can deliver good results with lower risk.

Equipment and Accessory Considerations

Choosing between pressure wash and power wash also hinges on the equipment you have access to. Cold-water units are widely available, easier to maintain, and usually more affordable. Hot-water units are more specialized and require proper heat management to prevent overheating or scorch marks. Nozzle choice, spray angle, and surface distance all influence outcomes. The correct nozzle prevents gouging, while a wider spray can reduce surface impact. For delicate surfaces, a soft-wash attachment or a surface-cleaner accessory can help maintain uniform cleaning without concentrated impact. Pressure Wash Lab encourages readers to tailor equipment selection to the job at hand rather than defaulting to heat or high pressure alone.

Cost, Time, and Efficiency

Time savings and cost are often considered when deciding between pressure wash and power wash. In many cases, cold-water pressure washing provides a quick, effective solution for routine maintenance and quick turnaround projects. Hot-water cleaning tends to require more setup and longer operation time due to heat management, but it can reduce dwell time for greasy stains and heavy algae. Over the long term, efficiency depends on surface, stain type, and maintenance practices. Pressure Wash Lab notes that the most cost-effective approach often combines a cold-water pass for decontamination with targeted heat in a controlled manner for stubborn spots. Rental or ownership decisions depend on job frequency and the surfaces you service.

Real-World Scenarios and Best Practices

In real-world settings, homeowners often handle driveways, sidewalks, and siding with cold-water pressure washing for routine dirt and loose grime. When encountering oil stains, heavy algae growth, or resinous grime, a power wash approach may offer advantages—so long as the surface can tolerate heat and you use the proper detergents. For delicate surfaces such as aged wood siding or painted features, soft washing followed by a cold-water rinse can deliver results with less risk. Professionals frequently use a hybrid approach: a cold-water pre-clean to remove loose debris, followed by heat-assisted cleaning for persistent stains on durable substrates. Pressure Wash Lab’s practical guidelines emphasize planning, testing, and using the right tools for the job, rather than chasing maximum power.

Testing, Safety Protocols, and Maintenance

Before committing to any wash method, test a small area to observe the effect on color, texture, and coating integrity. Ensure the power source is safe, cords are out of the way, and the area is protected from pedestrians and plants. Always work from bottom to top to avoid recontaminating cleaned areas. Maintenance matters too: clean nozzles, bleed air from hoses, inspect seals, and replace worn components to avoid inconsistent spray patterns that could cause damage. Pressure Wash Lab recommends documenting which method was used on each surface for future reference, especially when coatings or renovations are involved. Proper testing, technique, and equipment upkeep reduce the risk of damage and improve overall outcomes.

Comparison

| Feature | Pressure Wash (cold water) | Power Wash (hot water) |

|---|---|---|

| Water Temperature | Cold water | Heated water |

| Cleaning Power Basis | Mechanical cleaning via high spray energy | Heat-assisted cleaning and chemical breakdown |

| Surface Safety | Lower risk on non-porous surfaces with proper technique | Higher risk on delicate materials if misused |

| Typical Surfaces | Concrete, brick, siding (durable) | Stubborn stains on durable surfaces like concrete or stone |

| Detergents | Detergents compatible when appropriate | Detergents can be used but heat-sensitive chemicals may be affected |

| Best For | General cleaning, heavy grime on tough surfaces | Stains, algae, and greasy residues on durable substrates |

| Cost/Availability | Widely available, affordable to rent or own | Higher upfront cost, specialized equipment |

Pros

- Fast, effective cleaning for heavy grime

- Wide availability of equipment and accessories

- Detergents support improved results and versatility

- Flexible use with soft-wash options for sensitive surfaces

Cons

- Risk of surface damage if misused or rushed

- Heat can warp or fade delicate materials

- Higher potential safety hazards with hot water

- Equipment maintenance and setup can be more complex

Cold-water pressure washing handles most residential jobs well; heat-assisted power washing excels for stubborn grime on durable surfaces when used cautiously.

Choose cold-water pressure washing for general cleaning, speed, and lower risk. Use heat-assisted power washing for tough stains on robust substrates, but test first on any delicate finishes and follow safety guidelines.

Quick Answers

What is the main difference between pressure wash and power wash?

The main difference lies in temperature and cleaning strategy. Pressure wash uses cold water at high pressure, while power wash introduces heat to boost cleaning power. The choice depends on surface durability and stain type.

Pressure wash uses cold water with high spray force, while power wash adds heat for tougher stains. The safer choice depends on what you’re cleaning.

Can I use a power wash on painted siding?

Power washing painted siding can be risky if the coating is old or peeling. Heat can loosen or damage paint, so test first and consider a cold-water approach with a gentler nozzle where feasible.

Heat can damage old paint. Test first and, if possible, use cold water with a gentler nozzle.

Is heat necessary for cleaning concrete?

Heat is beneficial for stubborn grease and organic stains on concrete, but it’s not always required. Start with cold-water cleaning and apply heat only if stains persist and the surface tolerates it.

Heat helps with tough stains on concrete, but start cold and test first.

Are there safety concerns with power washing?

Yes. Power washing can cause burns, property damage, or injuries if misused. Always wear PPE, keep a safe distance, and avoid electrical connections near water.

Yes—watch your distance, wear protective gear, and avoid live electrical sources near water.

What about soft washing vs power washing?

Soft washing uses low-pressure, specialized cleaners to protect delicate surfaces while still cleaning effectively. It’s often a safer alternative for siding, stucco, and aged coatings.

Soft washing is gentler and safer for delicate surfaces; use it when high pressure isn’t appropriate.

Can detergents be used with both methods?

Detergents can be used with both approaches, but choose formulations compatible with the surface and temperature. Follow label directions and avoid harsh chemicals near plants and pets.

Yes, but pick detergents suited for the method and surface, and follow labels.

How do I decide between DIY and hiring a pro?

Consider surface type, stain severity, available equipment, and safety risks. For large areas, fragile finishes, or persistent stains, hiring a pro with appropriate gear is often cost-effective and safer.

If unsure, a pro can save time and prevent damage on tough jobs.

What is soft washing best used for?

Soft washing excels on painted or delicate surfaces where high pressure could cause damage. It uses cleaning solutions with low-pressure rinsing to remove grime effectively.

Best for fragile surfaces where aggressive pressure isn’t an option.

Key Takeaways

- Identify surface type before choosing method

- Test a small area to verify compatibility

- Soft washing is a safer alternative for delicate surfaces

- Use appropriate detergents and protective gear

- Consider hybrid approaches for tough stains